Nutshell flying preventive cracker

A nut shell and anti-flying technology, applied in household appliances, applications, kitchen utensils, etc., can solve the problems of nut shell cracking and splashing, fruit cracking, waste, etc., and achieve high practicability, promotion value, and good blocking effect. , The effect of preventing splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

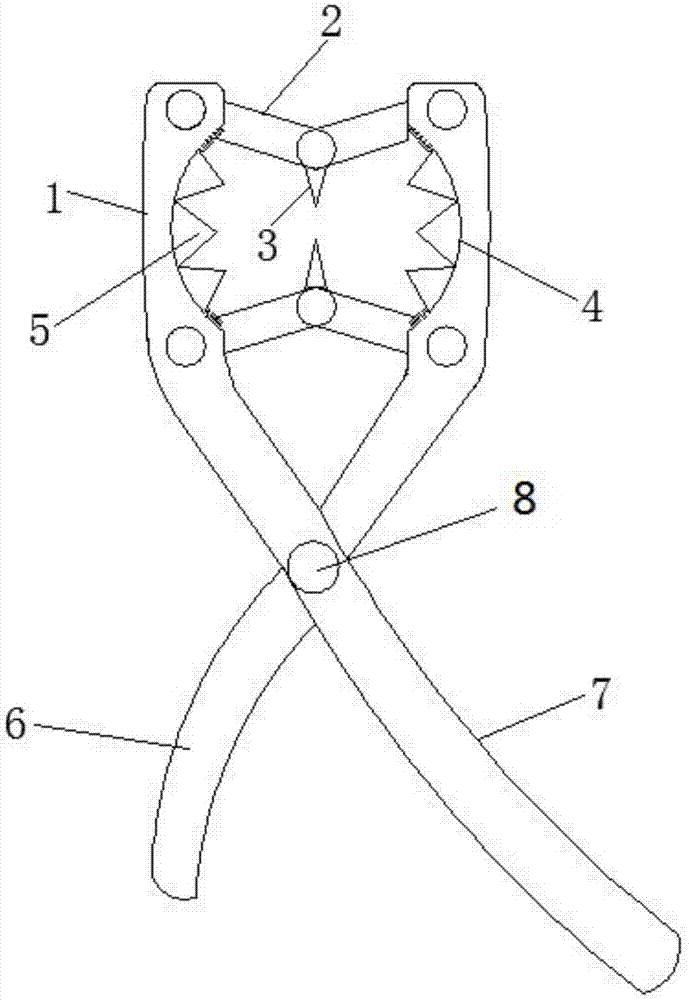

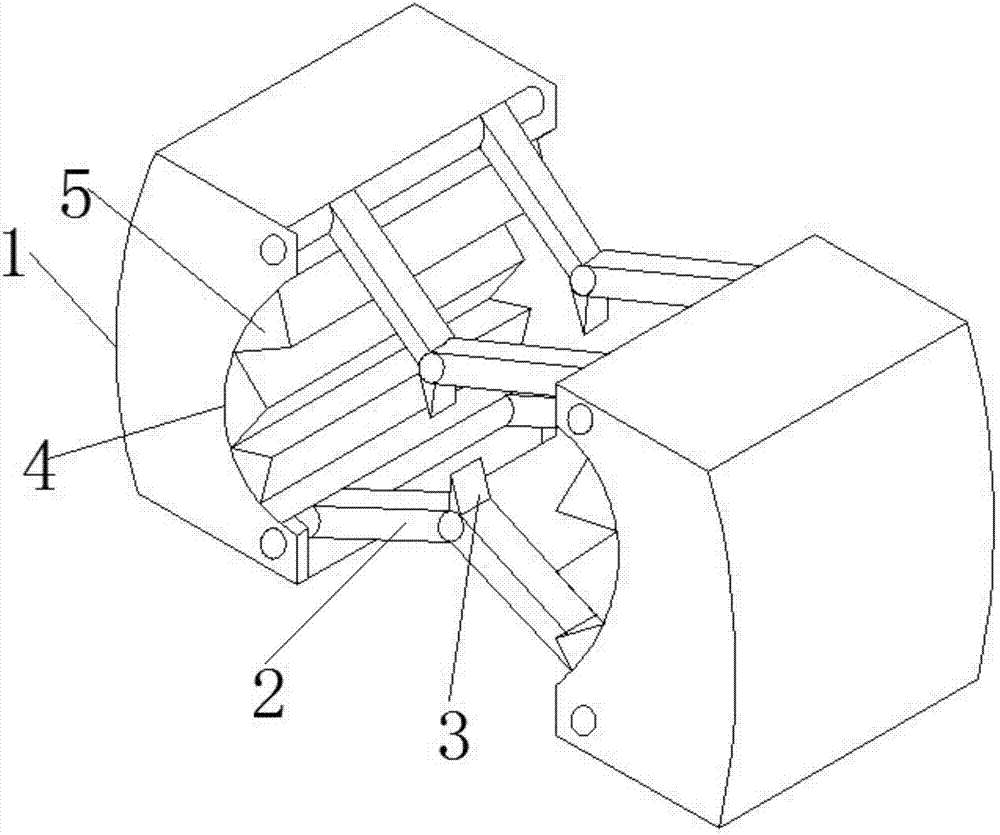

[0022] as attached figure 1 The shown nutshell anti-flying clamp of the present invention includes two clamping handles, the two clamping handles are hingedly connected by a pin shaft 8, one end of the clamping handle is a squeeze end, and the other end is a hand-held end, and the squeeze handle The end includes extruding blocks 1 respectively arranged at the ends of the two clamping handles, and a hinged longitudinal extruding device is arranged between the two extruding blocks 1; the longitudinal extruding device includes two sets of longitudinal extruding assemblies; The longitudinal extrusion assembly is composed of two connecting rod groups and an extrusion body 3; the two ends of the two connecting rod groups are hingedly connected with the extrusion blocks 1 on both sides respectively, and the middle hinges of the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com