Montan wax washing soap and preparation method thereof

The technology of montan wax and laundry soap is applied in the field of montan wax laundry soap and its preparation, and achieves the effects of easy rinsing, good color fixing ability and strong decontamination ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

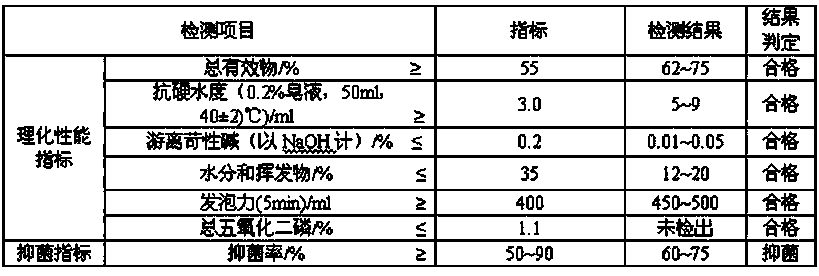

Image

Examples

Embodiment 1

[0032] The montan wax laundry soap described in this implementation is prepared from the following raw materials, and each raw material and weight percentage are:

[0033] Crude Montan Wax 35%; Coconut Oil 14.98%; Sodium Hydroxide (AR) 10%;

[0034] Composite surfactant 5%: sodium dodecylbenzene sulfonate 2%, alkyl polyglucoside 3%;

[0035] Calcium soap dispersant 0.02%: dodecyl dimethyl betaine 0.01%, LBD-1 dispersant 0.01%;

[0036] Bactericide 3%: tea saponin 1%, sodium fulvic acid 2%;

[0037] Compound enzyme 2%: alkaline protease 0.4%, alkaline cellulase 0.4%, alkaline amylase 0.4%, alkaline lipase 0.4%, alkaline pectinase 0.4%;

[0038] Other additives 30%: natron 8%, sodium carbonate 1%, borax 3%, 4-formylphenylboronic acid 0.5%, glycerol 7.85%, anti-redeposition agent 445 / 445N 1%, citric acid 5 %, sodium carboxymethylcellulose 1%, ester quaternary ammonium salt 2%, color fixing agent CHROMABOND? S-100 0.5%, mint essence 0.05%, fluorescent whitening agent 0.1%.

[...

Embodiment 2

[0044] The montan wax laundry soap described in this implementation is prepared from the following raw materials, and each raw material and weight percentage are:

[0045] Defatted montan wax 75%; olive oil 5.69%; sodium hydroxide (AR) 12%;

[0046] Calcium soap dispersant 2%: tetradecyl dimethyl betaine 0.5%, LBD-1 dispersant 1.5%;

[0047] Fungicide 0.3%: tea saponin 0.1%, sodium fulvic acid 0.2%;

[0048] Compound enzyme 0.01%: alkaline protease 0.001%, alkaline cellulase 0.003%, alkaline amylase 0.002%, alkaline lipase 0.002%, alkaline pectinase 0.002%;

[0049] Other additives 5%: natron 2%, sodium carbonate 0.02%, borax 0.05%, 4-formylphenylboronic acid 0.01%, glycerin 1.85%, anti-redeposition agent 445 / 445N 0.03%, citric acid 0.5% %, sodium carboxymethyl cellulose 0.01%, ester quaternary ammonium salt 0.5%, color fixing agent CHROMABOND? S-100 0.01%, jasmine essence 0.01%, fluorescent whitening agent 0.01%.

[0050] The deionized water directly required for the react...

Embodiment 3

[0055] The montan wax laundry soap described in this implementation is prepared from the following raw materials, and each raw material and weight percentage are:

[0056] Oxidized refined montan wax 56.36%; sodium hydroxide (AR) 11%;

[0057] Composite surfactant 4%: sodium fatty alcohol polyoxyethylene ether sulfate 2%, alkyl polyglucoside 2%;

[0058] Calcium soap dispersant 0.06%: LBD-1 dispersant 0.06%;

[0059] Fungicide 0.5%: tea saponin 0.2%, sodium fulvic acid 0.3%;

[0060] Compound enzyme 0.08%: alkaline protease 0.01%, alkaline cellulase 0.02%, alkaline amylase 0.02%, alkaline lipase 0.01%, alkaline pectinase 0.02%;

[0061] Other additives 28%: natron 6%, sodium carbonate 1%, borax 3%, 4-formylphenylboronic acid 0.5%, glycerol 7.85%, anti-redeposition agent 445 / 445N 1%, citric acid 5 %, sodium carboxymethyl cellulose 1%, ester quaternary ammonium salt 2%, color fixing agent CHROMABOND? S-100 0.5%, rose essence 0.05%, fluorescent whitening agent 0.1%.

[0062] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com