Acidic dye-fixing agent and preparation method thereof

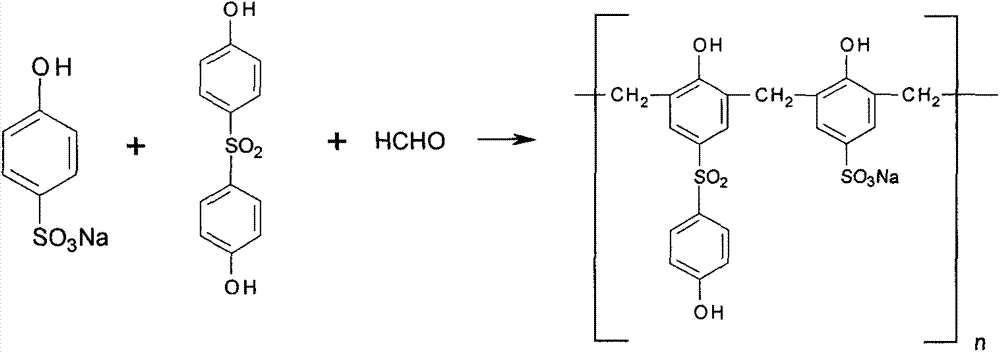

The technology of an acidic color-fixing agent and a catalyst is applied in the field of textile auxiliaries, which can solve the problems of complicated operation steps, and achieve the effects of simple preparation process, low cost and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

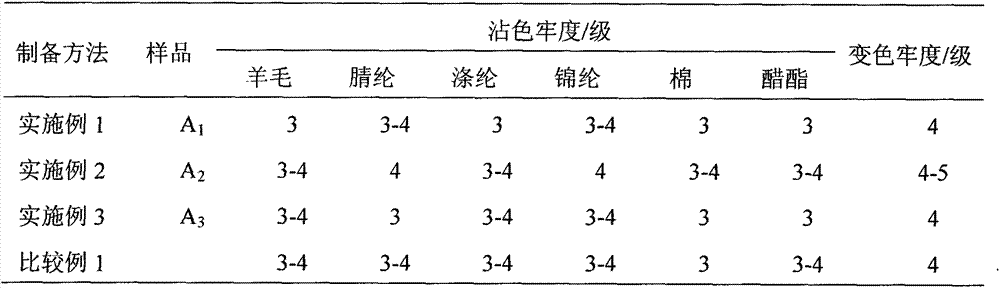

[0015] Add bisphenol S (0.01mol) and phenol sulfonate (0.01mol) into a 100ml three-neck flask equipped with a magnetic stirrer, condenser, and constant pressure dropping funnel, add 5ml of water, 1ml of ethanol and sodium hydroxide solution (10g / L) 0.8ml, start stirring and heat up to 70°C, add 0.03mol formaldehyde drop by drop with a constant pressure dropping funnel, gradually raise the temperature (10°C / 30min) to 100°C after the addition, keep warm for 2 hours, and the reaction is over After cooling down, take out the generated solution and filter, the filtrate is the acid color fixing agent sample A 1 .

Embodiment 2

[0017] Add bisphenol S (0.01mol) and phenol sulfonate (0.015mol) into a 100ml three-neck flask equipped with a magnetic stirrer, a condenser, and a constant pressure dropping funnel, and add 5ml of water, 1ml of ethanol and sodium hydroxide solution (50g / L) 1ml, start stirring and heat up to 70°C, add 0.0375mol formaldehyde drop by drop with a constant pressure dropping funnel, gradually raise the temperature (10°C / 30min) to 120°C after the addition, keep it warm for 2 hours, after the reaction is over Cool down, take out the generated liquid and filter, the filtrate is the acid color fixing agent sample A 2 .

Embodiment 3

[0019] Add bisphenol S (0.005mol) and phenol sulfonate (0.015mol) into a 100ml three-necked flask equipped with a magnetic stirrer, a condenser tube, and a constant pressure dropping funnel, add 5ml of water, 1ml of ethanol and sodium hydroxide solution (50g / L) 0.8ml, start stirring and heat up to 70°C, add 0.03mol formaldehyde drop by drop with a constant pressure dropping funnel, gradually raise the temperature (10°C / 30min) to 140°C after the addition, keep warm for 2 hours, and the reaction is over After cooling down, take out the generated solution and filter, the filtrate is the acid color fixing agent sample A 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com