The Construction Method of Squeezing Blasting and Road Repairing without Protective Layer on the Full Section of the Bench in the Lower Tunnel

A technology of extrusion blasting and protective layer, which is applied in the direction of tunnels, earthwork drilling, mining equipment, etc., can solve the problems of accelerating construction progress, high safety risks, and low work efficiency, and achieve the effect of speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

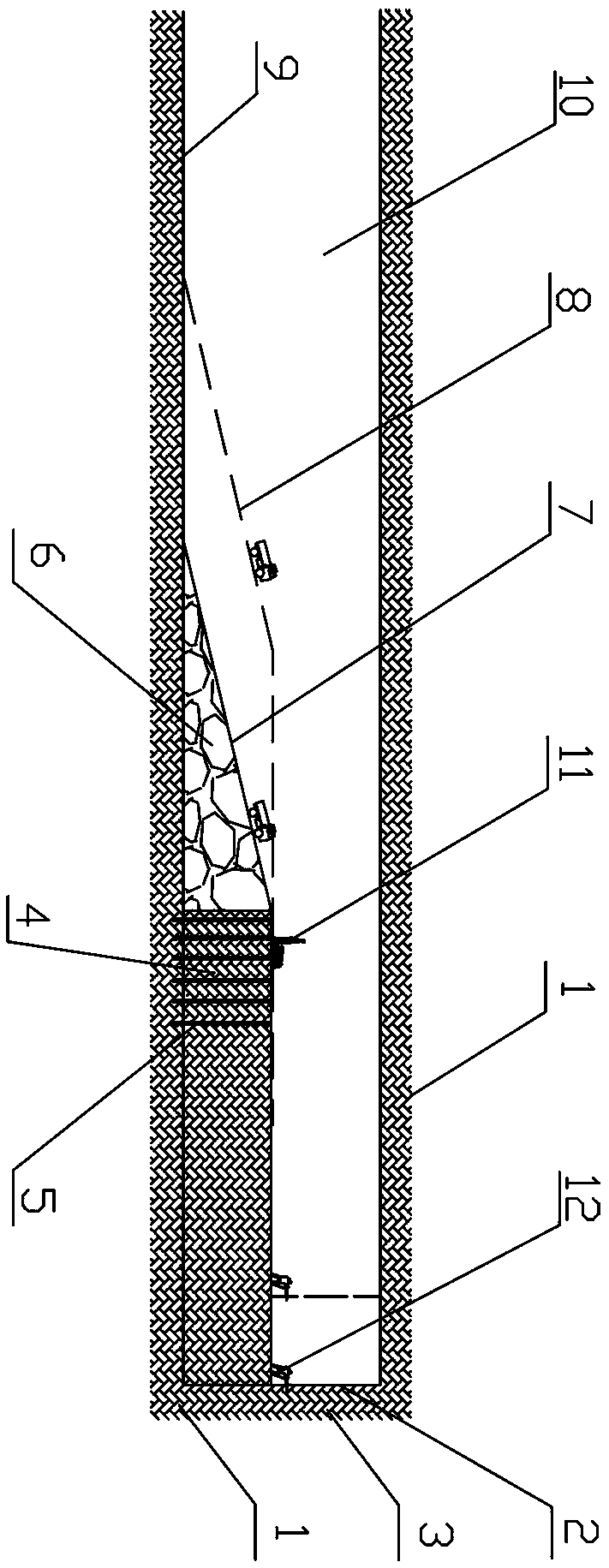

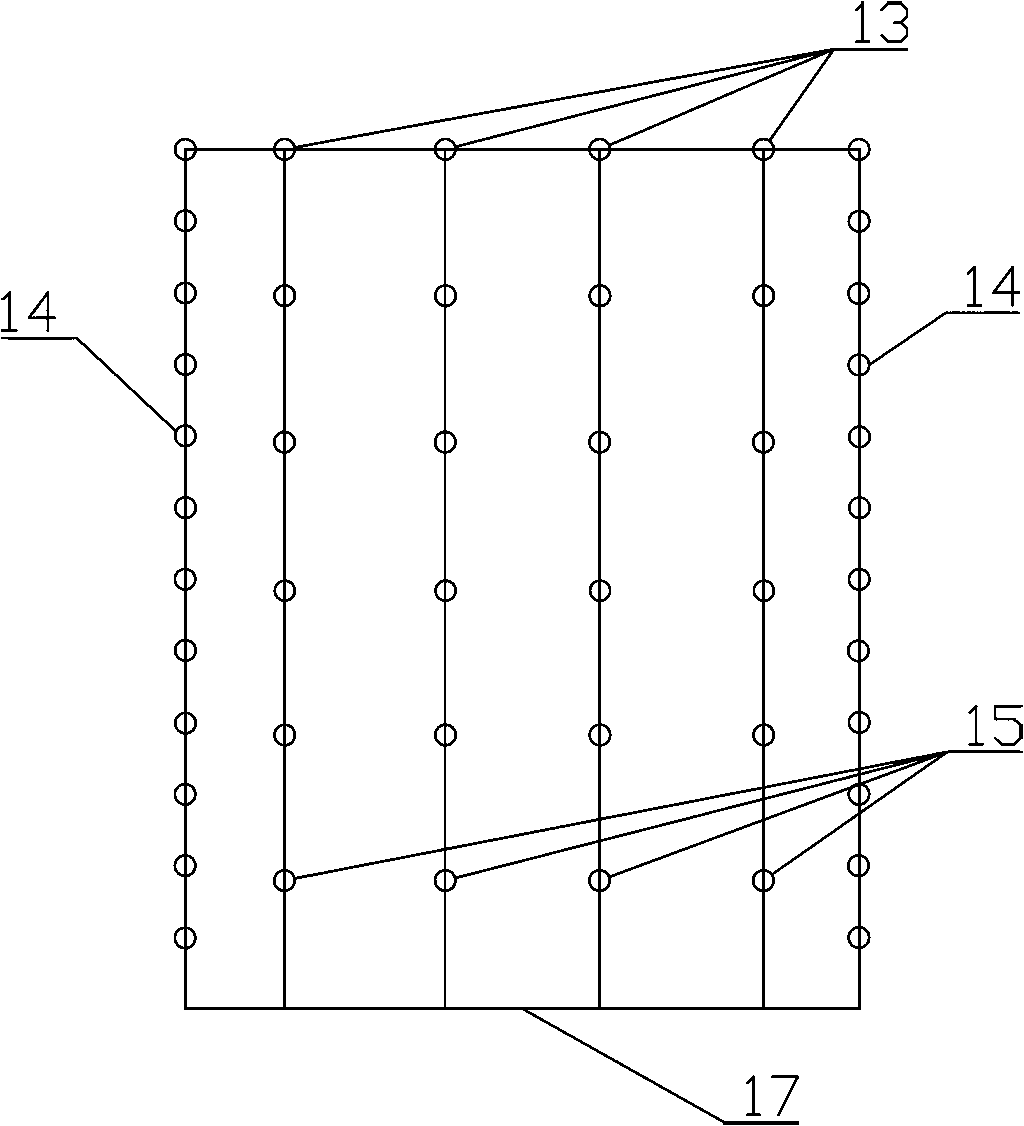

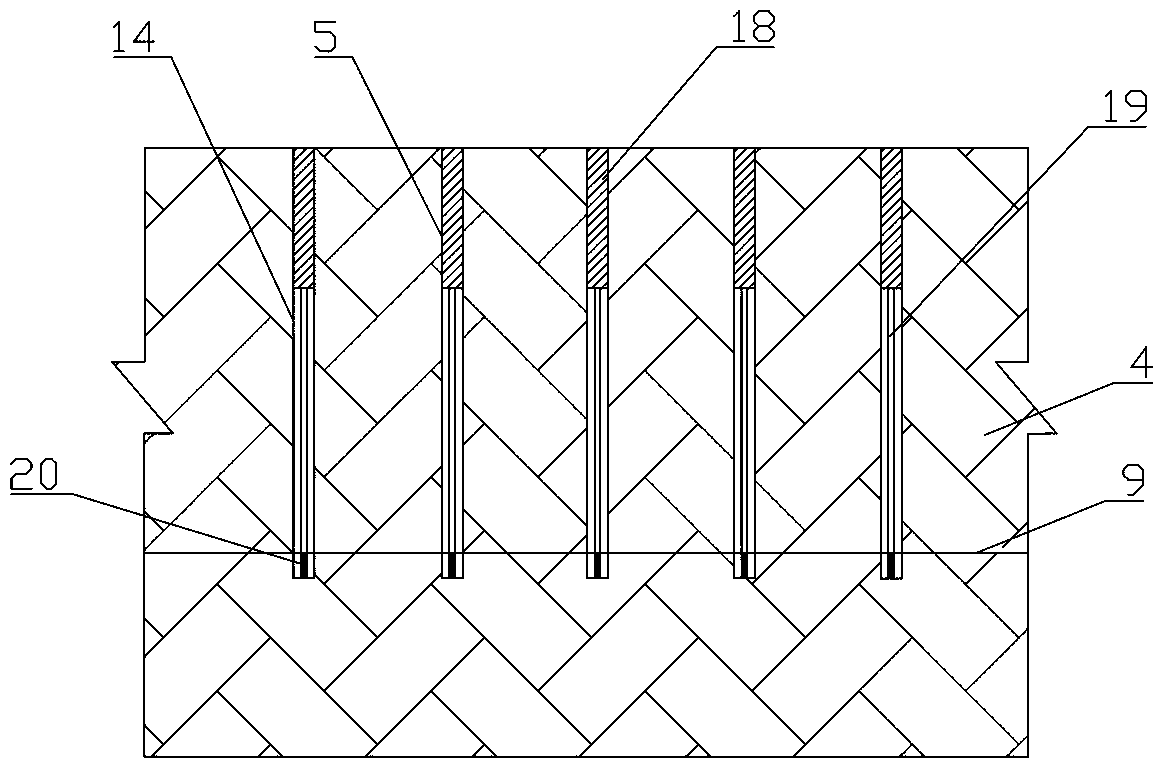

[0079] The construction method of extrusion blasting with no protective layer on the full section of the lower step of the tunnel and road repair includes the following steps:

[0080] Step 1: Use the excavation method of the step method. According to the size of the tunnel section, the width B=9.6m and the height H=12.5m. Steps, the height of the upper step is H 1 =6.8mm, lower step height H 2 =5.7m. The hole is excavated by drilling and blasting method, and large-scale excavating and transporting machinery excavates and transports slag.

[0081] Step 2: Excavate the upper steps first. The drilling and blasting excavation of the upper steps is carried out in advance, and the lower steps are used as the slag discharge and traffic roads of the upper steps. The upper steps are excavated by conventional step full-face blasting method, and horizontal holes are drilled by hand wind drills.

[0082] Step 3: When the excavation footage of the upper steps is 60m, the lower steps ...

Embodiment 2

[0127] Embodiment 2 Example effect of blasting

[0128] A water conservancy construction project was excavated by rock blasting. After repeated blasting, it was observed that the height of the blast pile was 1.5-2m, and the blast pile was uniform. The empty slot from the first row of blastholes to the front of the airport is filled with blasting slag, and there is no large forward rush phenomenon; the original slag pile in front has no obvious displacement phenomenon. The last row of gun holes is slightly overturned forward. The pre-splitting blasting of the side walls on both sides has no major inward rollover phenomenon.

[0129] After several times of blasting, excavation and bottom inspection showed that there were few under-excavation phenomena on the bottom slab of the foundation surface, most areas reached the design elevation, and there was little over-excavation phenomenon. There are basically no large blasting cracks at the blastholes on the bottom plate of the fou...

Embodiment 3

[0131] Example 3 Excavation of the tunnel by the full-section alternate excavation method of positive steps

[0132] The hydraulic tunnel of a newly built reservoir is a non-pressure tunnel of the city gate type, with a length of 516m, an excavated section with a height of 12.5m and a width of 9.6m. The rock is andesite porphyrite.

[0133] Divide the tunnel into upper and lower steps, and excavate in layers. The upper steps are 6.8m high and the lower steps are 5.7m high. Excavation by blasting is carried out by drilling horizontal holes with hand-pneumatic drills. The full-section excavation of the upper and lower steps is alternately excavated. When drilling and blasting the full-section excavation of the upper step, the lower step is used as the slag discharge road. Due to the high height of the steps on the lower floor, the required slope road is long, 40-50m. However, the horizontal hole is drilled with a hand-pneumatic drill. The length of each blasting excavation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com