Mask plate, fabrication method thereof and exposure system

A mask plate and mask technology, which is applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of source-drain channel disconnection, thin resist, and thin-film transistor inoperability, etc. Achieve the effect of improving exposure quality and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

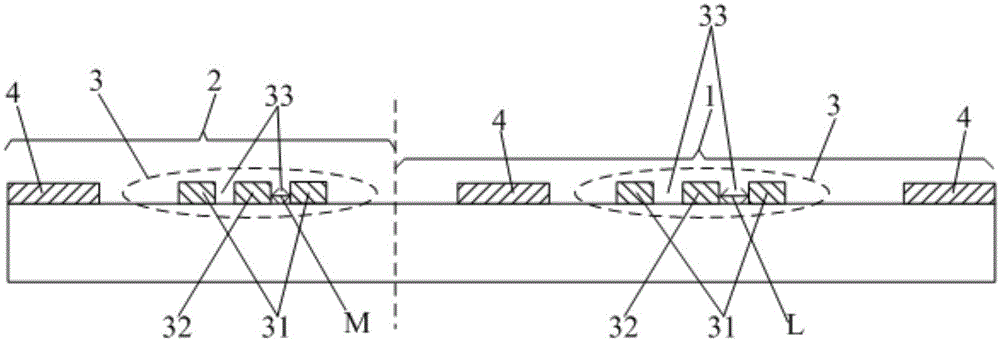

[0037] This embodiment provides a mask, such as figure 2 As shown, it includes a transparent substrate (not marked) and a mask pattern formed on the surface of the transparent substrate.

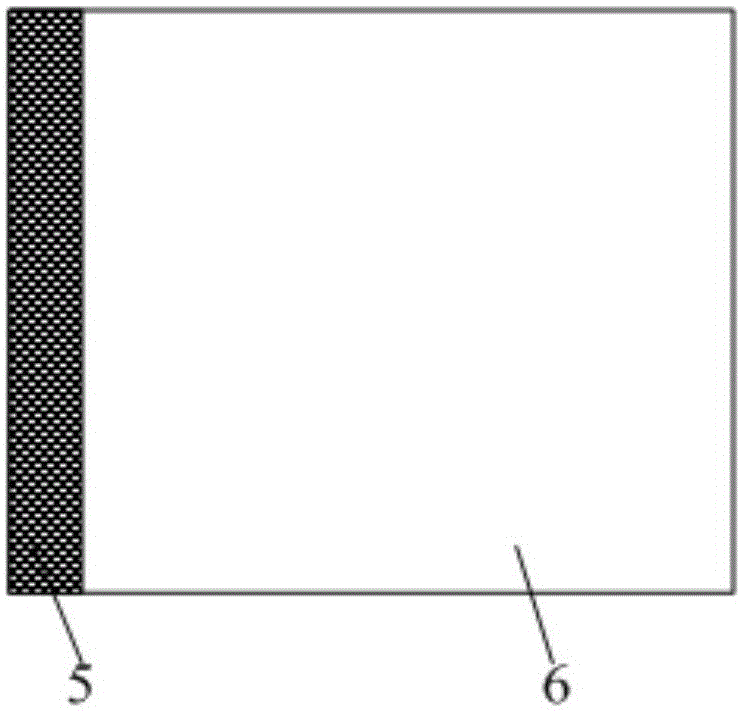

[0038] Wherein, the mask pattern includes a first area 1 for correspondingly forming the film layer pattern in the display area and a second area 2 for correspondingly forming the film layer pattern in the non-display area;

[0039] Both the first area 1 and the second area 2 are provided with a plurality of patterned masks 3, and the distribution density of the patterned masks 3 in the first area 1 is smaller than the distribution density of the patterned masks 3 in the second area 2;

[0040] Each patterned mask 3 includes a first pattern 31 for forming the source of the transistor, a second pattern 32 for forming the drain of the transistor, and a pattern interposed between the first pattern 31 and the second pattern 32. The slit 33; the width L of the slit 33 in the first zone 1 is gre...

Embodiment 2

[0060] This embodiment provides an exposure system, including the mask plate in Embodiment 1.

[0061] By using the mask plate in embodiment 1, the exposure quality of the exposure system is improved, thereby improving the quality of products exposed by the exposure system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com