Prism glass cutting machine

A prism glass and cutting machine technology, applied in glass cutting devices, glass manufacturing equipment, metal processing, etc., can solve problems such as affecting the quality of finished products, inability to adjust, and processing limitations of prism glass, improving accuracy and preventing glass from shifting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

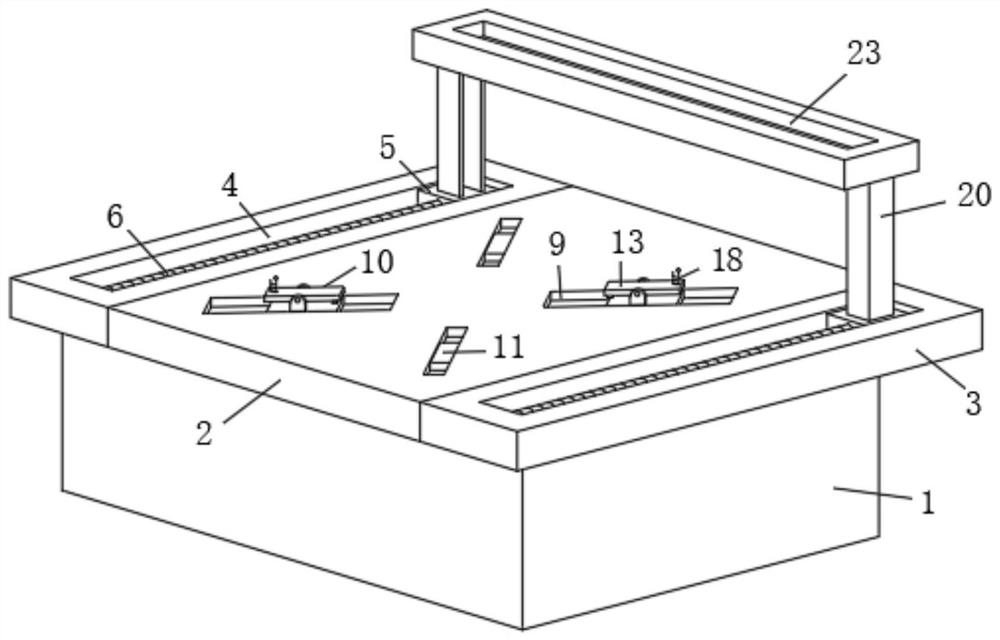

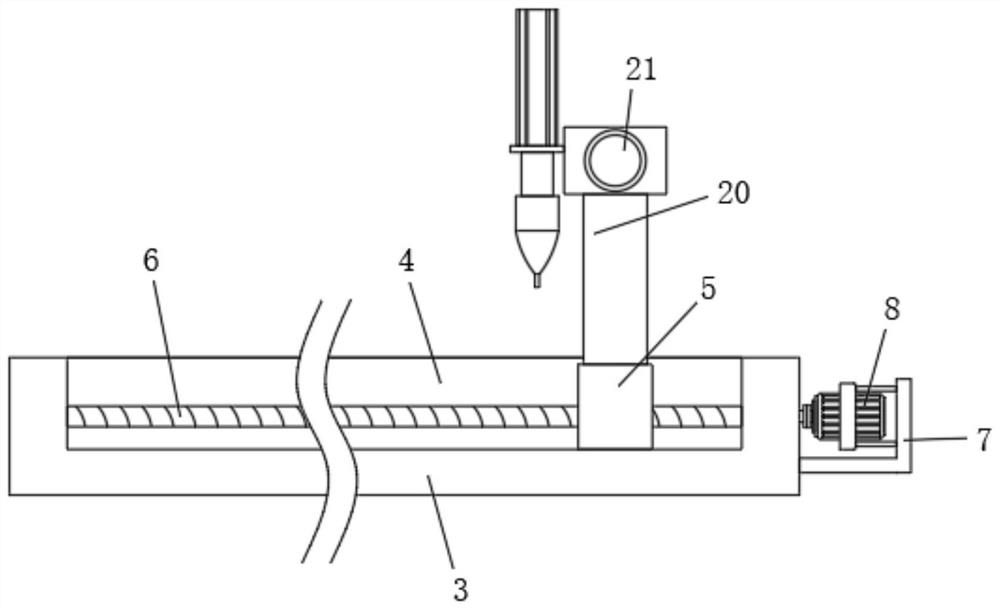

[0024] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a prism glass cutting machine, including an equipment base 1, the top of the equipment base 1 is fixedly connected with a placement plate 2, and the top of the placement plate 2 is excavated with four No. 2 chute 9, the inside of the No. 2 chute 9 is provided with a clamping mechanism 10, both sides of the placement plate 2 are fixedly connected with slideways 3, and the tops of the two slideways 3 are excavated No. 1 chute 4 is provided, and a No. 1 slide block 5 is slidably connected to the inside of the two No. 1 chute 4s, and a connection frame 20 is connected to the tops of the two No. 1 slide blocks 5, and the connection frame 20 The bottoms of both ends are respectively fixedly connected with the two No. 1 sliders 5 , and the top of the connection frame 20 is excavated with a No. 3 chute 23 .

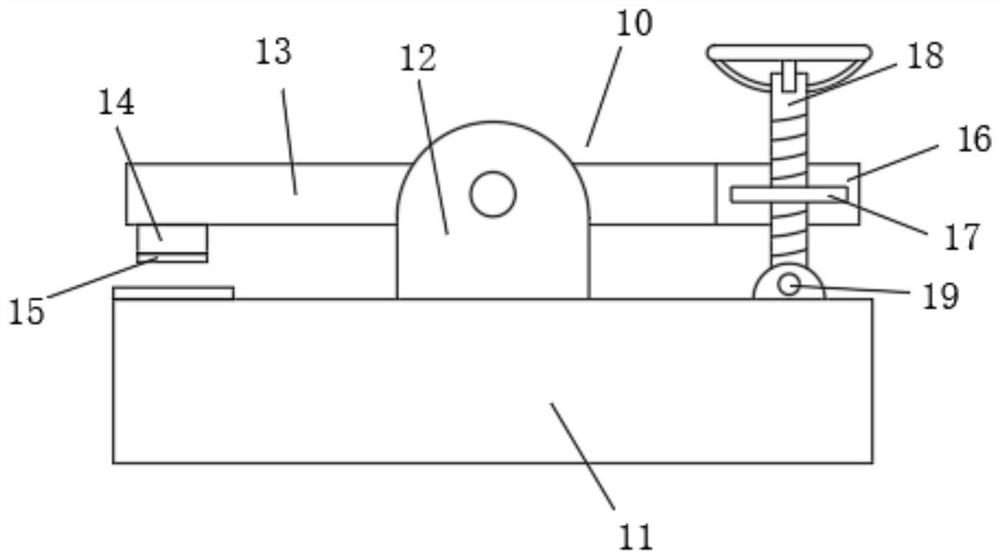

[0025] Wherein, the clamping mechanism 10 includes a No. 2 slider 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com