Non-destructive blasting excavation method without integrated rock interface foundation

An interface and basic technology, applied in the field of non-destructive blasting excavation, to achieve the effect of reducing blasting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the non-destructive blasting excavation method for unconformable rock interface foundations involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024]

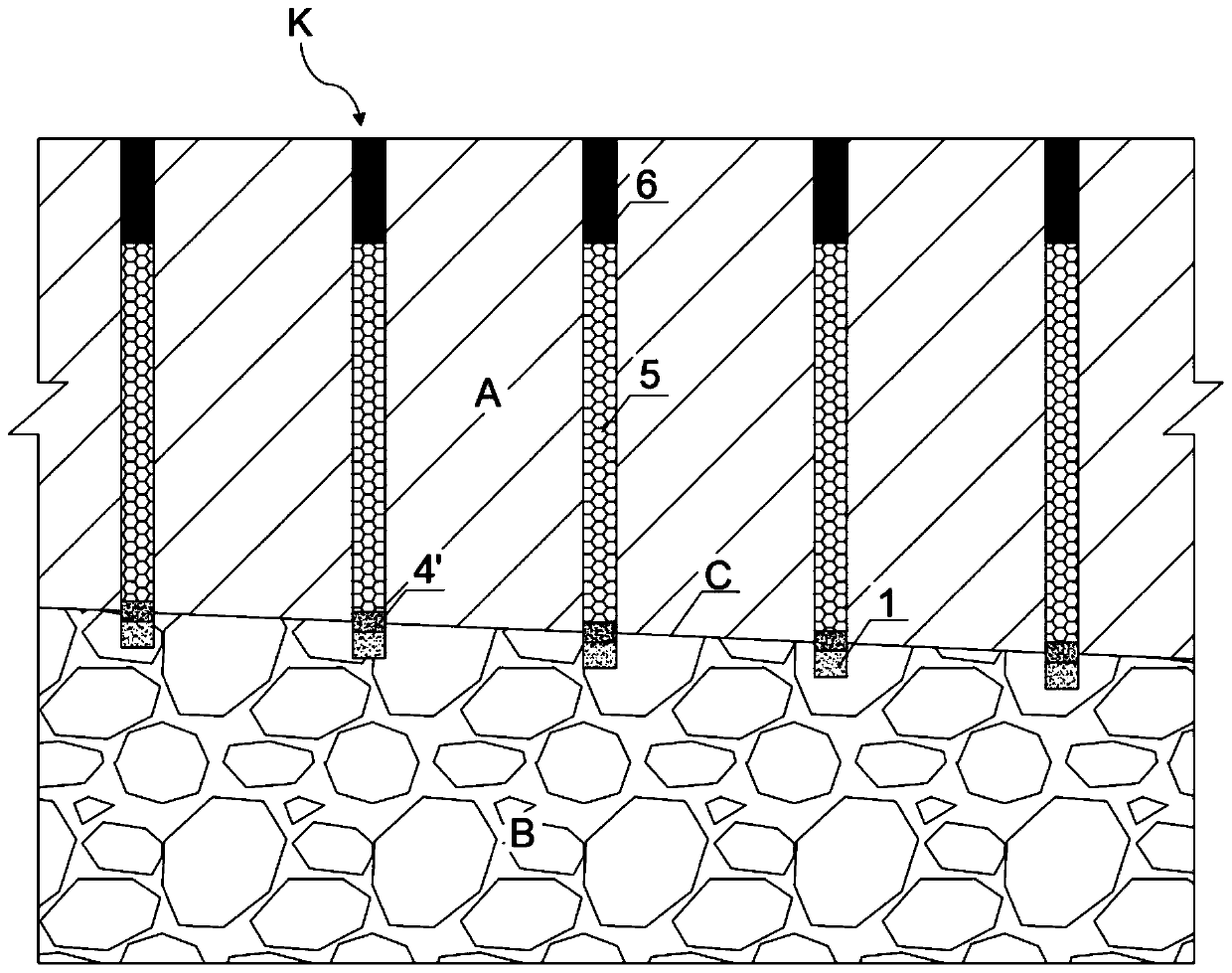

[0025] In the excavation of a horizontal dam foundation of a hydropower station, the overlying rock mass A to be blasted is the rock mass A, and the underlying rock mass B is the rock mass used as the permanent foundation surface. There are obvious differences in the lithology of the two layers of rock mass. Belonging to a typical unconformity rock interface C, it is necessary to improve the flatness of the foundation surface and control the blasting damage to the underlying rock mass B during the excavation of the dam foundation rock mass. Shallow hole step blasting, vertical blasting, drilling diameter D = 90mm, drilling depth of about 5m, super depth of 0.3m, plugging length of 1.5m, hole spacing of 1.8m×1.8m, hole bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com