Prefabricated type pipe joint of comprehensive pipe gallery

A prefabricated assembly and comprehensive pipe gallery technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of low installation efficiency, long construction period, and many construction procedures, so as to improve installation efficiency and reduce construction costs , Reduce the effect of on-site installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

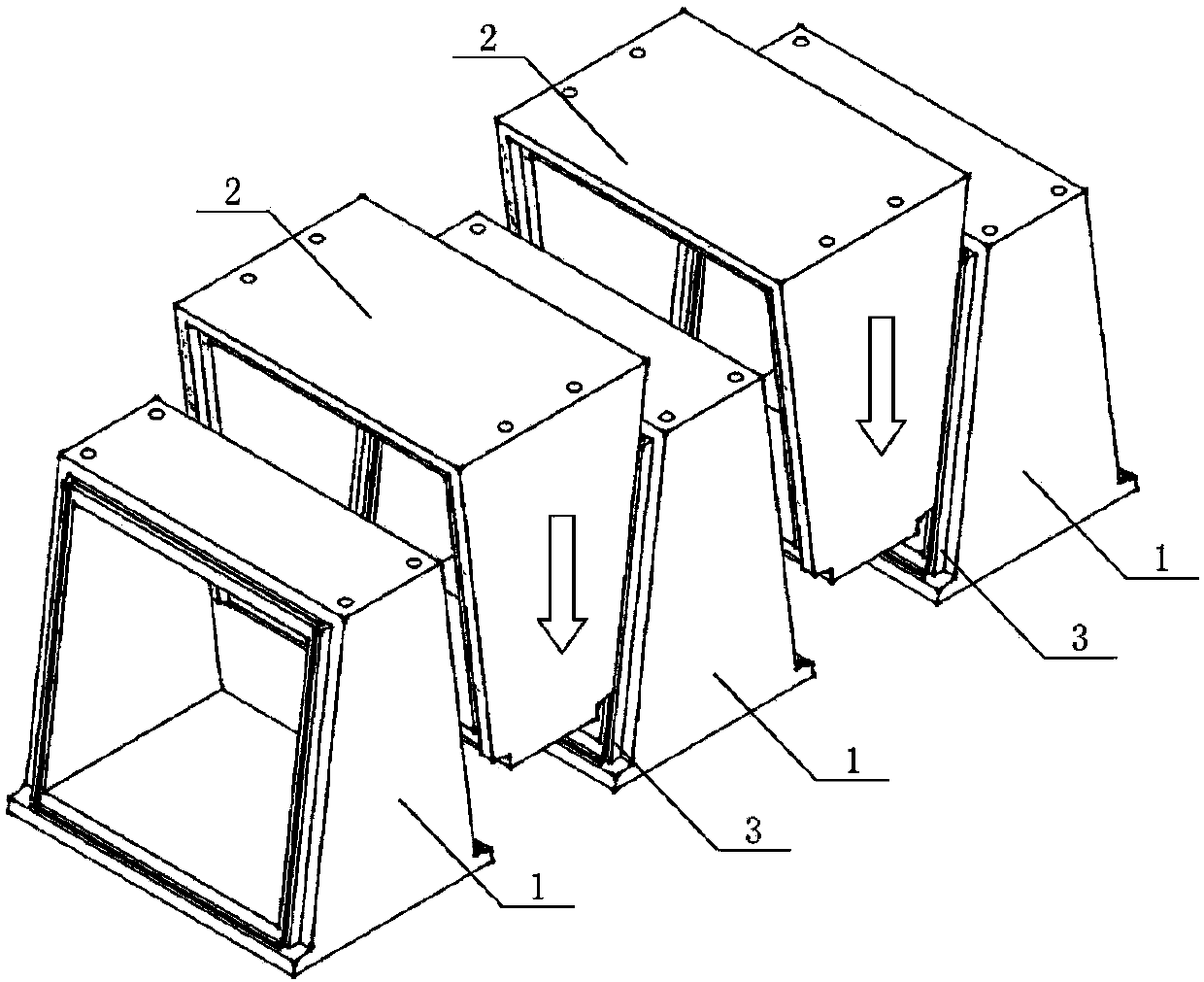

[0015] like figure 1 Shown: A prefabricated pipe joint of a comprehensive pipe gallery, which is composed of a regular trapezoidal segment structure and an inverted trapezoidal segment structure.

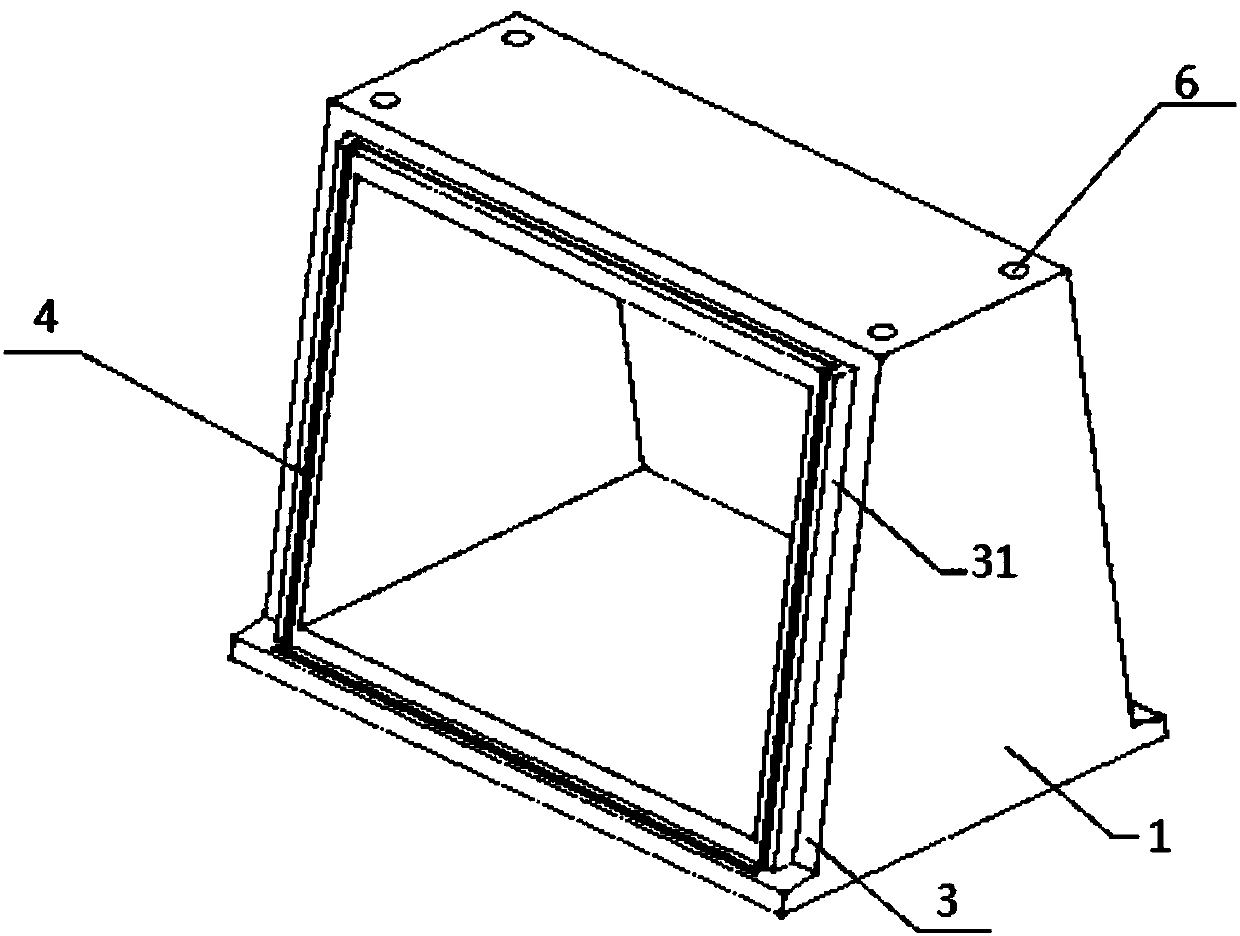

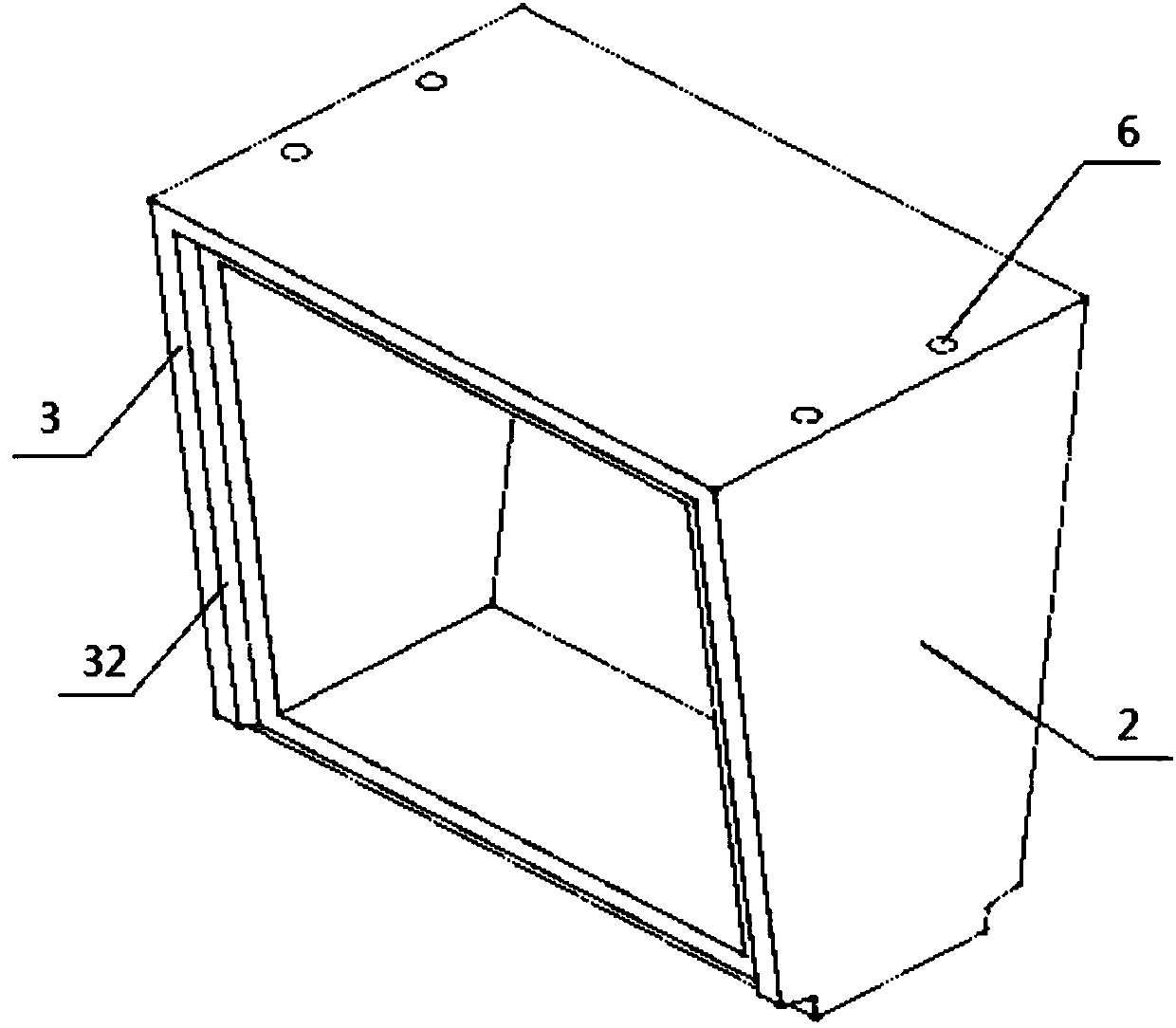

[0016] like figure 2 Shown: positive trapezoidal segment structure 1, the width of the bottom opening is 2.5m~3.0m (the standard section width can be adjusted appropriately according to the actual situation), the width of the upper opening is 1.5~2.0m, and there are protrusions 31 around the fracture. The mouth 31 is shaped on a waterproof rubber strip mounting groove 4, the mounting grooves 4 on both sides are positioned at the front of the convex hole 31, and the upper and lower mounting grooves 4 are positioned at the top surface of the convex hole 31. like Figure 4 As shown: the groove bottom 5 with rounded corners is set at the junction of the mounting grooves 4 on both sides and the upper and lower mounting grooves 4 for transitional treatment. Reserve hoisting bolt holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com