High-precision full-automatic double-side exposure machine

A double-sided exposure, fully automatic technology, applied in the field of exposure machines, can solve problems such as low efficiency, increased equipment size, and complicated working procedures, and achieves high alignment accuracy, preventing pattern misalignment, and improving exposure quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

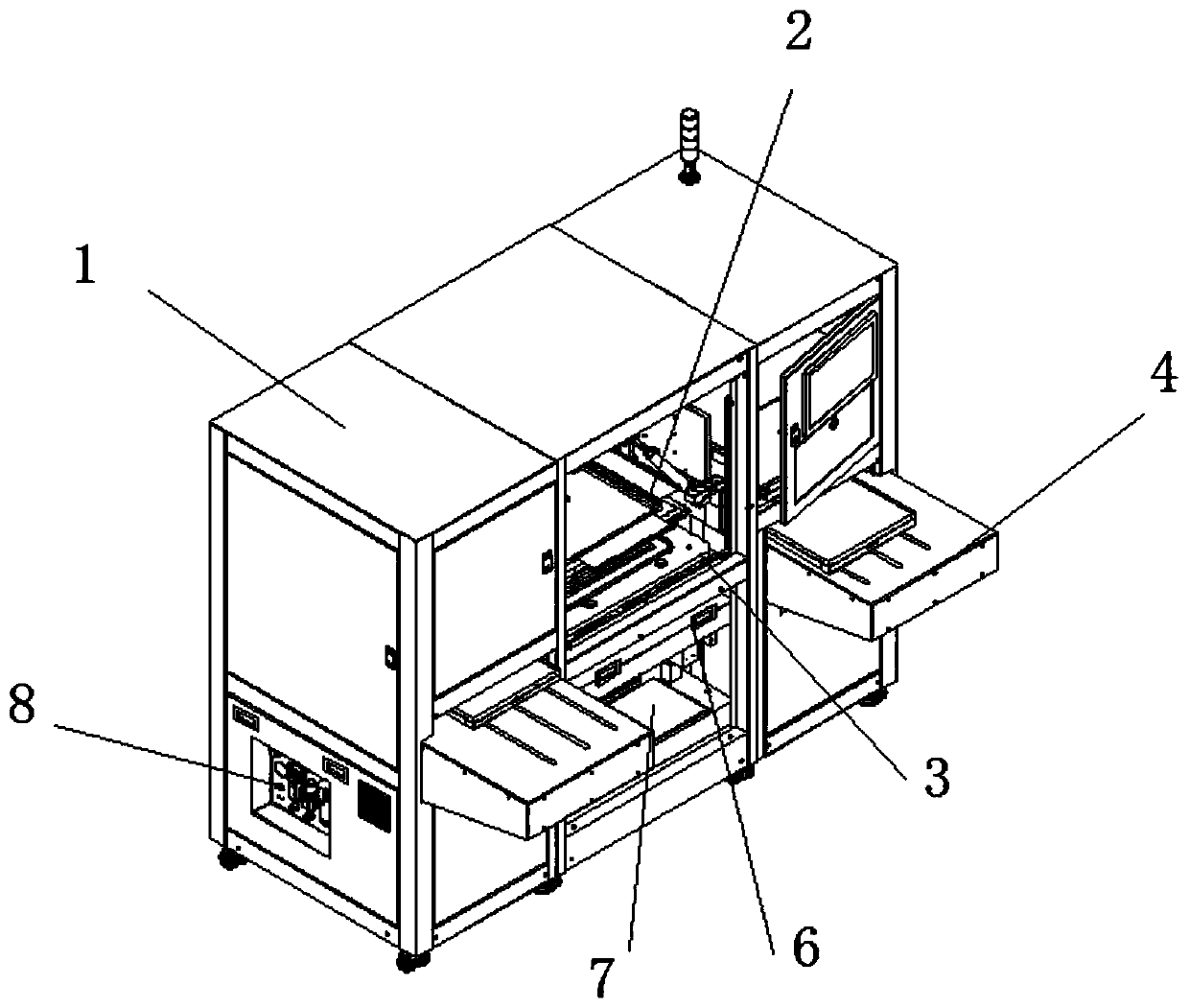

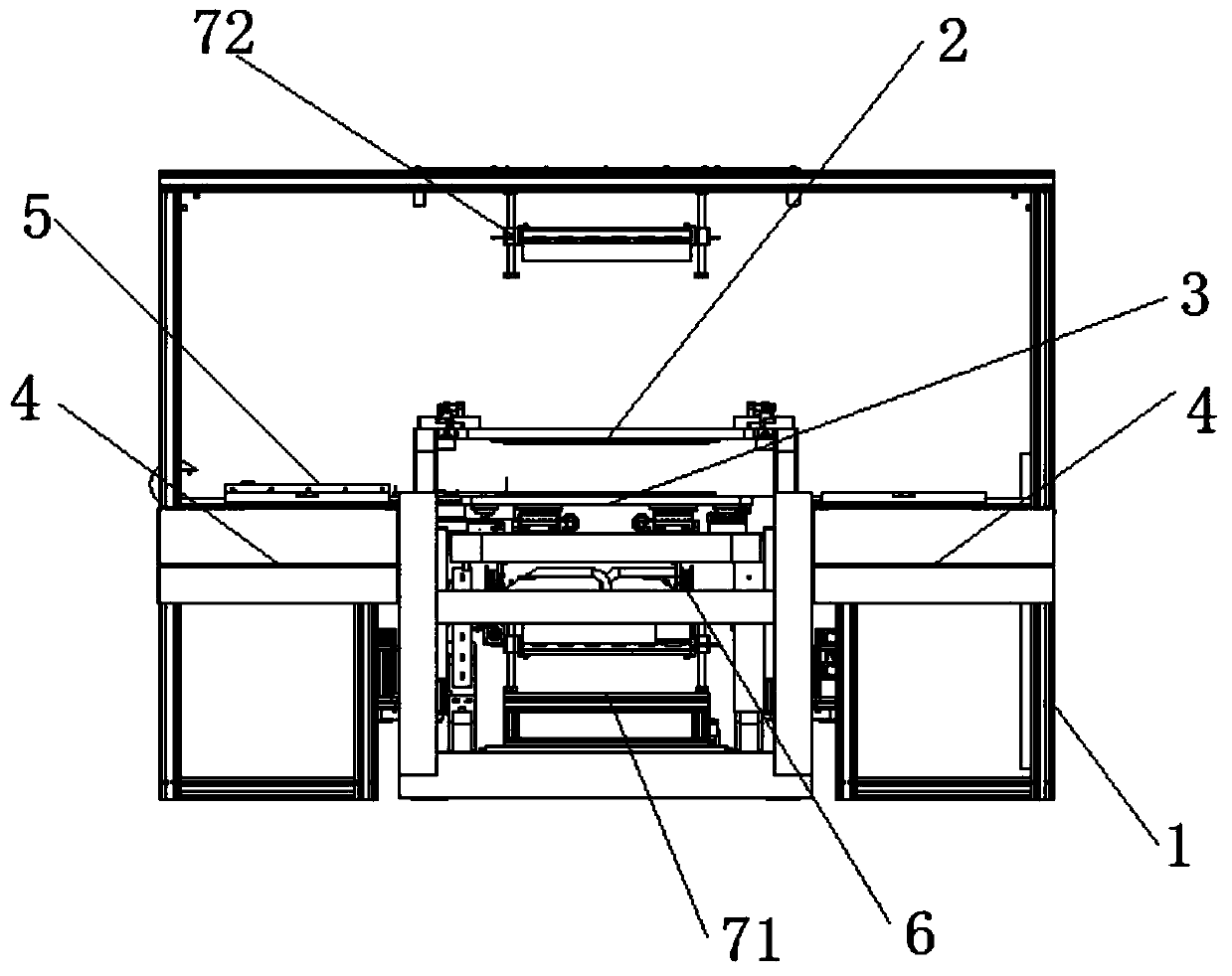

[0058] Such as figure 1 and figure 2 As shown, this embodiment relates to a high-precision fully automatic double-sided exposure machine, including a frame 1 for supporting and installing various modules and systems in the exposure machine;

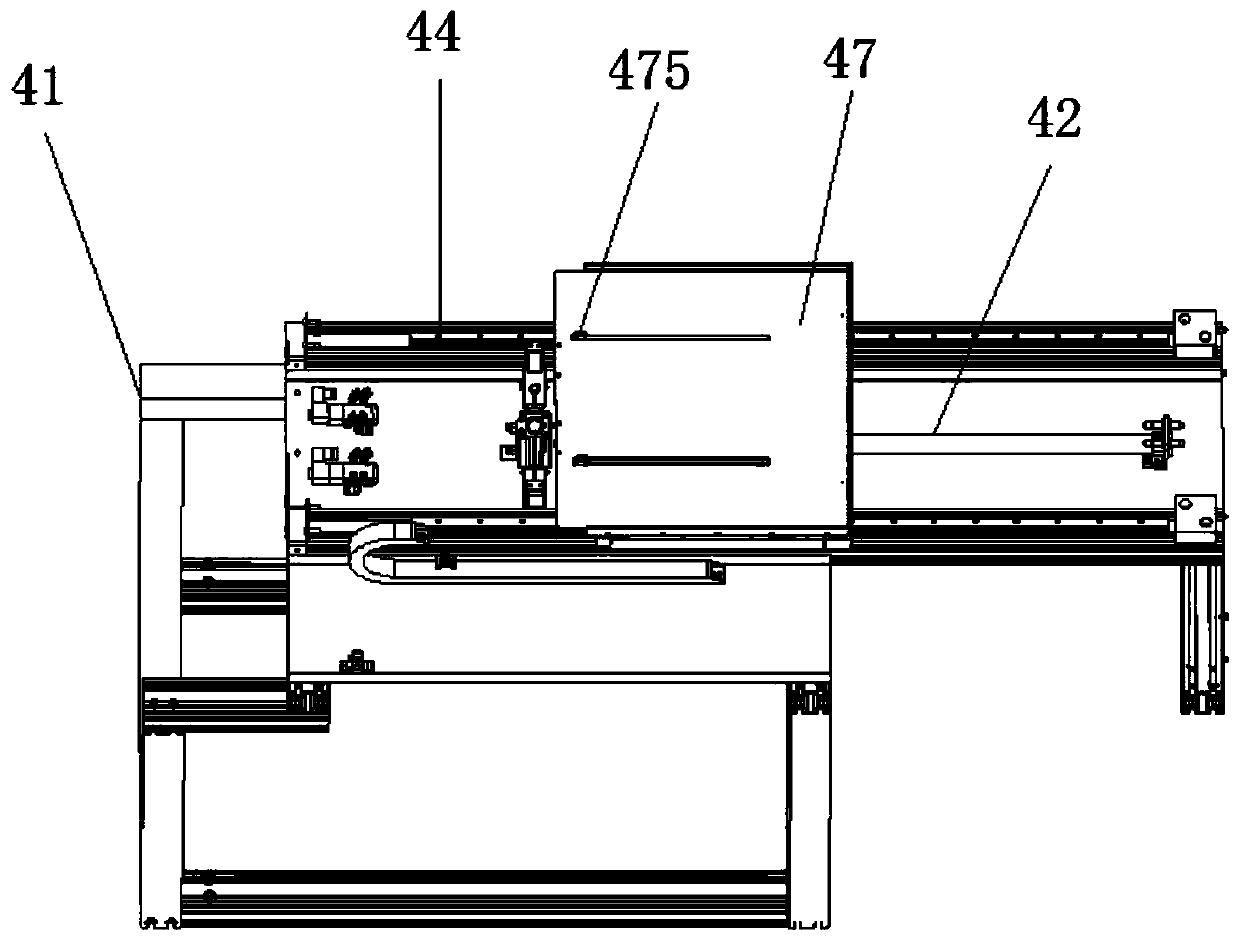

[0059] The upper frame system 2 is located inside the frame 1, including an upper mask plate 27 that provides patterns for exposure of the upper surface of the product;

[0060] The alignment system 3 includes a lower mask plate 313 that provides a pattern for the exposure of the lower surface of the product, and is used to achieve precise alignment of the upper mask plate 27 and the lower mask plate 313. The alignment system 3 is located on the upper fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com