Transferring printing process for natural fabric

A natural fiber transfer printing technology, applied in transfer printing method, printing process, printing, etc., can solve the problem of poor performance of natural fibers such as moisture absorption and perspiration, air permeability, high printing cost, and inability to print "photographic" patterns and other problems, to achieve good coloring and color fixing performance, good coloring rate, and rich transitional layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

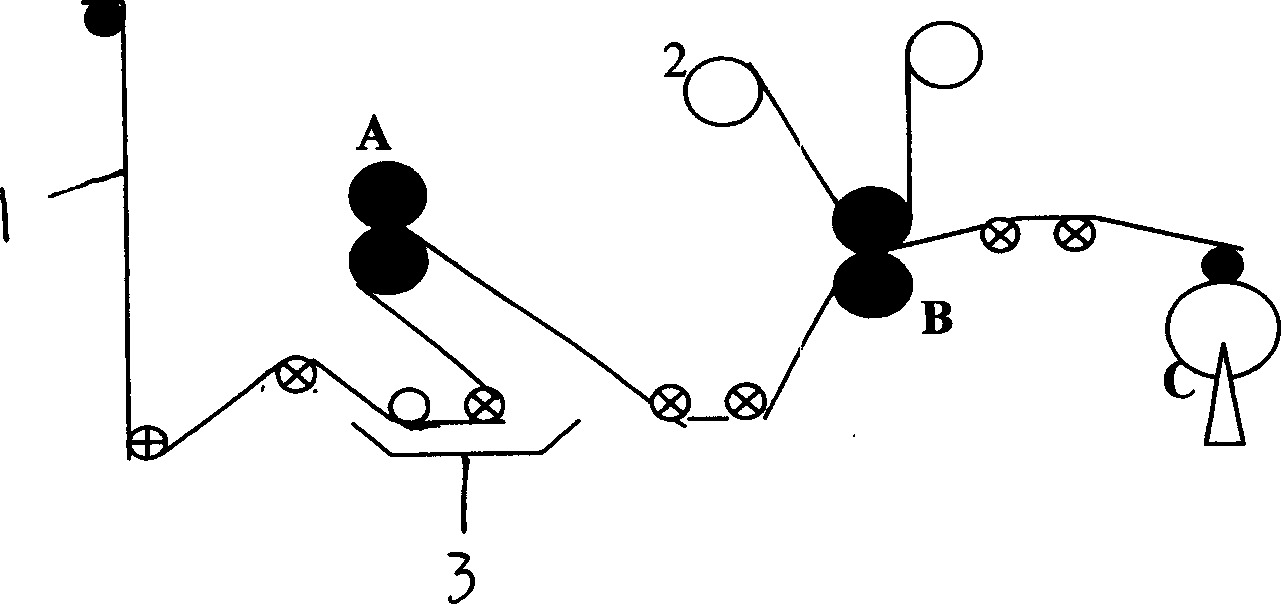

Image

Examples

Embodiment Construction

[0018] Requirements for gray fabric: smelting, refining and whitening to become mercerized fabric.

[0019] A transfer printing process for natural fiber fabrics, which includes the following steps

[0020] (1) Coating process, that is, coating the surface of the web;

[0021] (2) The printing process, that is, printing the surface of the web to make transfer printing paper, and the dyes used for printing are reactive dyes;

[0022] (3) Transfer process, the gray cloth of natural fiber fabric is soaked in lye and then rolled dry, and the transfer printing paper and the gray cloth are pressurized to free the dye on the paper and transfer and penetrate into the inside of the gray cloth.

[0023] Described coating comprises the composition of following weight ratio

[0024] Coating material: 1-50%

[0025] Nonionic surfactant: 1-20%

[0026] Preservatives 1-10%

[0027] The rest are organic solvents.

[0028] Described coating material comprises stearate, polyethylene glyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com