Fur illumination radiation bleaching device

A technology of light radiation and light-emitting devices, which is applied in the fields of dyeing, textiles and papermaking, and fiber processing, and can solve problems such as high production costs, large energy consumption, difficult control of indoor temperature, humidity, and steam pressure, and meet production needs , Easy and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

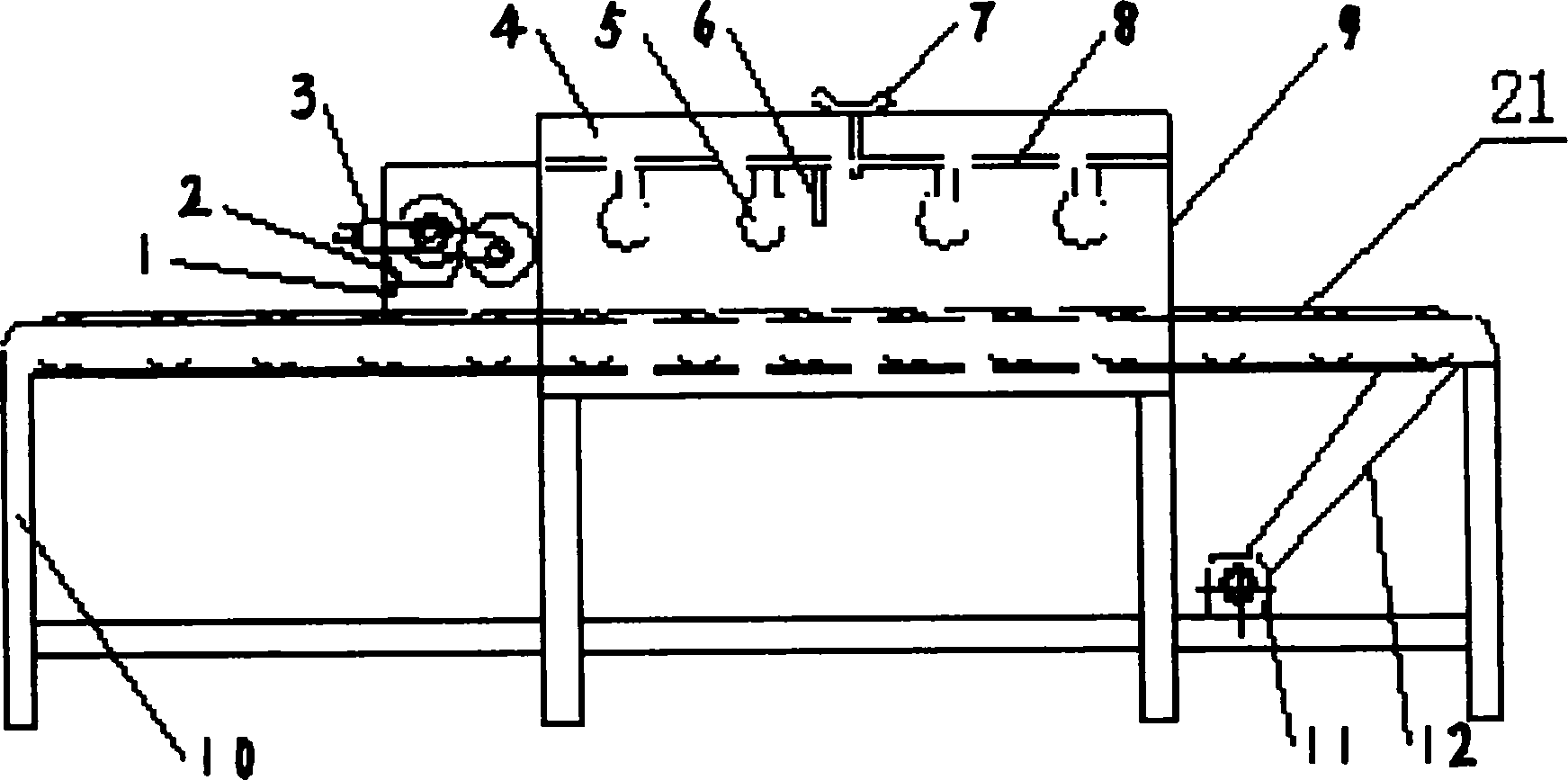

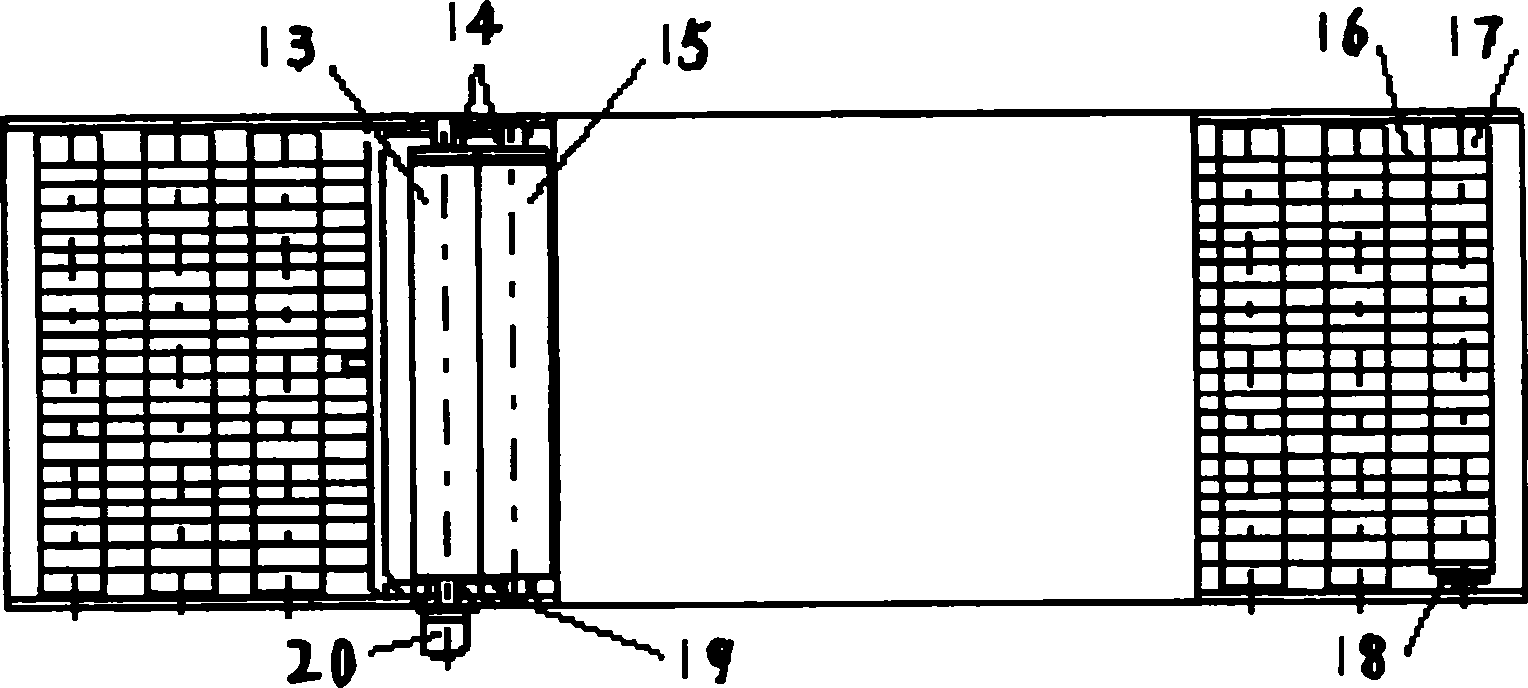

[0010] see figure 1 , 2, the present invention is provided with transmission device 21 on frame 10, and this transmission device 21 comprises several conveying rollers 17 that equidistantly is arranged on frame 10, and several nylon conveyor belts 16 are encircled on the conveying roller 17, convey Belt 16 is driven by conveyor belt motor 11 through chain 12, sprocket wheel 18, transmission roller 17 to drive its circular movement; Both sides are also provided with adjusting rod 3, brush roller 15 is arranged on the adjusting rod 3, brush roller motor 20 is connected with upper liquid roller 13, and makes upper liquid roller 13 and brush roller 15 rotate synchronously through a pair of gears 14, adjusts Bar 3 can make the brush roller 15 swing a certain angle around the axis of the upper liquid roller 13, thereby adjusting the distance between the brush roller 15 and the nylon conveyor belt 16, to adapt to processing different kinds of furs, the upper liquid roller 13 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com