Continuous spinning viscose filament yarn oiling agent composition

A technology of filament oil agent and composition, which is applied in the direction of plant fibers, textiles and papermaking, and improved hand-feeling fibers, etc. It can solve the problems of difficult degradation of polyethanol pulp, increased fiber breakage rate, and high environmental protection pressure, etc. problem, to achieve the effect of easy desizing and dyeing, soft cloth surface and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

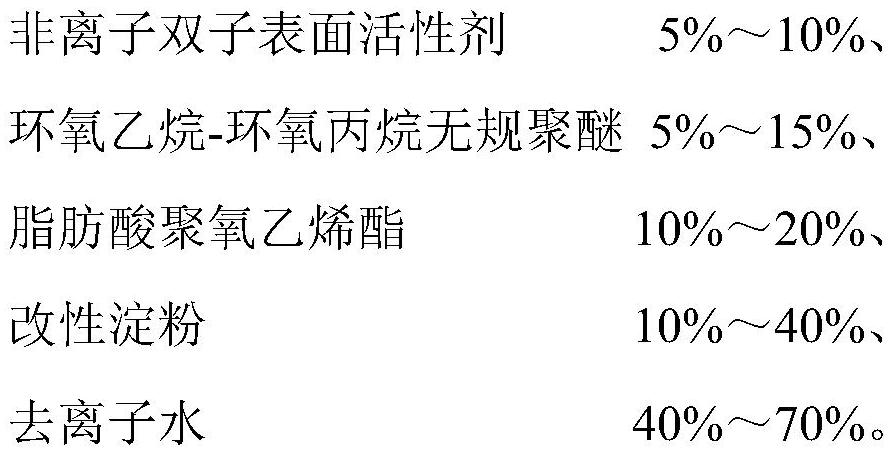

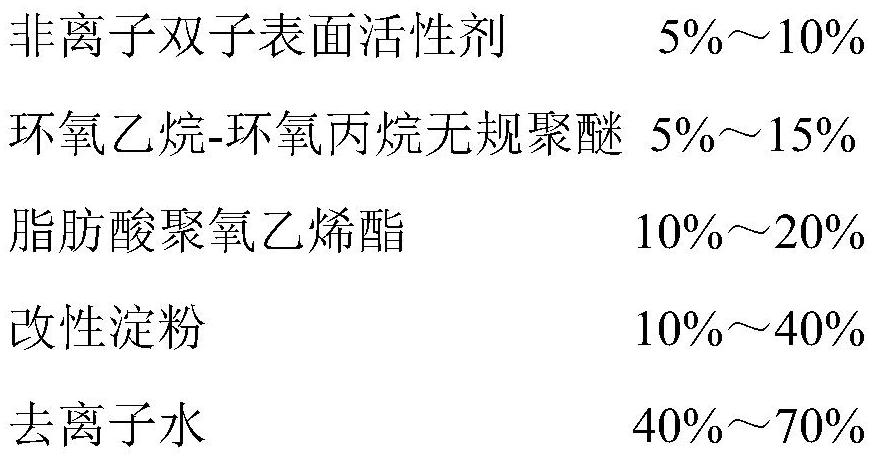

[0019] (1) a continuous spun viscose adhesive filament oil composition, made of the following raw materials by weight percentage:

[0020]

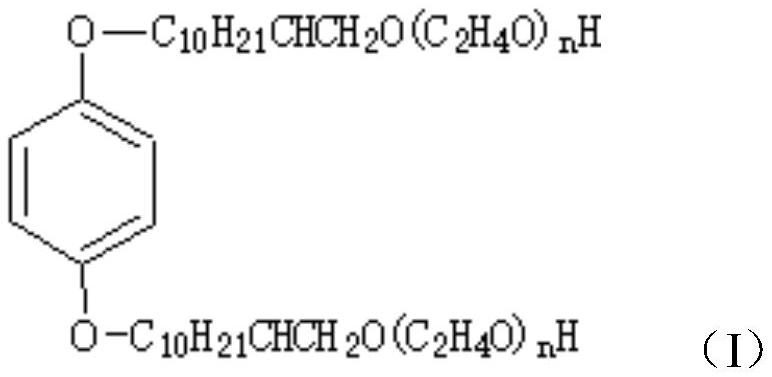

[0021] The nonionic gemini surfactant is,

[0022] The ethylene oxide-propylene oxide random polyether has a molecular weight of 1500 and a molar ratio of ethane to propane (EO / PO) of 2.

[0023] The fatty acid polyoxyethylene ester is, C 10 h 23 COO(EO) 16 H.

[0024] (2) The preparation method is as follows:

[0025] Raise the temperature of deionized water to 60°C, first add sulfonic acid type quaternary ammonium amphoteric starch, stir for 20 minutes, then add nonionic gemini surfactant, ethylene oxide-propylene oxide random polyether and fatty acid polyoxyethylene ester in sequence After mixing and stirring for 30 minutes, a continuous spunbond filament oil composition was obtained.

Embodiment 2

[0027] (1) a continuous spun viscose adhesive filament oil composition, made of the following raw materials by weight percentage:

[0028]

[0029] The nonionic gemini surfactant is,

[0030] The ethylene oxide-propylene oxide random polyether has a molecular weight of 2800 and a molar ratio of ethane to propane (EO / PO) of 6.

[0031] The fatty acid polyoxyethylene ester is, C 18 h 37 COO(EO) 26 H.

[0032] (2) The preparation method is as follows:

[0033] Warm up deionized water to 60°C, first add phosphate-type quaternary ammonium-based amphoteric starch, stir for 15 minutes, then add nonionic gemini surfactant, ethylene oxide-propylene oxide random polyether and fatty acid polyoxyethylene ester in sequence, After mixing and stirring for 50 minutes, a continuous spunbond filament oil composition was obtained.

Embodiment 3

[0035] (1) a continuous spun viscose adhesive filament oil composition, made of the following raw materials by weight percentage:

[0036]

[0037] The nonionic gemini surfactant is,

[0038] The ethylene oxide-propylene oxide random polyether has a molecular weight of 1200 and a molar ratio of ethane to propane (EO / PO) of 4.

[0039] The fatty acid polyoxyethylene ester is, C 12 h 25 COO(EO) 14 H.

[0040] (2) The preparation method is as follows:

[0041] Warm up deionized water to 50°C, first add sulfonic acid type quaternary ammonium amphoteric starch, stir for 15 minutes, then add nonionic gemini surfactant, ethylene oxide-propylene oxide random polyether and fatty acid polyoxyethylene ester in sequence After mixing and stirring for 50 minutes, a continuous spunbond filament oil composition was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com