Substrate adsorption device, photoetching equipment and adsorption method

A technology of adsorption device and substrate, which is applied in the direction of microlithography exposure equipment, photomechanical equipment, exposure device of photo-plate making process, etc., can solve the problem of lower reliability of silicon wafer, lower reliability of adsorption, affecting the exposure quality of silicon wafer and good quality of silicon wafer. Ratio and other issues, to achieve the effect of improving exposure quality and yield, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

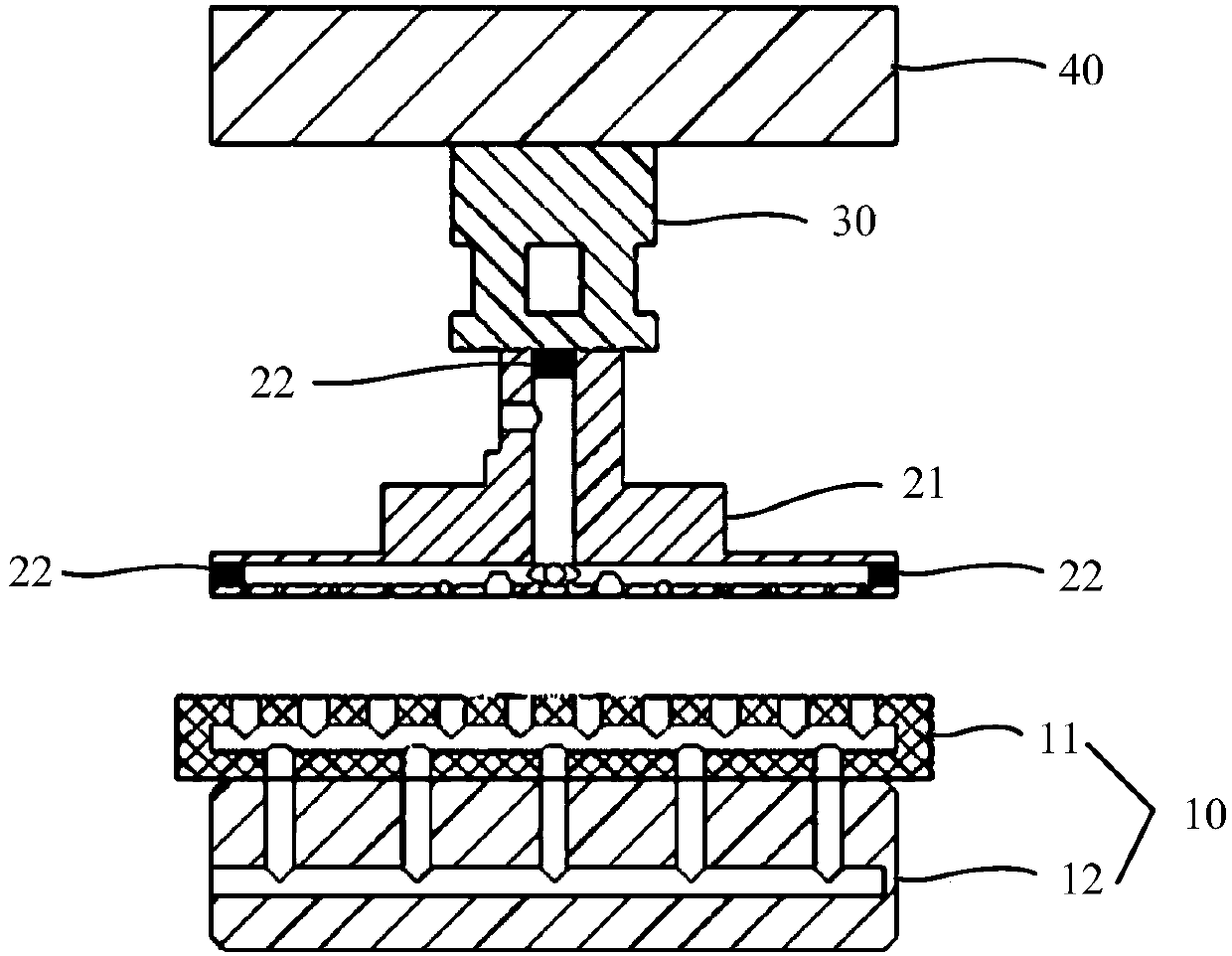

[0043] This embodiment provides a substrate adsorption device, figure 1 For the sectional view of the substrate adsorption device provided in Embodiment 1 of the present invention, refer to figure 1 , the substrate adsorption device includes an adsorption mechanism 10, and a shaping mechanism arranged opposite to the adsorption mechanism 10, and a substrate accommodation space is formed between the adsorption mechanism 10 and the shaping mechanism;

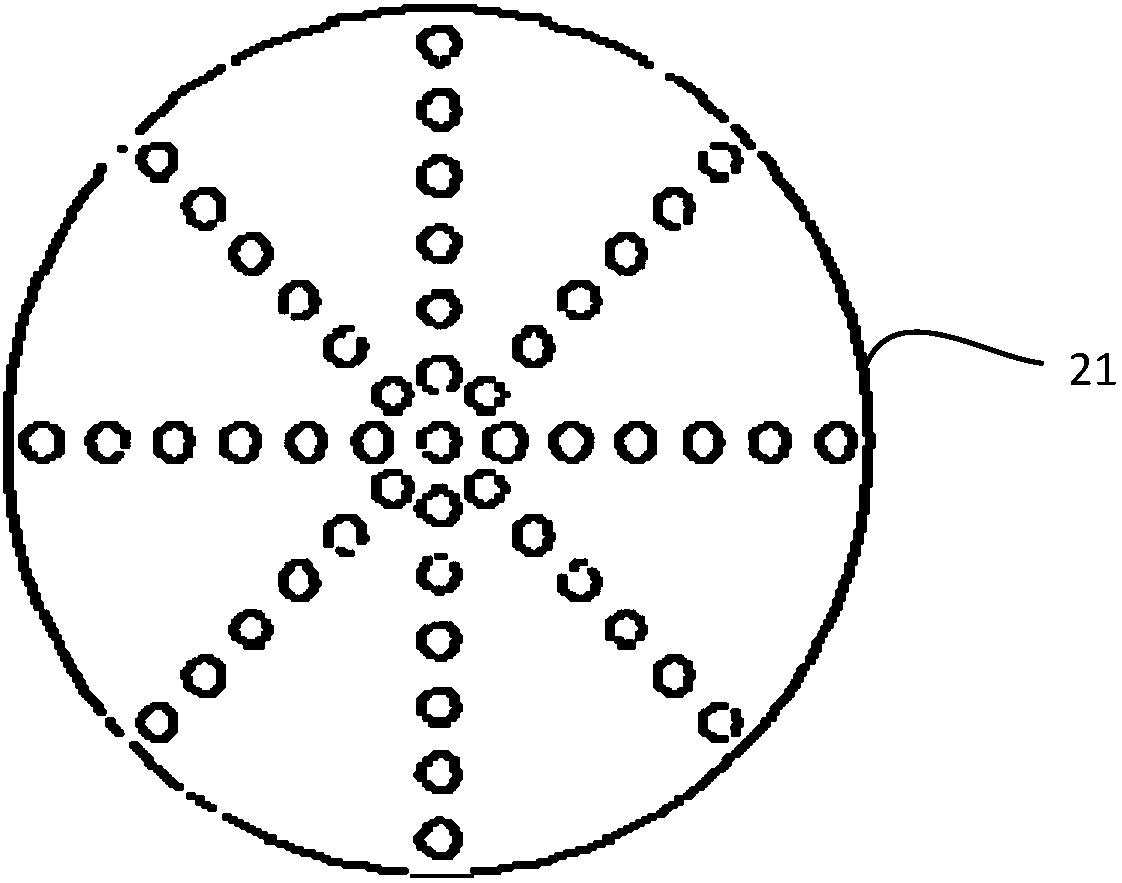

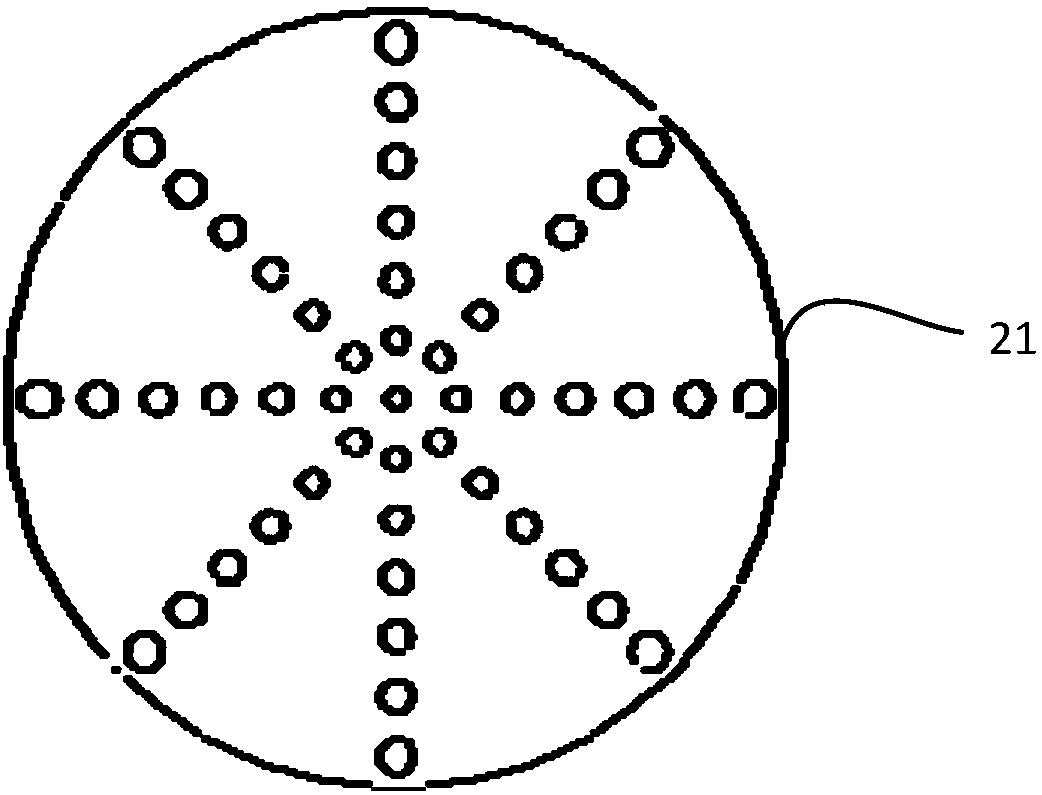

[0044] The adsorption mechanism 10 includes a suction cup 11, a plurality of suction holes are distributed on the surface of the suction cup 11, and the suction cup 11 is used to adsorb the substrate in the substrate accommodation space from the first side;

[0045] The shaping mechanism is used to act on the substrate in the substrate accommodating space from the second side opposite to the first side, so as to cooperate with the suction cup 11 to level the substrate in the substrate accommodating space.

[0046] Exemplarily, in...

Embodiment 2

[0063] This embodiment provides a lithographic equipment, the lithographic equipment includes the substrate adsorption device in the first embodiment, refer to figure 1 , the substrate adsorption device includes an adsorption mechanism 10, and a shaping mechanism arranged opposite to the adsorption mechanism 10, and a substrate accommodation space is formed between the adsorption mechanism 10 and the shaping mechanism;

[0064] The adsorption mechanism 10 includes a suction cup 11, a plurality of suction holes are distributed on the surface of the suction cup 11, and the suction cup 11 is used to adsorb the substrate in the substrate accommodation space from the first side;

[0065] The shaping mechanism is used to act on the substrate in the substrate accommodating space from the second side opposite to the first side, so as to cooperate with the suction cup 11 to level the substrate in the substrate accommodating space.

[0066] The lithography equipment provided by the embo...

Embodiment 3

[0068] This embodiment provides an adsorption method for a substrate adsorption device, wherein, refer to figure 1 , the substrate adsorption device includes an adsorption mechanism 10, and a shaping mechanism opposite to the adsorption mechanism, Figure 7 is the flowchart of the adsorption method, such as Figure 7 As shown, the adsorption method includes:

[0069] S11: the adsorption mechanism absorbs the substrate sheet from the first side of the substrate through the suction hole on the suction cup.

[0070] Specifically, after the substrate is transferred to the adsorption mechanism 10, the adsorption mechanism starts to evacuate, and through the suction holes on the surface of the suction cup 11, a vacuum is formed between the first side of the silicon wafer and the suction cup 11, thereby initially adsorbing the substrate on the suction cup. 11 on. Exemplarily, in this embodiment, the finite element simulation conditions are selected as follows: the substrate is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com