Tool and method for detecting tiny bubbles in immersion flow field of immersion lithography machine

A technology for detecting tooling and lithography machines, which is used in measurement devices, optomechanical equipment, microlithography exposure equipment, etc., and can solve the problems of micro-bubble detection devices that cannot obtain global images at the same time, detect bubble loss, and exposure defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

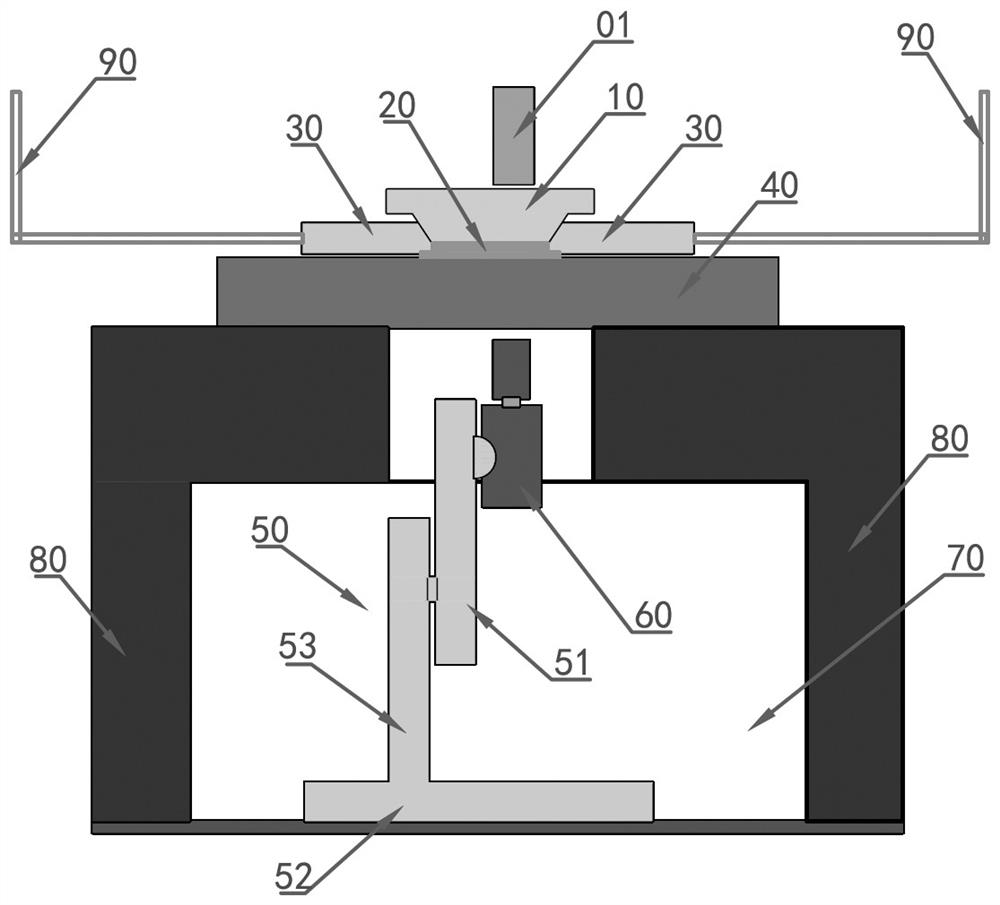

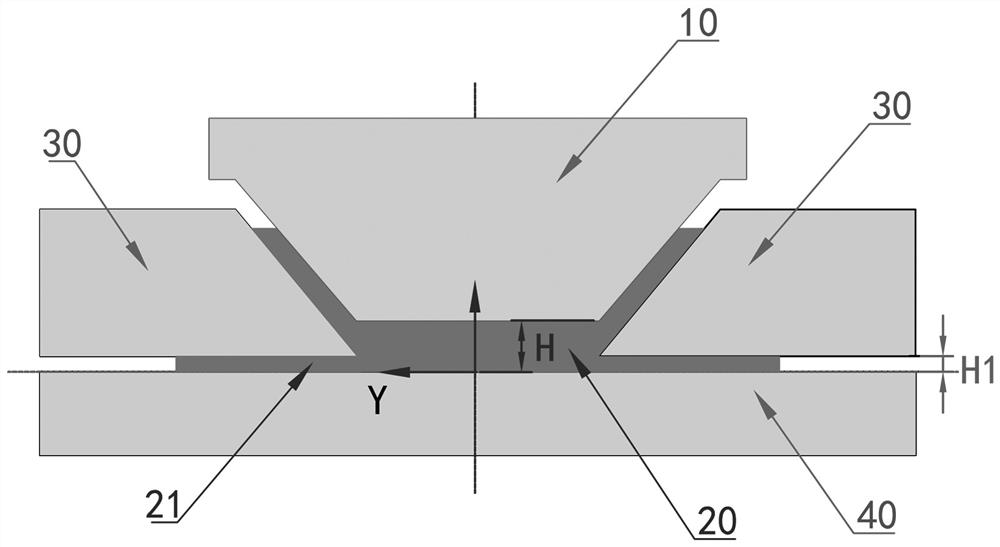

[0038] figure 1 , image 3 In the shown embodiment, an immersion lithography machine immersion microbubble detection tool in the immersion flow field includes an immersion flow field maintenance system with an immersion head 30, a simulated objective lens 10 and a simulated silicon wafer 40, and also includes a camera system 60 and The camera pose adjustment system 50, the shooting system 60 includes a shooting camera, a camera lens and a shooting light source 01; the camera pose adjustment system 50 is used to adjust the shooting camera along the X axis, the Y axis or the Z axis (see image 3) in the direction of motion adjustment, where the Z axis is used to realize the focusing and layered scanning movement of the shooting camera, the X axis and the Y axis; the immersion flow field is located on the XY plane formed by the X axis and the Y axis, and its position is constant ; When detecting bubbles, gradually move the camera and take pictures on the XY plane, so that the cap...

Embodiment 2

[0040] figure 2 , Figure 4 In the shown embodiment, a method for detecting micro-bubbles in an immersion lithography machine in an immersion flow field includes the following detection steps

[0041] A1 Fix the immersion head, the simulated objective lens and the test sample to be detected on the micro-bubble detection tooling in the immersion flow field of the immersion lithography machine described in the technical solution of embodiment 1;

[0042] A2 Install the micro-bubble detection tooling in the immersion flow field of the immersion lithography machine, the test sample to be detected, the immersion head and the simulated objective lens on the workpiece table in sequence;

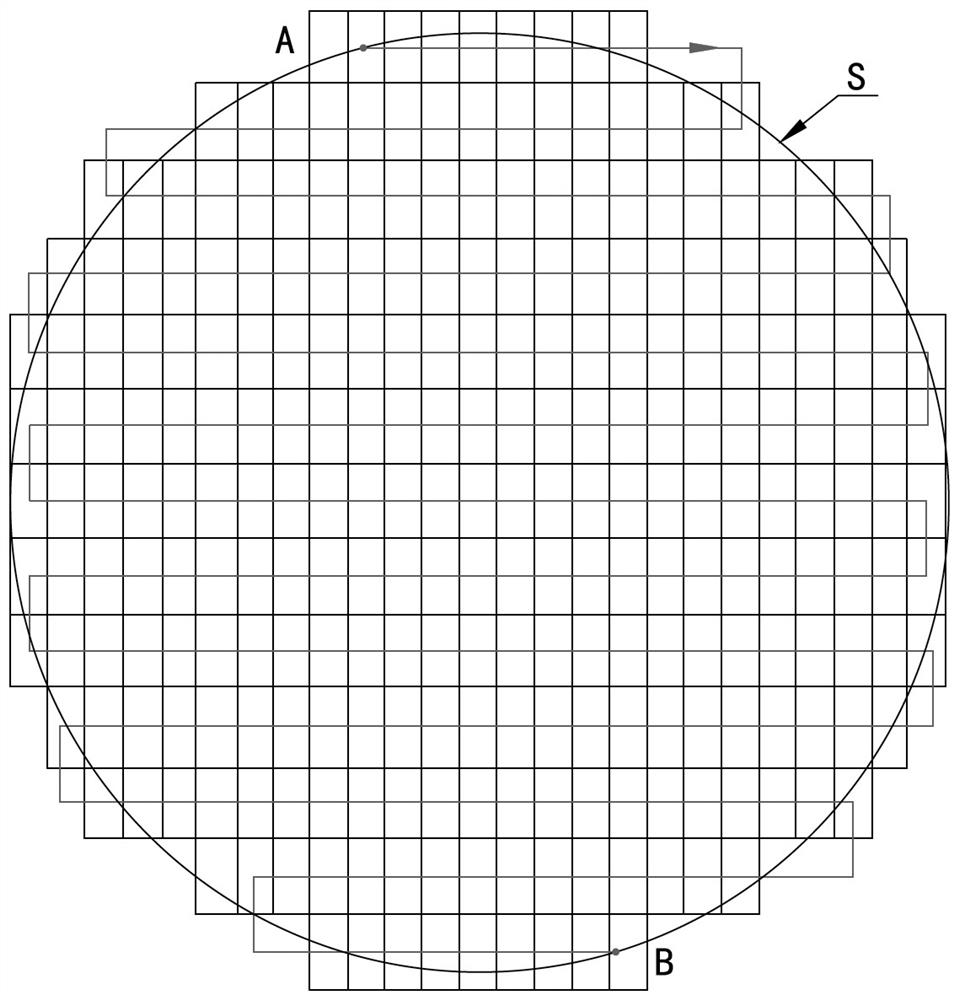

[0043] A3 Install the shooting camera to the corresponding adjustment position of the camera pose adjustment system, use the camera pose adjustment system to focus on the flow field where the immersion flow field is close to the upper layer of the simulated objective lens, and set an appropriate l...

Embodiment 3

[0057] figure 2 , Figure 4 In the shown embodiment, in the B5 detection step of Embodiment 2, the detection method adopted is that the photographing camera first does not move at one position, and drives the movement of the silicon wafer according to the movement mode of the silicon wafer under the scanning condition of the lithography machine. , that is, to simulate the exposure movement, use the shooting camera to monitor the air bubbles during the simulated exposure movement; after completing the monitoring of a site, move to the next small area in the submerged flow field to repeat the monitoring process of the simulated exposure movement, and so on until monitoring Small areas cover the entire submerged flow field. Others are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com