Process of producing color laminated board

A production method and color layer technology, which are applied in the field of wood processing, can solve the problems of easy fading, decolorization, environmental pollution, etc., and achieve the effects of good color fixation, good environmental protection, and not easy to fade or decolorize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

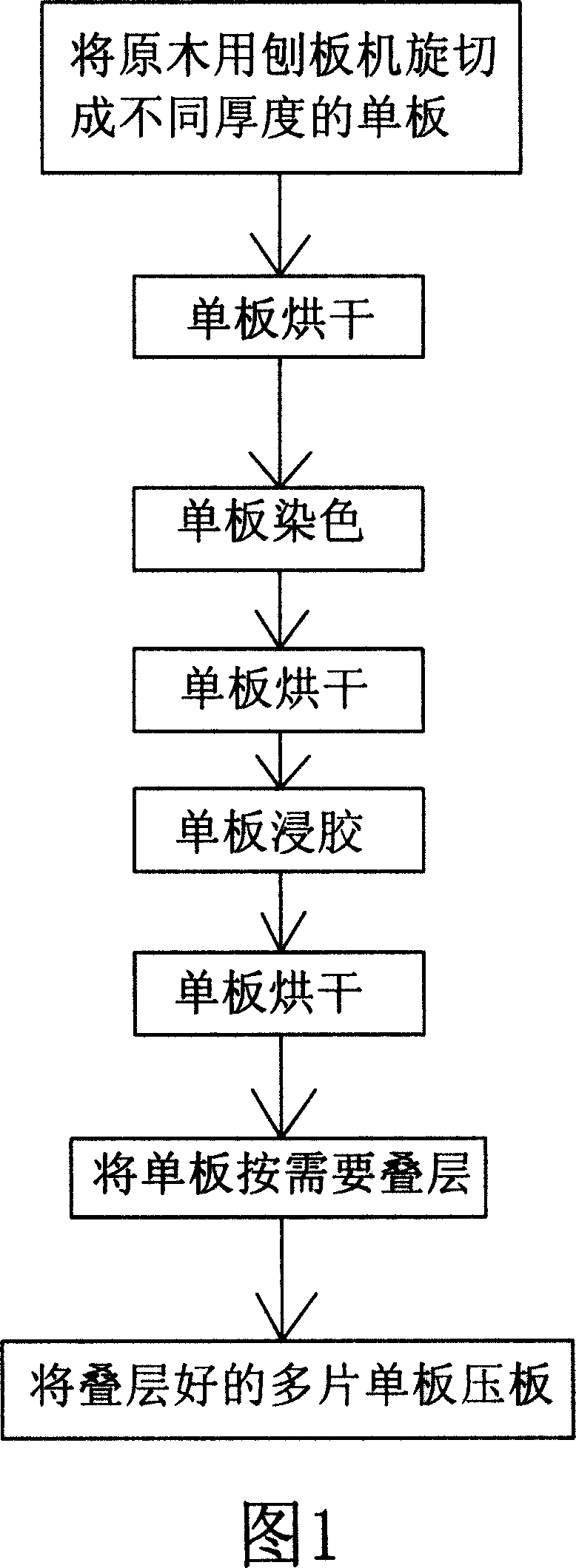

[0025] A method for producing a colored laminate, the method comprising the following steps:

[0026] (1) log is rotary-cut into veneer of 0.5mm thickness with planer;

[0027] (2) drying the veneer obtained in step 1 in a temperature environment of 60°C;

[0028] (3) Dyeing the dried veneer;

[0029] (4) Dry the dyed veneer in a temperature environment of 60°C;

[0030] (5) dipping the veneer obtained through step 4 into glue;

[0031] (6) Dry the dipped veneer in a temperature environment of 40°C;

[0032] (7) Laminate the veneers obtained in step 6 as required;

[0033] (8) Press the laminated multiple veneers.

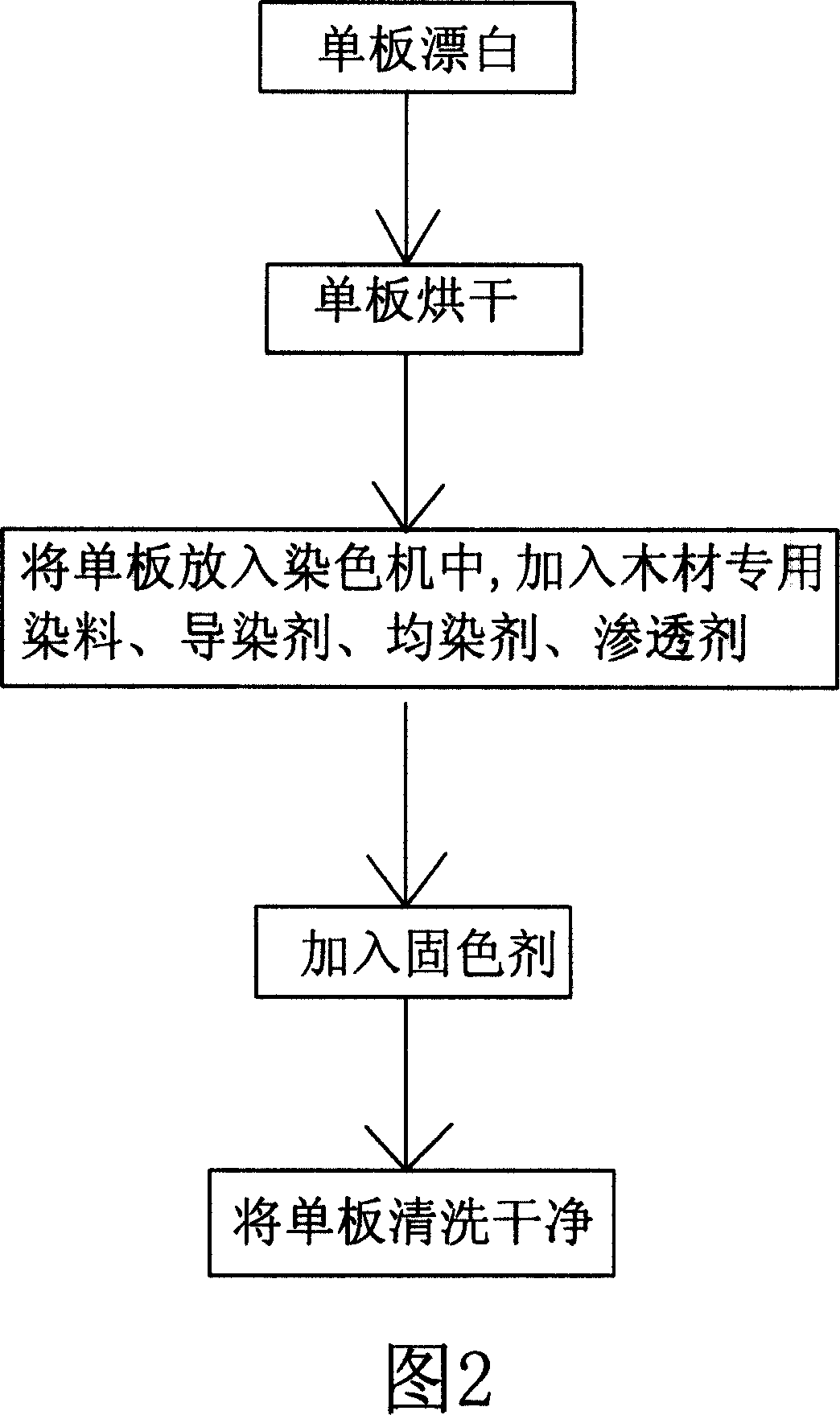

[0034] The above step 3 specifically includes the following steps: (a) put the veneer in the bleaching solution to bleach for 60 minutes, and control the temperature at 100°C; (b) put the bleached veneer in an oven to dry until the humidity is 8 ~12 degrees, the oven temperature is controlled at 60 degrees; (c) put the veneer obtained in step b into the dyein...

Embodiment 2

[0039] A method for producing a colored laminate, the method comprising the following steps:

[0040] (1) Rotate the log into veneers with a thickness of 0.75 mm with a planer;

[0041] (2) drying the veneer obtained in step 1 in a temperature environment of 90°C;

[0042] (3) Dyeing the dried veneer;

[0043] (4) Dry the dyed veneer in a temperature environment of 90°C;

[0044] (5) dipping the veneer obtained through step 4 into glue;

[0045] (6) Dry the dipped veneer in a temperature environment of 60°C;

[0046] (7) Laminate the veneers obtained in step 6 as required;

[0047] (8) Press the laminated multiple veneers.

[0048] The thickness of the veneer described in step 1 above is 0.75mm;

[0049] The above step 3 specifically includes the following steps: (a) Put the veneer in the bleaching solution to bleach for 75 minutes, and control the temperature at 95°C; (b) Put the bleached veneer in an oven to dry until the humidity is 8 ~12 degrees, the oven temperatur...

Embodiment 3

[0054] A method for producing a colored laminate, the method comprising the following steps:

[0055] (1) logs are cut into veneers with a thickness of 1mm with a planer;

[0056] (2) drying the veneer obtained in step 1 in a temperature environment of 130°C;

[0057] (3) Dyeing the dried veneer;

[0058] (4) Dry the dyed veneer in a temperature environment of 130°C;

[0059] (5) dipping the veneer obtained through step 4 into glue;

[0060] (6) Dry the dipped veneer in a temperature environment of 80°C;

[0061] (7) Laminate the veneers obtained in step 6 as required;

[0062] (8) Press the laminated multiple veneers.

[0063]The thickness of the veneer described in step 1 above is 1mm.

[0064] The above step 3 specifically includes the following steps: (a) put the veneer in the bleaching solution for 90 minutes and control the temperature at 90°C; (b) put the bleached veneer in an oven to dry until the humidity is 8 ~12 degrees, the oven temperature is controlled at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com