X-ray detector and charge emptying method

An X-ray and detector technology, applied in the field of detectors, can solve the problems of complicated emptying process, exposure conflict, long time consumption, etc., to simplify the exposure process, suppress the generation of interference charges, and speed up the exposure response ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

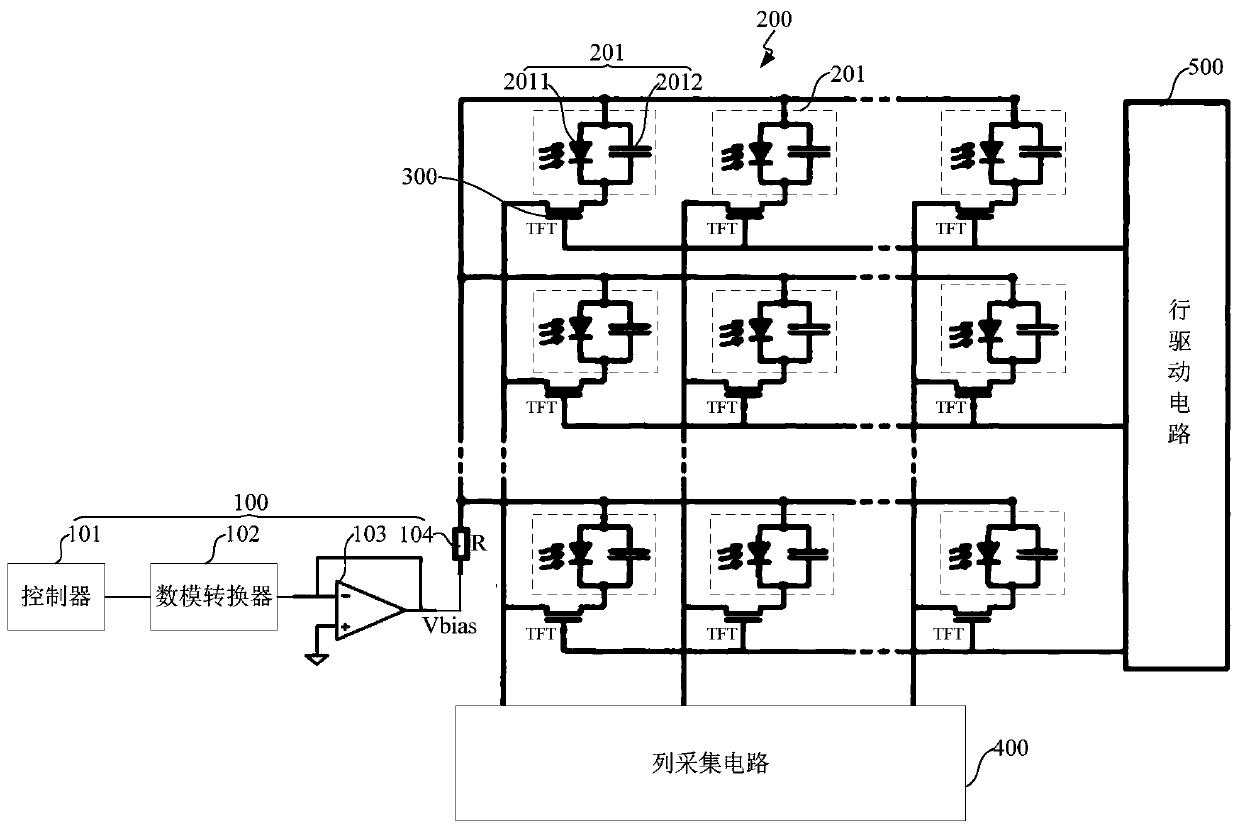

[0042] Such as figure 1 As shown, the present embodiment provides an X-ray detector, and the X-ray detector includes:

[0043] A bias voltage dynamic adjustment unit 100, configured to provide a negative bias voltage when the X-ray detector is in an exposure state; provide a forward bias voltage when the X-ray detector is in an idle state;

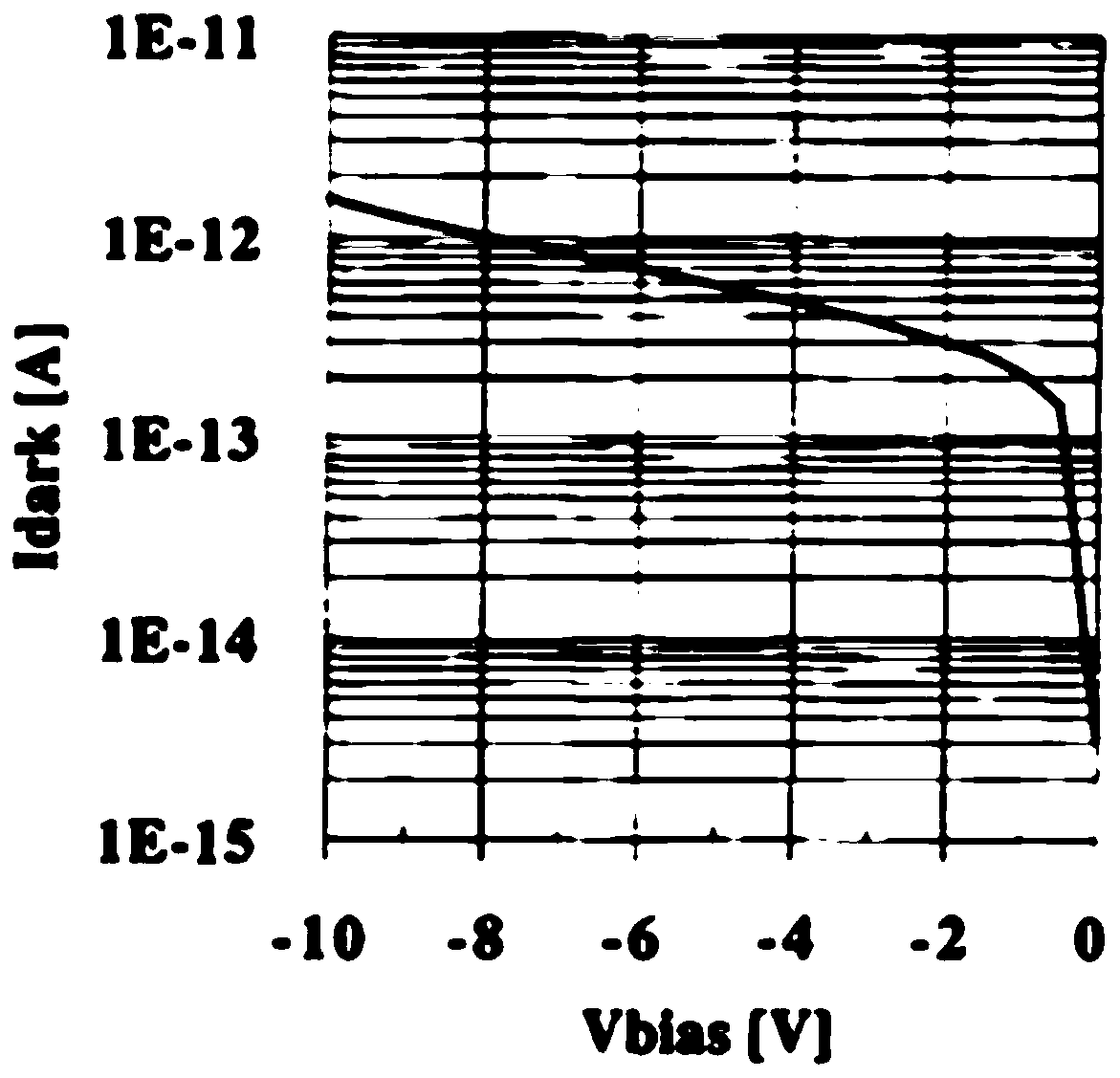

[0044] The photodetection unit 200 includes several photodetectors 201 arranged in an array, and each photodetector 201 is connected in parallel to the bias voltage dynamic adjustment unit 100, wherein the photodetector 201 includes a photodiode 2011 and a parallel connection The capacitor 2012 at both ends of the photodiode 2011; under the control of the negative bias voltage, the photodiode 2011 is in the reverse amplification region to realize photoelectric conversion; under the control of the forward bias voltage , so that the photodiode 2011 is in the forward blocking region to reduce its dark current.

[0045] This embodiment utili...

Embodiment 2

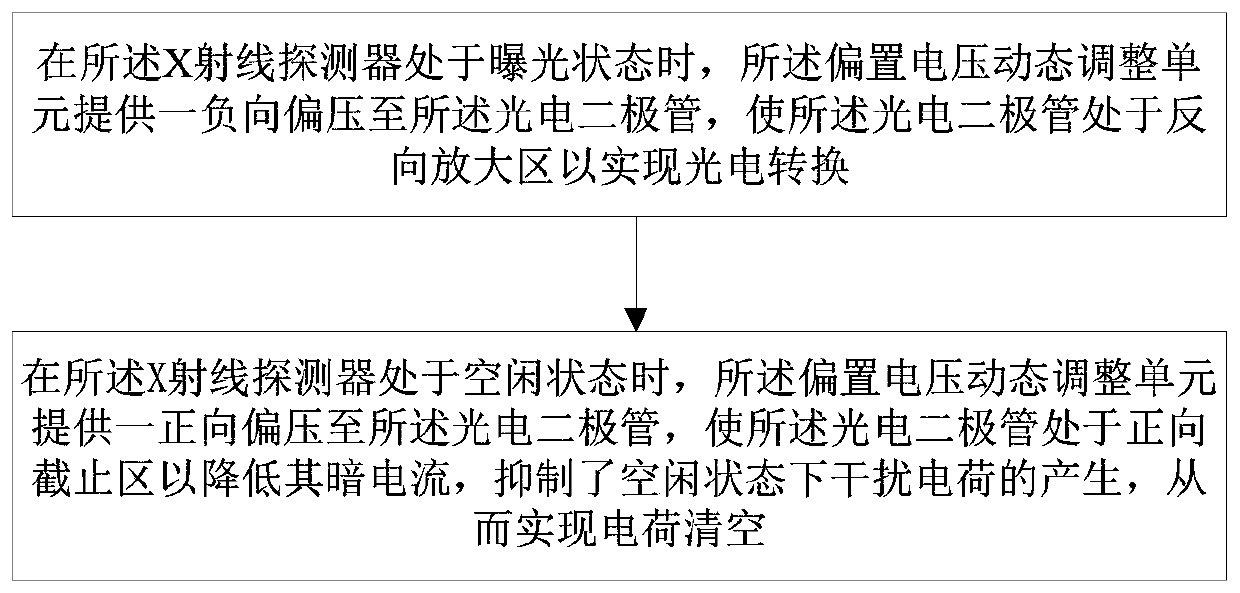

[0056] Such as image 3 As shown, this embodiment provides a charge clearing method implemented by using the X-ray detector described in Embodiment 1. The charge clearing method includes:

[0057] When the X-ray detector is in the exposure state, the bias voltage dynamic adjustment unit provides a negative bias voltage to the photodiode, so that the photodiode is in a reverse amplification region to realize photoelectric conversion;

[0058] When the X-ray detector is in an idle state, the bias voltage dynamic adjustment unit provides a forward bias voltage to the photodiode, so that the photodiode is in the forward cut-off region to reduce its dark current, suppressing In the idle state, the generation of interference charge is disturbed, so as to realize the charge emptying.

[0059] As an example, the method for realizing the dynamic adjustment of the bias voltage includes: detecting the state of the X-ray detector, and if the X-ray detector is in the exposure state, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com