PE pipe extrusion molding device

A molding device and driving unit technology, applied in the field of PE pipes, can solve the problems of irregular PE pipes, inability to adjust the wall thickness of PE pipes, air bubbles, etc., and achieve the effects of improving processing efficiency, preventing spots and ensuring quality effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways of claim defined and covered.

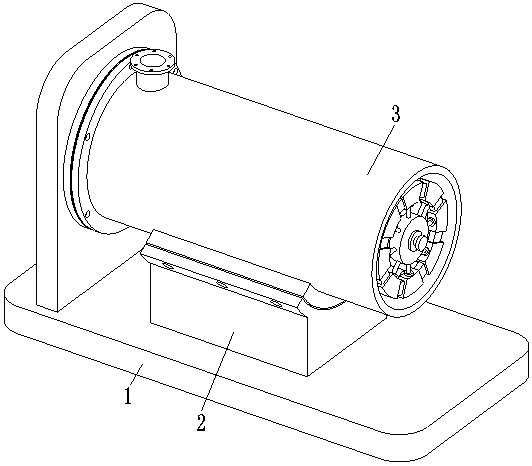

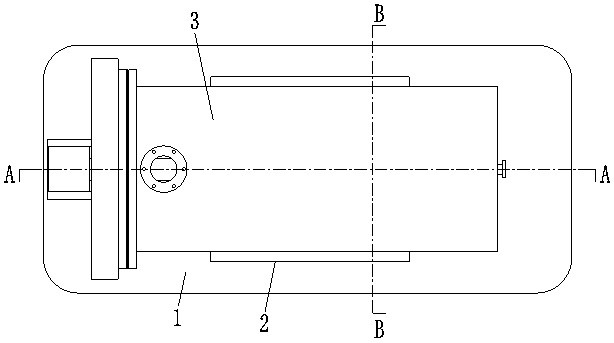

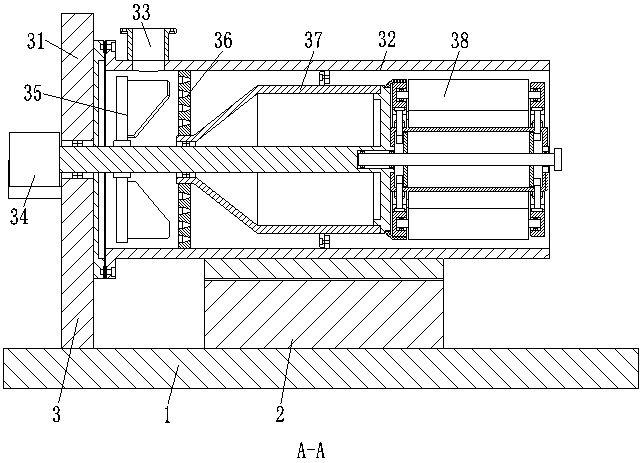

[0032] like Figure 1 to 8 As shown, a PE tube extruded molding device includes a bottom plate 1, a support frame 2, and a extruded assembly 3, and a support frame 2 is mounted in the upper end of the bottom plate 1, and extrusion is mounted on the upper left side of the bottom plate frame 1. Component 3, in the middle of the extruded assembly 3 is located at the upper end of the support frame 2.

[0033] The extruded assembly 3 includes a baffle 31, a fixing cylinder 32, a feed tube 33, a driving unit 34, a stirring unit 35, a filter plate 36, a cone frame 37, and a round unit 38, the upper end of the bottom plate. On the left side, the baffle 31 is mounted, and a connection flange is provided on the right side of the baffle 31, and the fixing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com