Transmission device for composite board sleeve-free edge sealing machine

A transmission device and edge banding machine technology, which is applied to household components, wood processing appliances, etc., can solve the problems affecting the accuracy of extrusion edge banding, insufficient internal support force, and affecting processing and production, so as to improve the efficiency of transmission and extrusion molding , Ensure internal support and stability, and reduce the effect of later use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

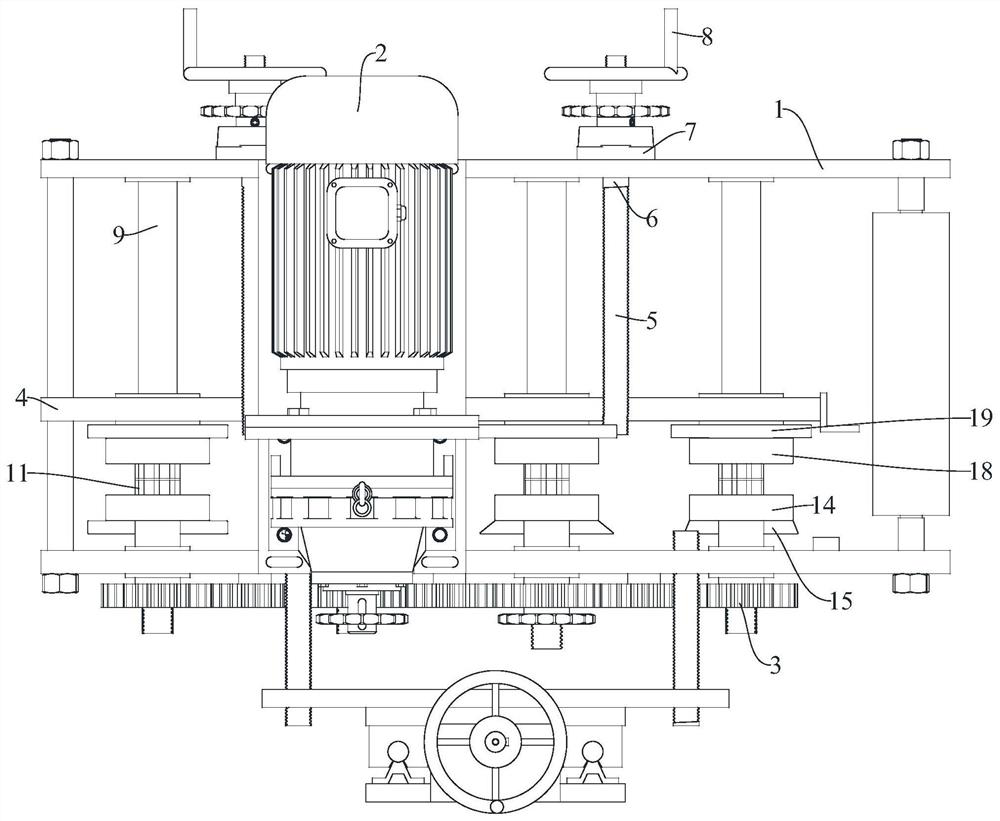

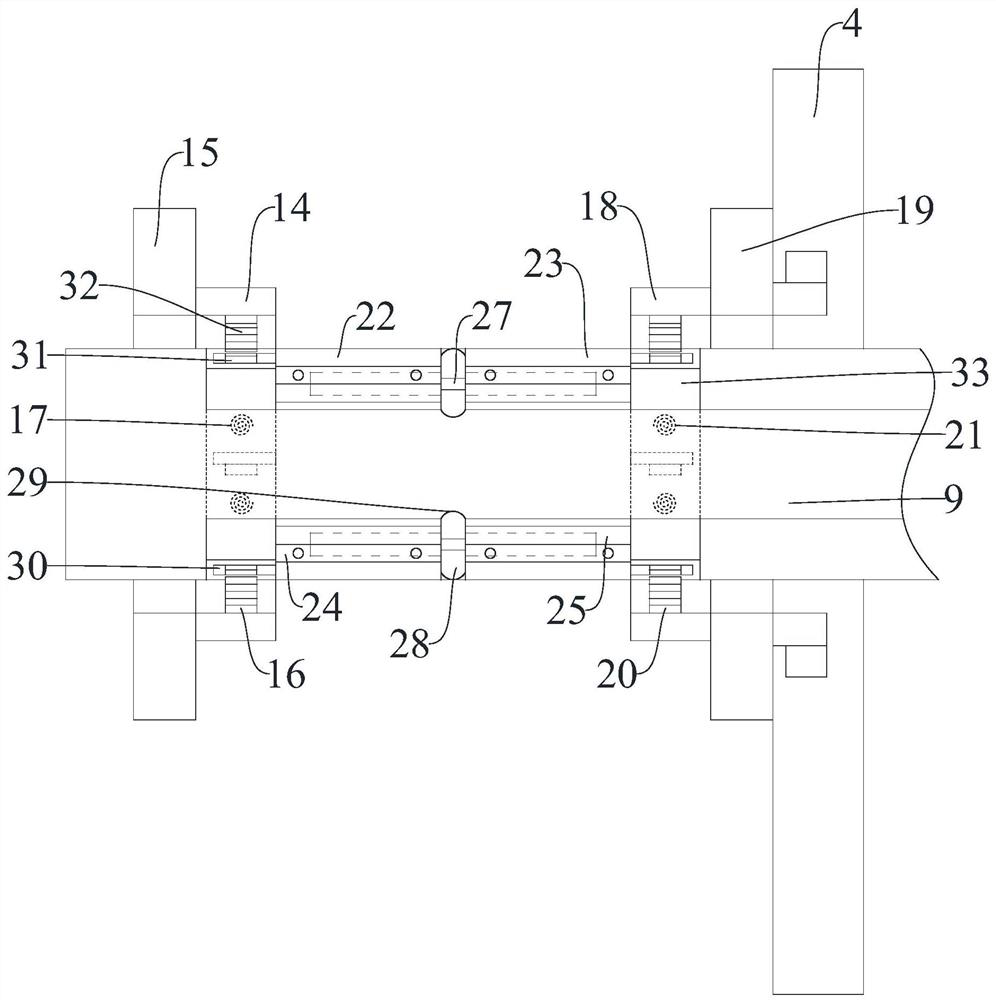

[0027] Embodiment: People turn over the external adjustment handle 8 by manual control, and drive the horizontal external thread adjustment rod 5 to rotate, thereby driving the internal adjustment plate 4 to translate along the external guide roller group, and the horizontal external thread adjustment rod 5 runs through the internal adjustment plate 4 and the Internal adjustment plate 4 threaded connection.

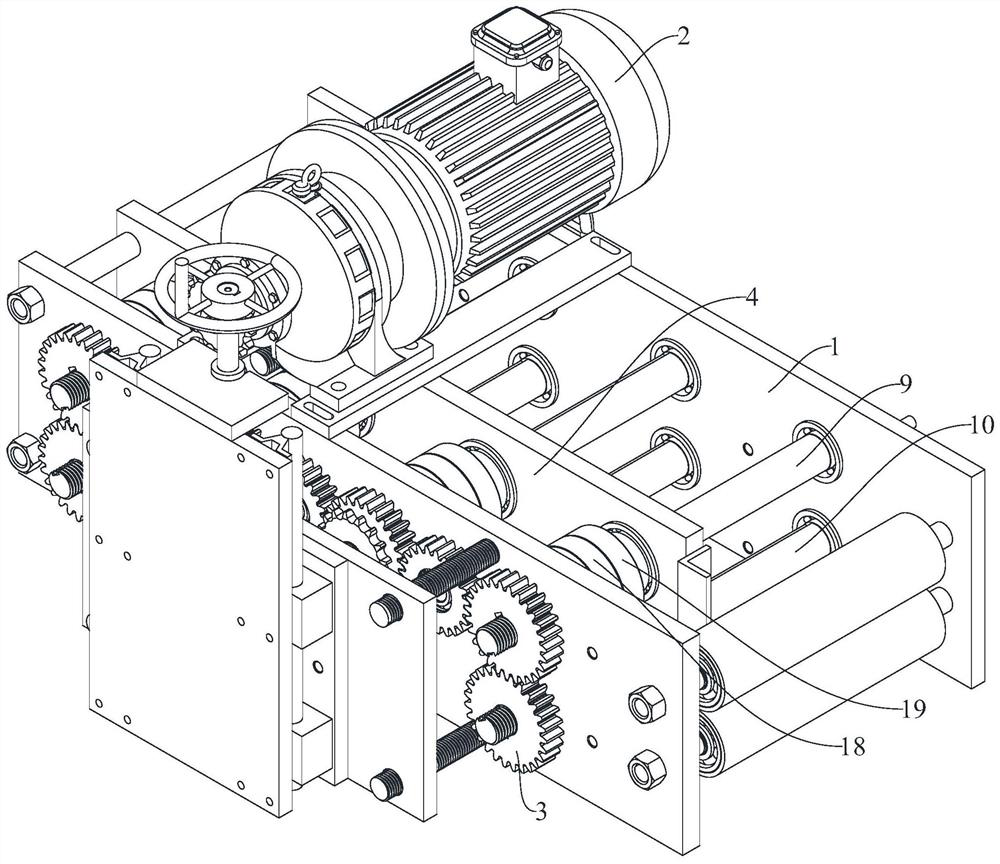

[0028] Further, in order to cooperate with the movable assembly, the outer guide roller group includes an upper drive roller 9 and a lower drive roller 10 that move inside the outer main frame 1 through a lateral rotation shaft, and the upper drive roller 9 and the lower drive roller The cylinder 10 runs through the external main frame 1 through the lateral rotating shaft and is axially fixedly connected with the side gear transmission group 3. The upper drive roller 9 and the lower drive roller 10 are provided with 6 strip-shaped storage grooves 11 on the outer arc surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com