Ultraviolet light exposure system capable of emitting light in parallel and exposure machine

An exposure system and exposure machine technology, applied in the field of ultraviolet exposure, can solve problems such as unfavorable manufacturing process, environmental damage, and harmfulness to the operator, and achieve the effects of improving stability, avoiding expansion and contraction deformation, and good parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

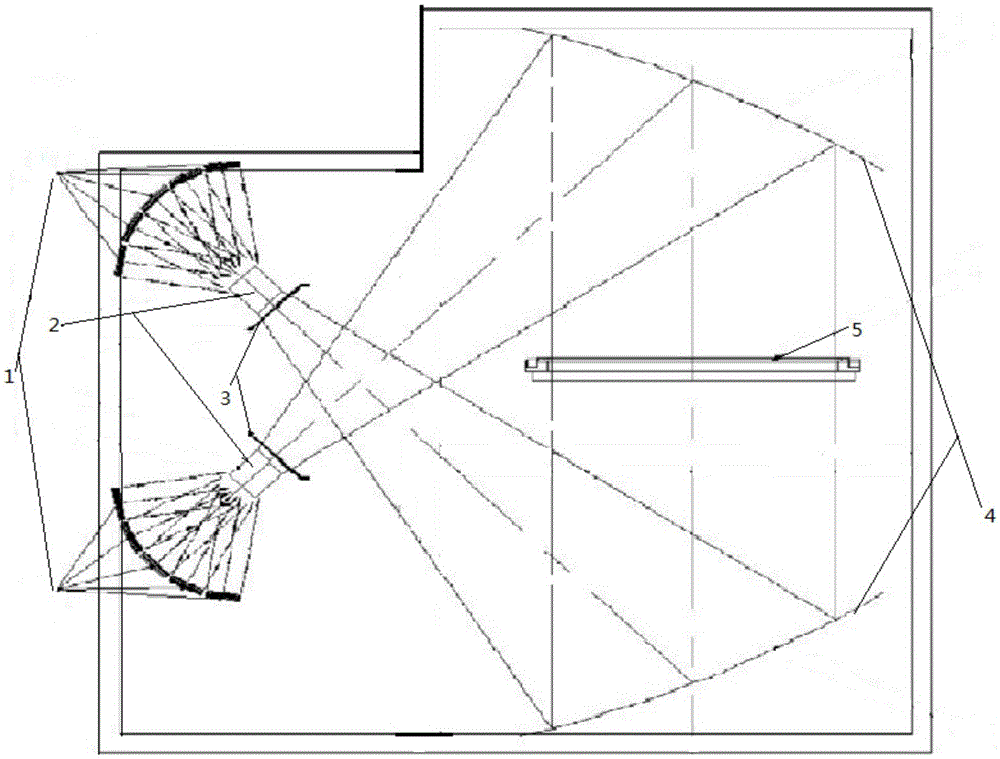

[0034] Example 1: Please also refer to figure 1, the parallel emission ultraviolet exposure system provided in this embodiment, which includes: a light source assembly 1 for providing a UV-LED light source and emitting ultraviolet light; a concentrator 2 for receiving and converging ultraviolet light; a shutter 3 for Control the exposure time and exposure amount; the curved mirror 4 is used to reflect the received ultraviolet light and then parallel incident it to the surface of the exposure table 5 for exposure. The light source assembly 1 includes a plurality of UV-LED light sources, and the plurality of UV light -LED light source, all illuminated to the concentrator and focused to project energy onto the concentrator. The light source assembly 1 is preferably five UV-LED light sources arranged one by one to form a concave surface. In addition, the number of UV-LED light sources can also be less than five or more than five, but can be arranged to form a concave mirror shape...

Embodiment 2

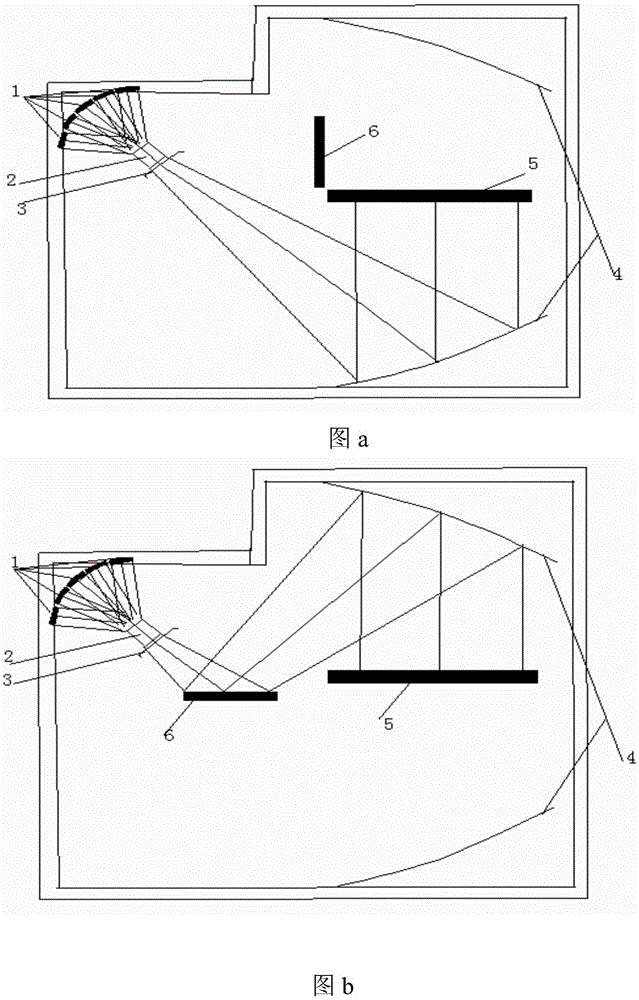

[0042] Example 2: Please also refer to figure 2 , the parallel light emitting ultraviolet exposure system provided in this embodiment is basically the same as that of Embodiment 1, the difference is that the parallel light emitting ultraviolet exposure system adopts a single light source assembly, and also includes a flip mirror 6, and the flip mirror 6 is arranged on the shutter 2 and the exposure table 5; the flip mirror 6 is used to expose the upper and lower surfaces of the exposure table 5 under the condition of a single light source, and the flip mirror 6 is parallel or perpendicular to the exposure table 5 in different states: when the flip mirror When it is arranged parallel to the exposure table 5 (Fig. b), the light is reflected and then incident on the curved mirror located above, and then irradiated parallel to the upper surface of the exposure table for exposure. When the flip mirror and the exposure table 5 are arranged perpendicular to each other (Fig. a) The l...

Embodiment 3

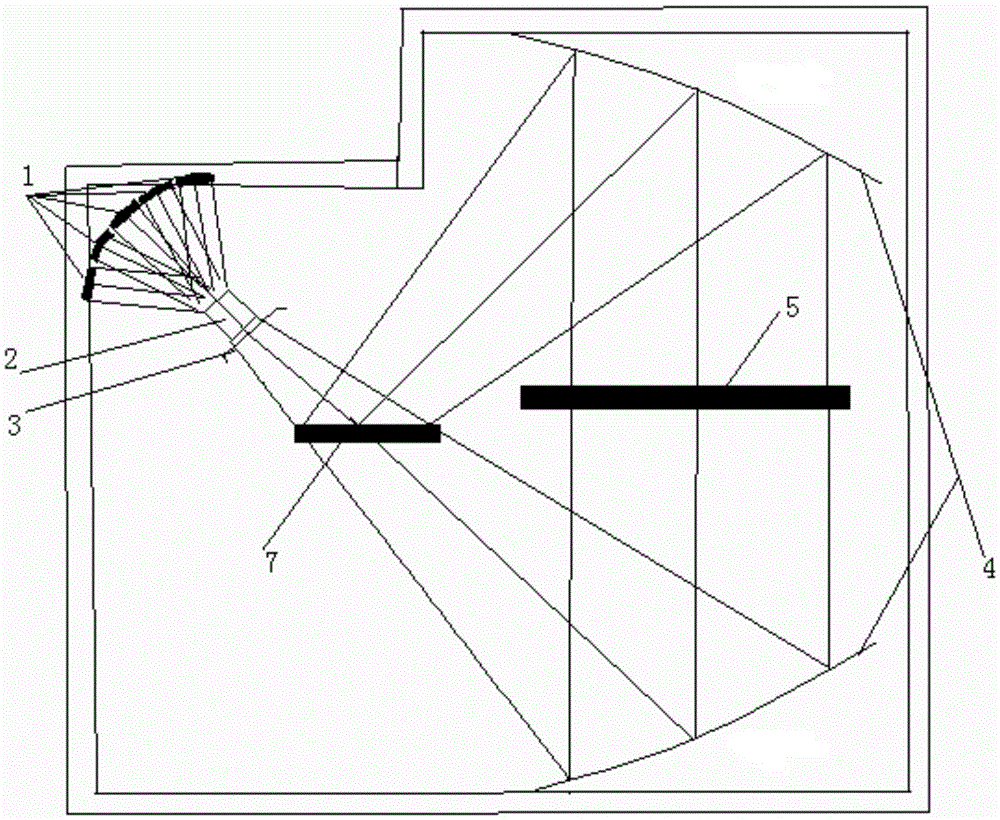

[0044] Example 3: Please also refer to image 3 , the parallel light emitting ultraviolet exposure system provided in this embodiment is basically the same as that of Embodiment 1, the difference is that the parallel light emitting ultraviolet exposure system adopts a single light source assembly and also includes a beam splitter 7, and the beam splitter 7 is set Between the shutter 2 and the exposure stage 5; the beam splitter 7 is used to expose the upper and lower surfaces of the exposure stage 5 under the condition of a single light source, and the beam splitter 7 can realize 50% of the incident light on the beam splitter The light is reflected to the curved mirror at the top and then irradiated parallel to the upper surface of the exposure table for exposure, and at the same time, the other 50% of the light incident on the beam splitter is incident to the curved mirror at the bottom and then irradiated parallel to the lower surface of the exposure table The surface is exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com