Method for workpiece platform micro moving part mechanical parameter estimation

A technology of mechanical parameters and workpiece table, applied in calculation, electrical digital data processing, aerodynamic improvement, etc., can solve the problem of difficult position of the center of mass of the micro-moving part of the workpiece table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

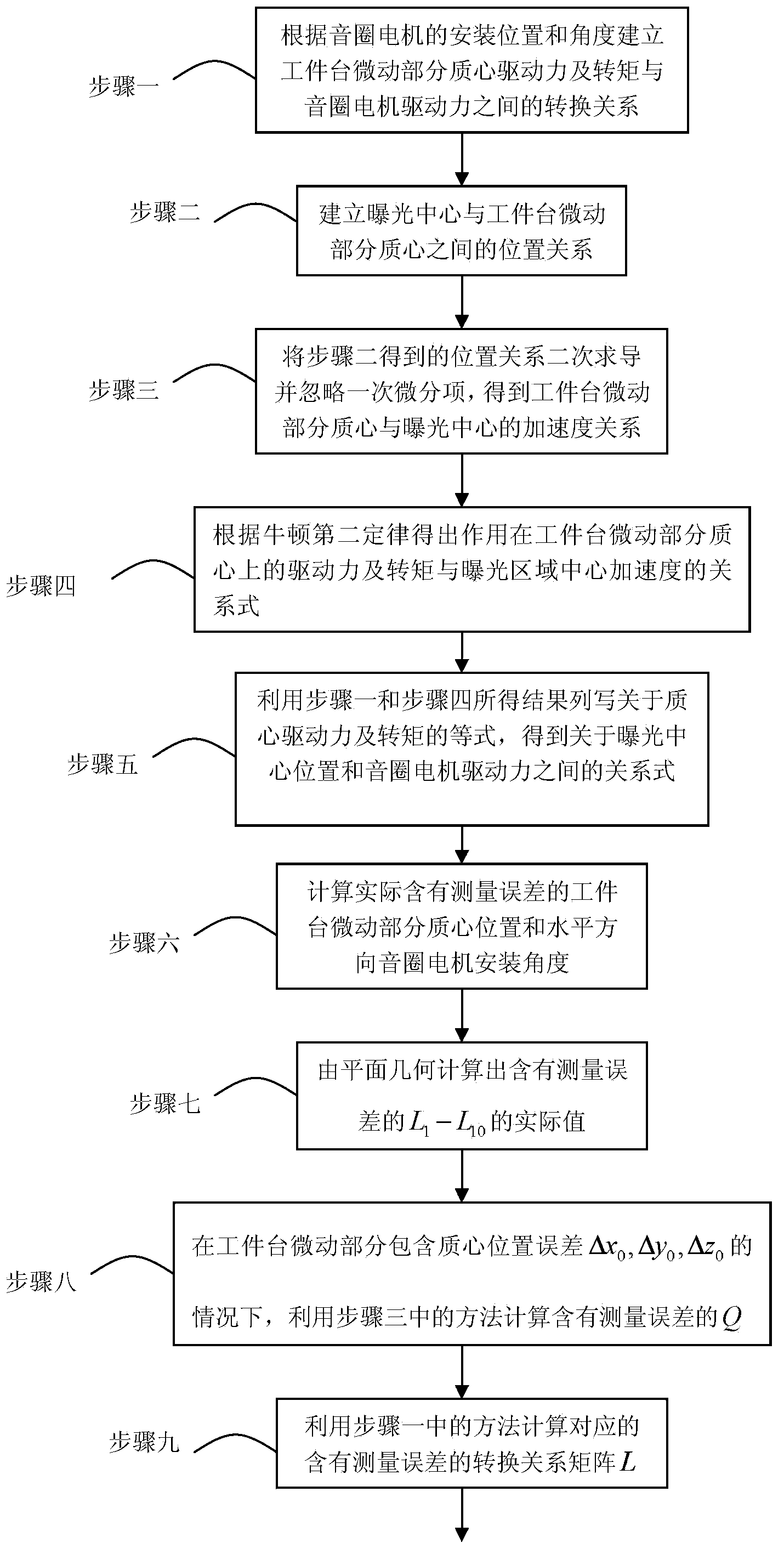

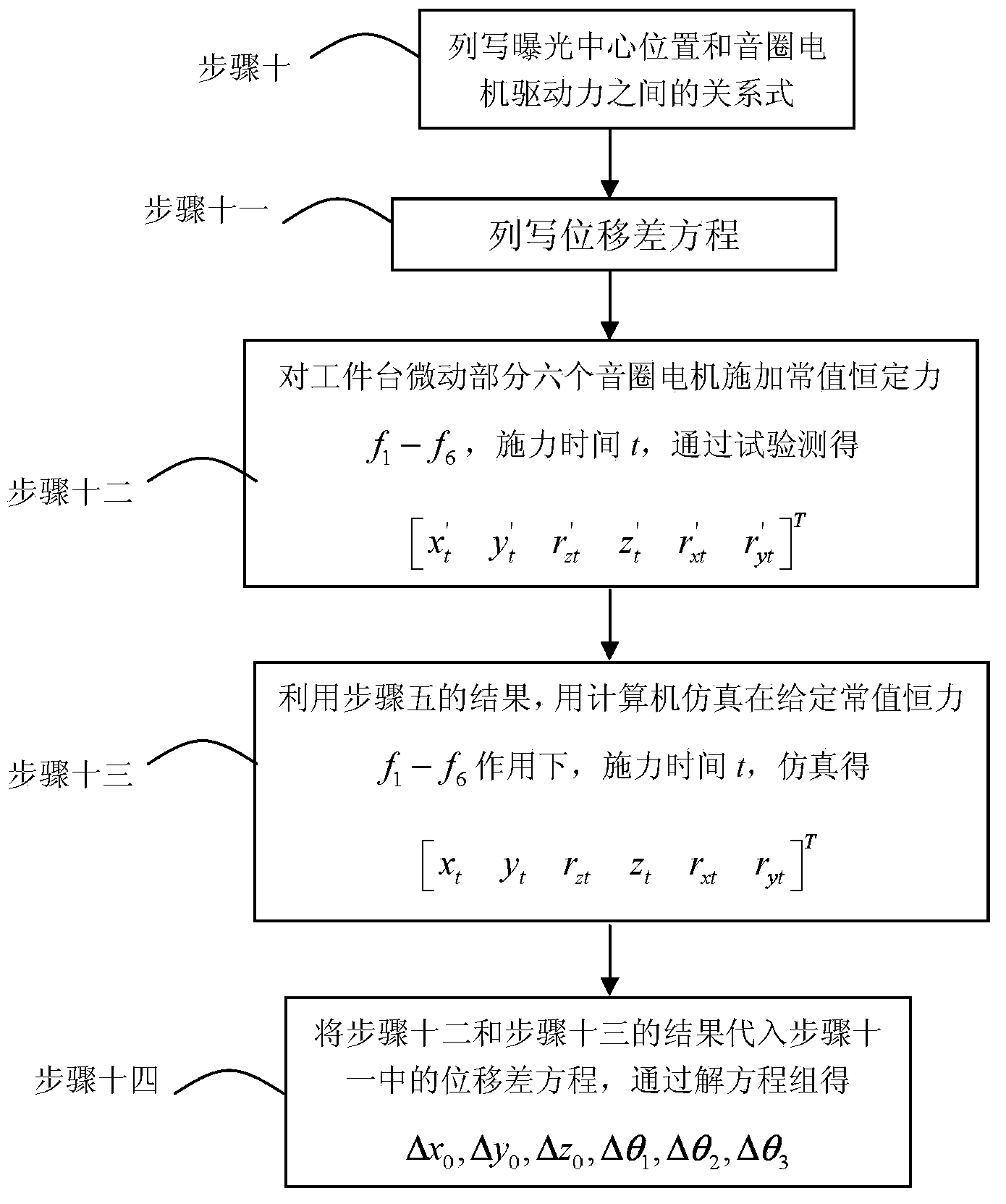

[0037] Embodiment 1: A method for estimating the mechanical parameters of the micro-movement part of the workpiece table in this embodiment is implemented in the following steps:

[0038] 1. According to the installation position and angle of the voice coil motor, establish the conversion relationship between the center-of-mass driving force and torque of the micro-movement part of the workpiece table and the driving force of the voice coil motor;

[0039] 2. Establish the positional relationship between the exposure center and the center of mass of the micro-movement part of the workpiece table;

[0040] 3. Secondary derivation of the positional relationship obtained in step 2 and ignoring the primary differential item to obtain the acceleration relationship between the center of mass of the micro-moving part of the workpiece table and the exposure center;

[0041] 4. According to Newton's second law, the relationship between the driving force and torque acting on the center ...

specific Embodiment approach 2

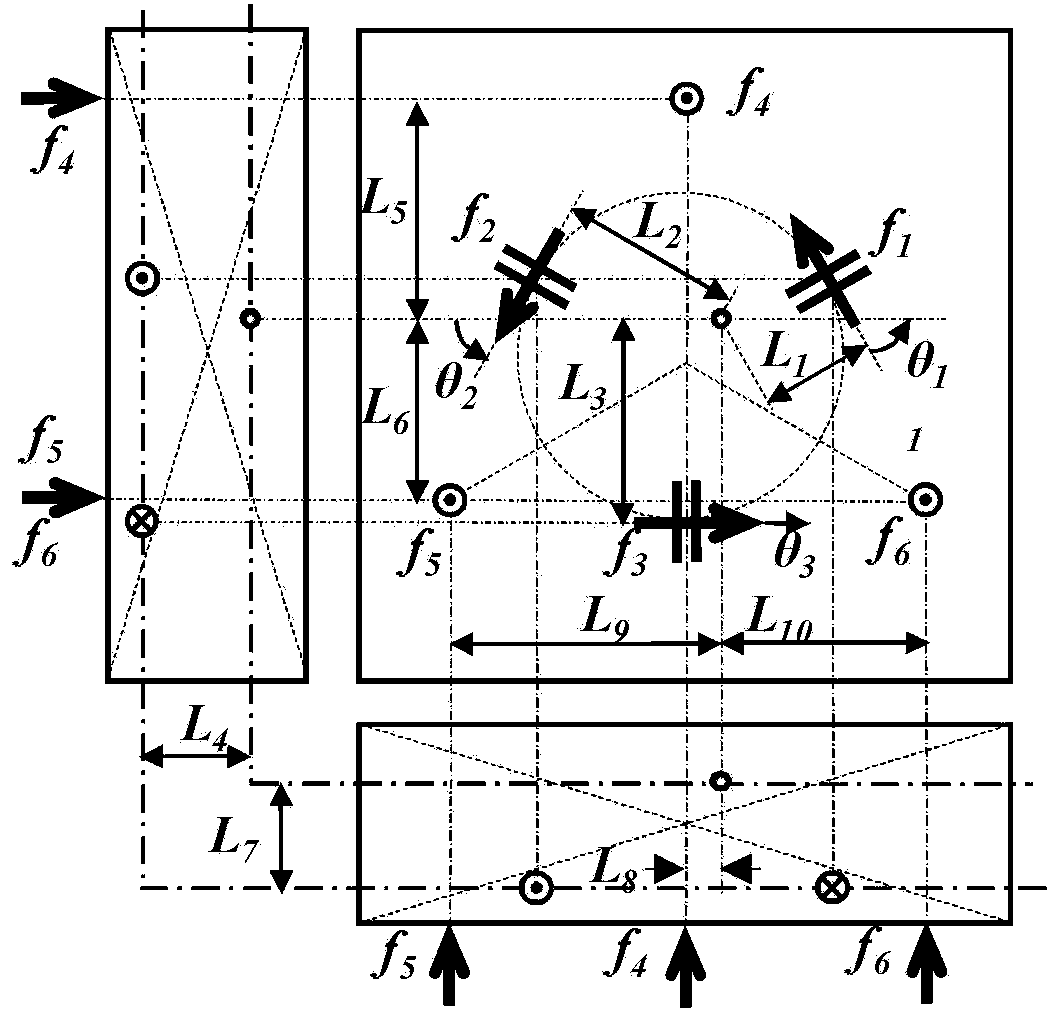

[0066]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the conversion relationship between the driving force and torque of the center of mass of the micro-movement part of the workpiece table and the driving force of the voice coil motor is specifically: F cog =L·f

[0067] where the matrix F cog =[F xcog f ycog T zcog f zcog T xcog T ycog ] T ,

[0068] f=[f 1 f 2 f 3 f 4 f 5 f 6 ] T ,

[0069] L = - cos θ 1 - cos θ 2 cos θ 3 0 0 ...

specific Embodiment approach 3

[0071] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 2, the positional relationship between the exposure center and the center of mass of the micro-movement part of the workpiece table is specifically:

[0072] x cog = x - ( y + y 0 ) r z + ( z + z 0 ) r y y cog ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com