Method for improving color fastness of photochromic fabric

A technology for color fastness and fabric, applied in the field of textile dyeing and finishing, can solve problems such as limited research, and achieve the effect of small color reduction and good color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add propyltrimethoxysilane (50%) and ethanol (30%) into the beaker in turn, stir on the stirrer to make them mix evenly, and the stirring speed is 230-450 rpm; under stirring Add hydrochloric acid (0.005-1.0mol / L) solution dropwise to the mixture; stir at room temperature for 24 hours.

[0029] (2) Dip the dyed fabric twice in the finishing solution (2-3kg / cm2), and then dry it in a blast oven at 120°C to 170°C for several minutes.

[0030] (3) Test the fastness of the dyed fabric, the details are as follows:

[0031] ①Rubbing fastness test:

[0032] According to GB / T3920-1997 test method for fastness to rubbing of textiles.

[0033] ②Soaping fastness test:

[0034] According to GB3921-83 test method for color fastness to washing of textiles (evaluate the color fastness to washing of fabrics by testing the staining of adjacent fabrics and the fading of original fabrics)

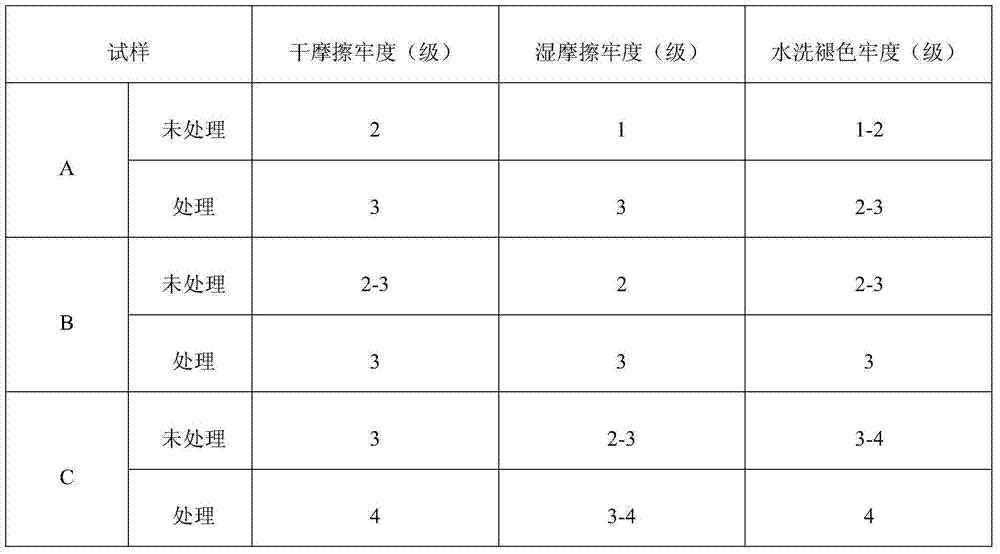

[0035] (4) Example

[0036] Explanation of different color changing fabric numbers

[003...

Embodiment 2

[0044] (1) Add ethyl orthosilicate (50%), propyltrimethoxysilane (0.1%), and ethanol (30%) into the beaker in sequence, and stir on the stirrer to make them mix evenly, and the stirring speed is at 230~450 rpm; add hydrochloric acid (0.005~1.0mol / L) solution dropwise to the mixture under stirring; stir at room temperature for 24 hours.

[0045] (2) Dip the dyed fabric twice in the finishing solution (2-3kg / cm2), and then dry it in a blast oven at 120°C to 170°C for several minutes.

[0046] (3) Test the fastness of the dyed fabric, the details are as follows:

[0047] ③Rubbing fastness test:

[0048] According to GB / T3920-1997 test method for fastness to rubbing of textiles.

[0049] ④ Soaping fastness test:

[0050] According to GB3921-83 test method for color fastness to washing of textiles (evaluate the color fastness to washing of fabrics by testing the staining of adjacent fabrics and the fading of original fabrics)

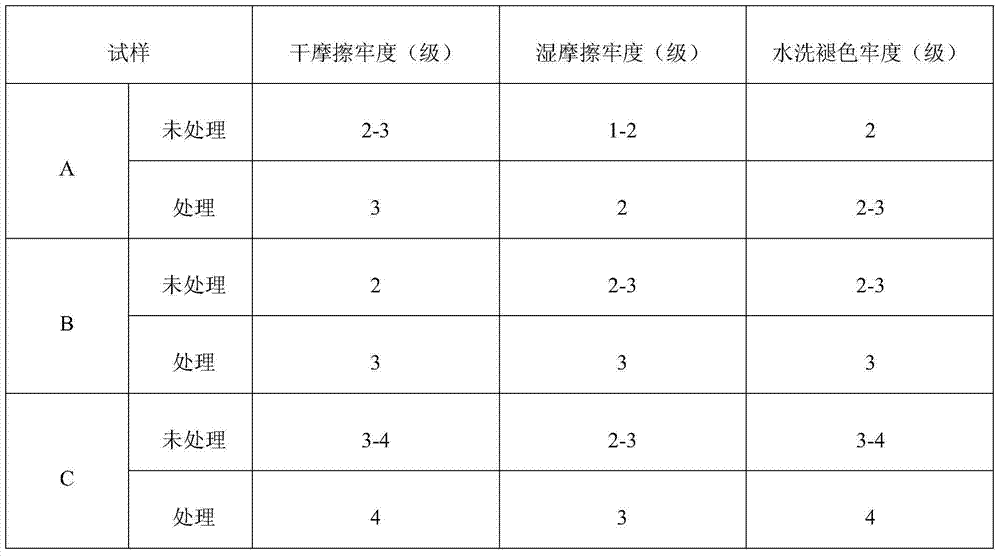

[0051] (4) Example

[0052] Explanation of differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com