Thermal precise forming method and device for toothed steering rocker arm shaft

A steering rocker arm and precision forming technology, which is applied in forging/pressing/hammer devices, manufacturing tools, swaging presses, etc., to achieve the effects of simple process, saving mold materials and processing costs, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

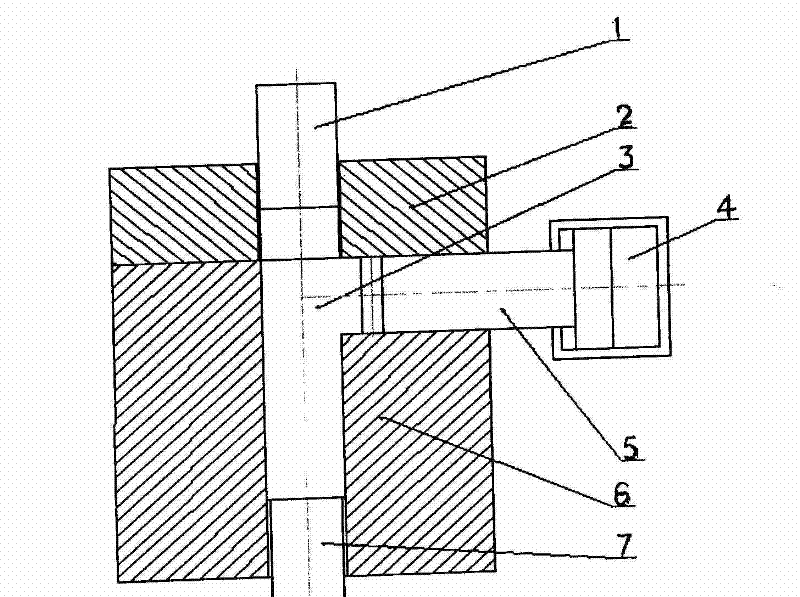

[0018] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

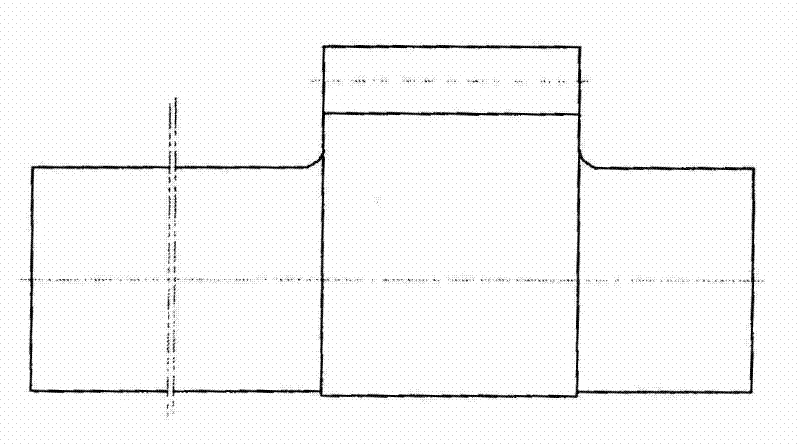

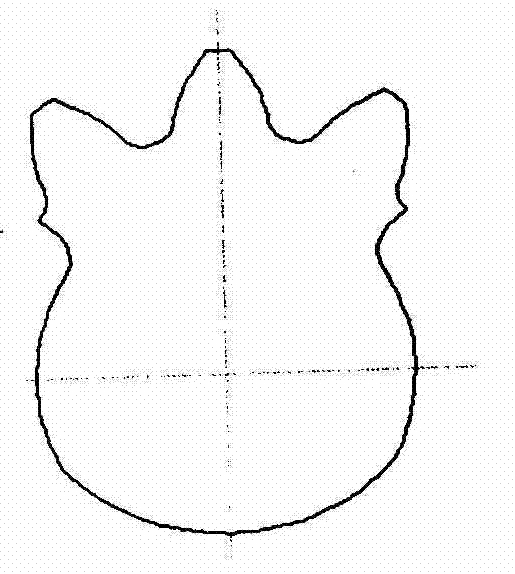

[0019] Such as image 3 As shown, the device of the present invention includes a toothed rocker shaft molding die that is composed of a die 6 and an extrusion sleeve 2 that is buckled above the die 6 and is provided with a vertically connected die cavity and a side fan-shaped die cavity. And the punch 1 that is installed in the vertically connected mold cavity by the hydraulic press slide block for vertical displacement movement from top to bottom, and the ejector rod 7 that is installed in the vertically connected mold cavity from bottom to top. The tooth-shaped punch 5 that is installed in the side-mounted fan-shaped die cavity is driven by the side-mounted hydraulic cylinder 4 for horizontal displacement.

[0020] The tooth-shaped steering rocker shaft thermal precision forming method of the present invention adopts the forming method of main direction (up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com