Thermosetting adhesive with low fusing temperature

A fusing temperature and thermosetting technology, applied in the application field of low fusing temperature thermosetting adhesives in particle board materials, can solve the problems of high cost of metal modules, high dependence on installation conditions, poor sound insulation effect, etc., to improve the free volume , the effect of chain segment movement to improve and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

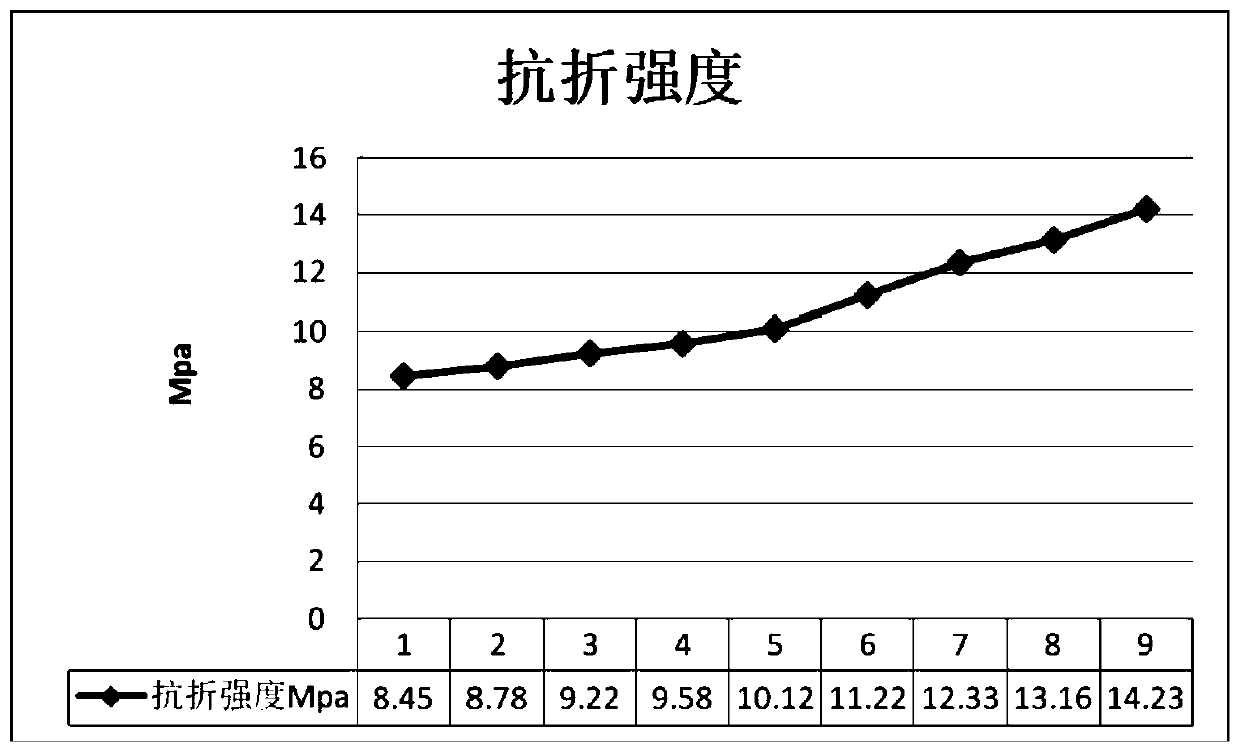

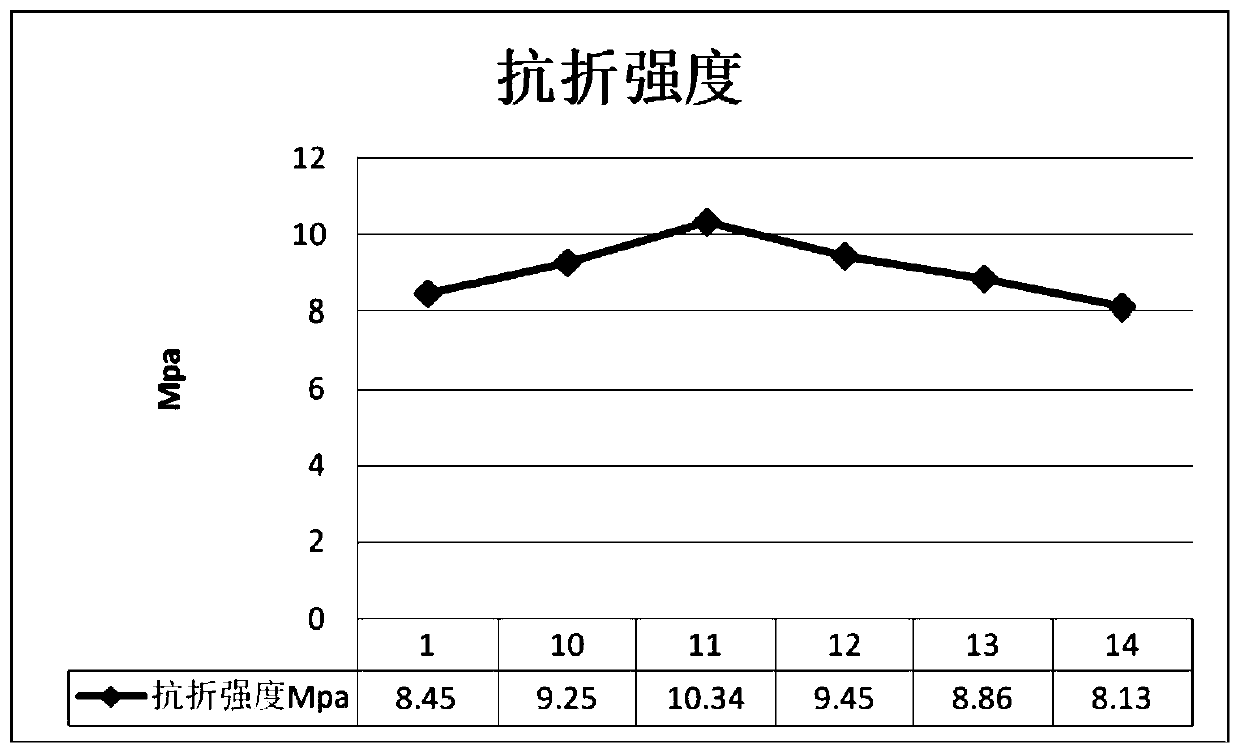

Embodiment 1

[0050] Weigh 100 parts of 120-mesh machine-made sand with roundness and sphericity of 0.8, weigh 5 parts of gel solvent, 9 parts of isocyanate, of which 4,5-epoxycyclohexane-1,2- Diglycidyl diformate accounts for 3.5 parts (alicyclic epoxy resin), 1,6-hexanediol diglycidyl ether accounts for 0.1 part (aliphatic epoxy resin), silane accounts for 0.0075 parts, graphene dispersion accounts for 0.0025 parts, isophorone diamine accounted for 1.39 parts.

[0051] First, fully mix the gel solvent in the rubber mixer; then pour the gel solvent into the mixer and mix with the aggregate particles; then put the mixture in the distribution hopper, and the outlet of the distribution hopper is adapted to the width and thickness of the mold ;The mold continuously passes horizontally under the hopper through the transmission mechanism. After the mold passes through the hopper, a layer of particle mixture is evenly arranged in various parts of the mold; then the mold passes through the vibrati...

Embodiment 2

[0054] Compared with Example 1, only the number of isocyanate is changed to 8 parts, and the rest of the materials and manufacturing process are consistent.

Embodiment 3

[0056] Compared with Example 1, only the number of isocyanate is changed to 7, and the rest of the materials and manufacturing process are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com