Process and die for stamping girdle-free conical spheres

A cone-shaped, crafted technology, used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of insufficient material density, damage, large impact force and deformation, etc., and achieve the failure rate of machine tools. The effect of reducing, reducing equipment failure rate and increasing tissue density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Select a steel wire with a material diameter of 9.0, pass the steel wire through the entrance of the light drawing machine, and perform horizontal light drawing to make the material transversely deformed and increase the tissue density of the material before the cutting pier is pressed; the steel wire that has been lightly drawn will enter the feeding mechanism , the cutting length is determined and cut during the feeding process; the cut steel wire section is sent to the center of the tapered cavity of the mold through the clamp, and the mold is closed, and the steel is pressed by the mold through the punching force of the machine tool itself. Compressed into a ball shape to complete the whole process of punching the ball.

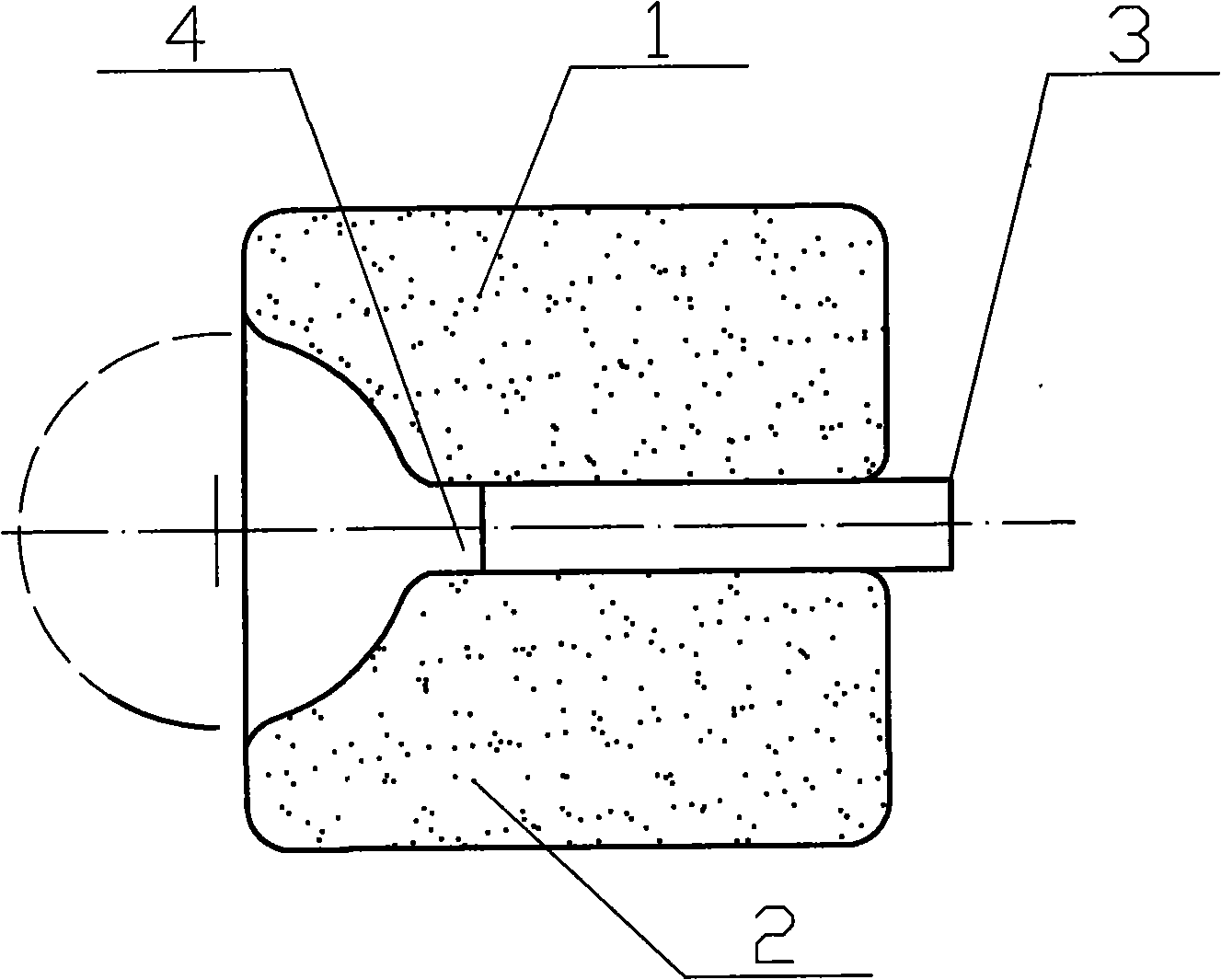

[0015] As shown in the figure, in this process, in order to make a sphere without annulus tapered, the present invention has used a kind of 90~120 ° conical mold, and this mold is made of two semi-bearing steel mold bases 1, 2 Composition, the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com