Tool for bar-shaped deep groove foundation excavation and grouting

A strip-shaped and deep-groove technology, which is applied in the field of excavation and grouting tools for strip-shaped deep-groove foundations, can solve problems such as cumbersome excavation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

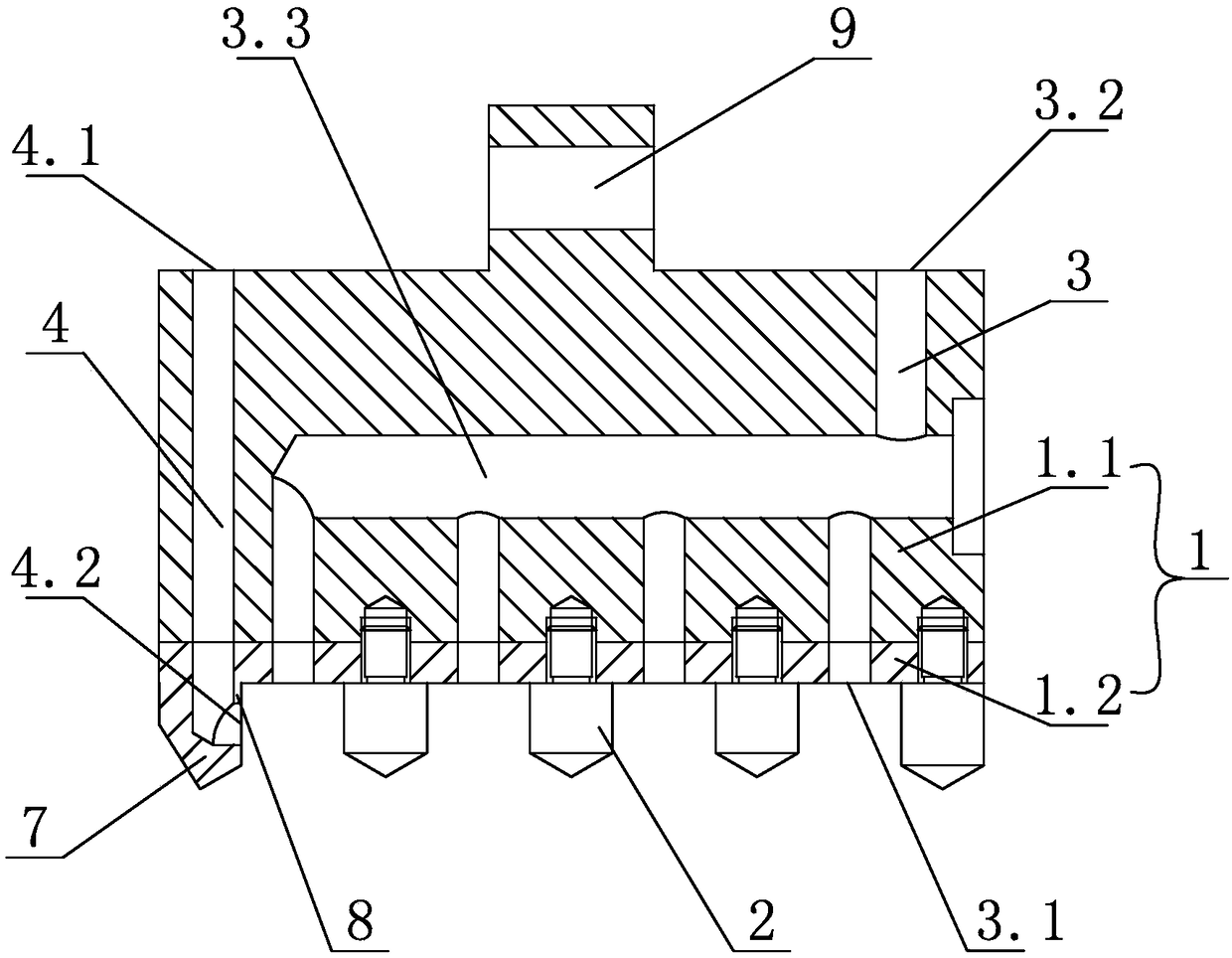

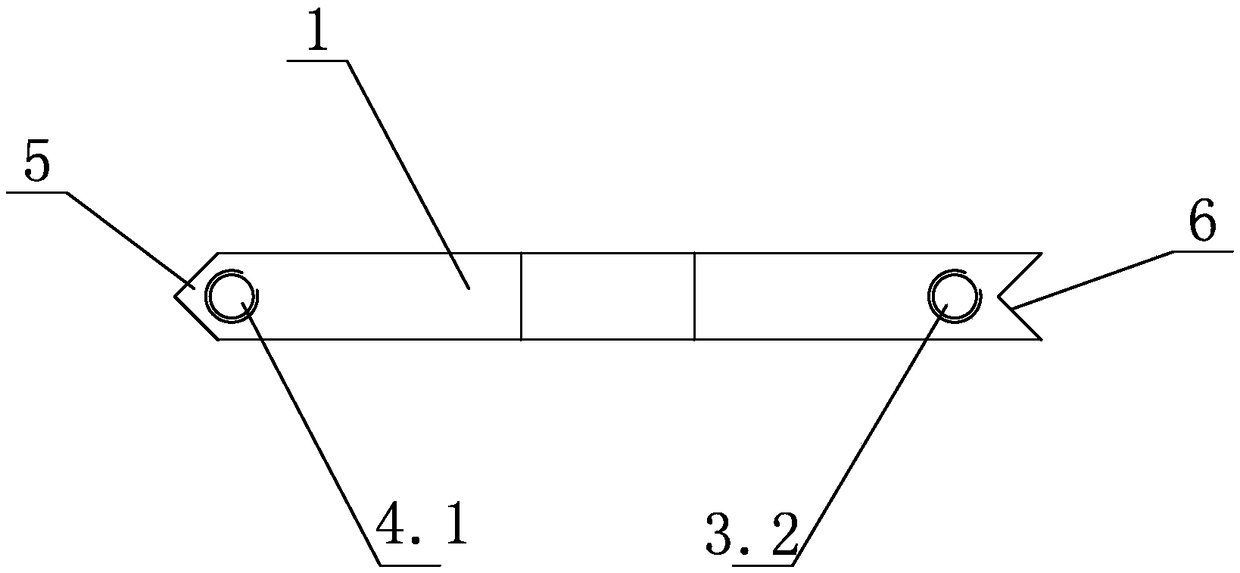

[0020] Such as Figure 1 to Figure 2 As shown, a strip-shaped deep groove foundation excavation and grouting cutter includes a strip-shaped blade body 1 and several cutter heads 2; the cutter heads 2 are arranged on the strip surface at the front end of the blade body; The slag discharge hole 3 for discharging waste slag and the grouting hole 4 for injecting retaining wall grout. Both sides of the blade body 1 are protrusions 5 and grooves 6 which can cooperate with each other respectively. The cross-section of the protrusion 5 can be triangular, rectangular or arc-shaped.

[0021] In order to connect with external equipment, the slag discharge outlet 3.2 of the slag discharge hole 3 and the grouting inlet 4.1 of the grouting hole 4 are all arranged at the rear end of the knife body 1; Head 2 sides. The front end of the knife body 1 is provided with a boss 8; the front end of the boss 8 is provided with a slotted cone 7;

[0022] The boss 8 is located on one side of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com