Ultralow-twist velvet cotton fabric and weaving and dyeing process thereof

An ultra-low, lint-cotton technology, used in textiles and papermaking, knitting, dyeing, etc., can solve the problem of softness, bulkiness and moisture absorption performance not meeting the requirements, the strength and life of fabrics, and affecting the softness and dryness of cotton fibers. It can overcome problems such as hand feel, and achieve the effect of overcoming easy color fading, conducive to the diffusion of moisture and moisture, and good color fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: a kind of ultra-low-twisted blue velvet cotton cloth, by containing the A yarn of 50% long-staple cotton and 50% combed cotton and containing the B yarn of 50% long-staple cotton and 50% combed cotton through tight The 32S / 1 twist produced by Saifang is 17.4 twist / inch pure cotton ultra-low twist yarn, and then the ultra-low twist blue velvet cotton raw cloth is obtained by weaving the pure cotton ultra-low twist yarn and other yarns, and the cloth is Pure color left slanted two-piece garment; the ultra-low-twist blue velvet cotton fabric is obtained after dyeing, post-treatment, color fixing, softening and shaping processes.

[0041] Further, in order to make the woven fabric maintain better fabric strength under ultra-low twist, the average length of the long-staple cotton is 35-37mm, and the average length of the combed cotton is 29-30mm; the pure cotton The thickness of the ultra-low twist yarn is 32S / 1.

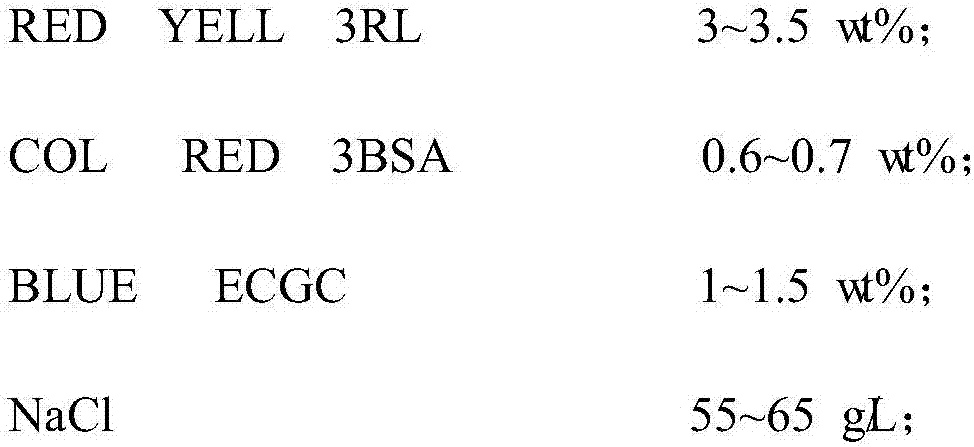

[0042] The weaving and finishing process of t...

Embodiment 2

[0069] Embodiment 2: a kind of ultra-low-twisted blue velvet cotton cloth, by containing the A yarn of 70% long-staple cotton and 30% combed cotton and containing the B yarn of 50% long-staple cotton and 50% combed cotton through tight The 40S / 1 twist produced by Saifang is 19.5 twist / inch pure cotton ultra-low twist yarn, and then weaved by the pure cotton ultra-low twist yarn and 30D spandex to obtain the ultra-low twist blue velvet cotton raw cloth, the cloth is Pure color rack 1X1 rib; the ultra-low-twist blue velvet cotton raw fabric is made of ultra-low-twist blue velvet cotton fabric after dyeing, post-treatment, color fixing, softening and shaping processes.

[0070] Further, in order to make the woven fabric maintain better fabric strength under ultra-low twist, the average length of the long-staple cotton is 35-37mm, and the average length of the combed cotton is 29-30mm; the pure cotton The thickness of the ultra-low twist yarn is 40S / 1.

[0071] The present invent...

Embodiment 3

[0098] Embodiment 3: A kind of ultra-low-twisted blue velvet cotton cloth, by containing the A yarn of 100% long-staple cotton and the B yarn that contains 50% long-staple cotton and 50% combed cotton, make 32S / 1 The pure cotton ultra-low twist yarn with a twist of 17.4 twist / inch, the average length of long-staple cotton is 35-37mm, and the average length of combed cotton is 29-30mm; the thickness of the pure cotton ultra-low twist yarn is It is 32S / 1; the ultra-low-twist blue velvet cotton original cloth is obtained by weaving the pure cotton ultra-low-twist yarn and 75D / 36F polyester yarn, and the cloth is a solid jacquard rib; the ultra-low-twist blue velvet cotton The original fabric is dyed, post-treated, fixed, softened and shaped to produce ultra-low-twisted blue velvet cotton fabric.

[0099] The weaving and finishing process of the above-mentioned ultra-low twist blue velvet cotton cloth comprises the following steps:

[0100] (11) Spinning: the proportion of a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com