Manufacturing method of spiral bearing frame for electronic parking brake system, produced by lateral extrusion cold forging process

A technology of parking brake and manufacturing method, applied in the direction of manufacturing tools, forging/pressing/hammering machinery, wheels, etc., can solve the problems of high manufacturing cost, poor productivity, inferior to forging products, etc., and achieve excellent hardness and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Referring to the accompanying drawings, a method for manufacturing a spiral bearing frame for an electronic parking brake system using side extrusion cold forging according to an embodiment of the present invention will be described in detail.

[0038] Such as Figure 1 to Figure 11 As shown, the manufacturing method of the spiral bearing frame for the electronic parking brake system using the side extrusion method cold forging of the present invention includes: the manufacturing method of the electronic parking brake system using the side extrusion method cold forging , characterized by including:

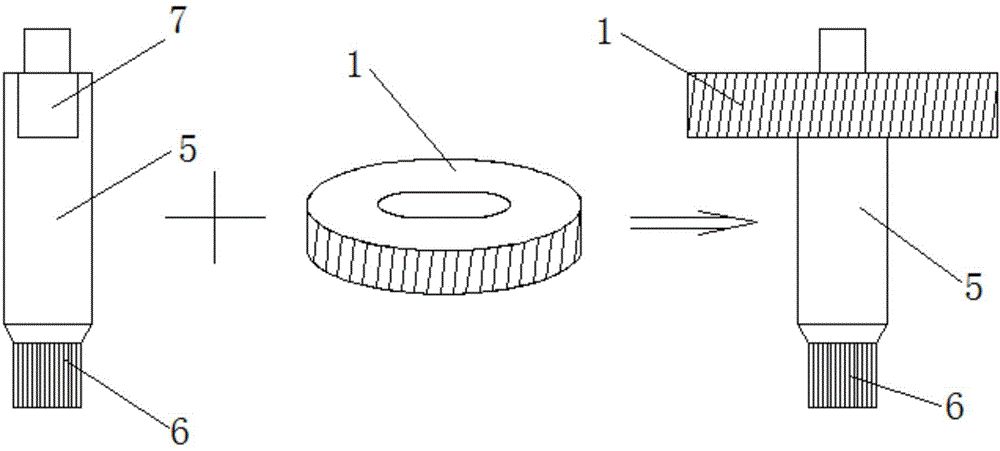

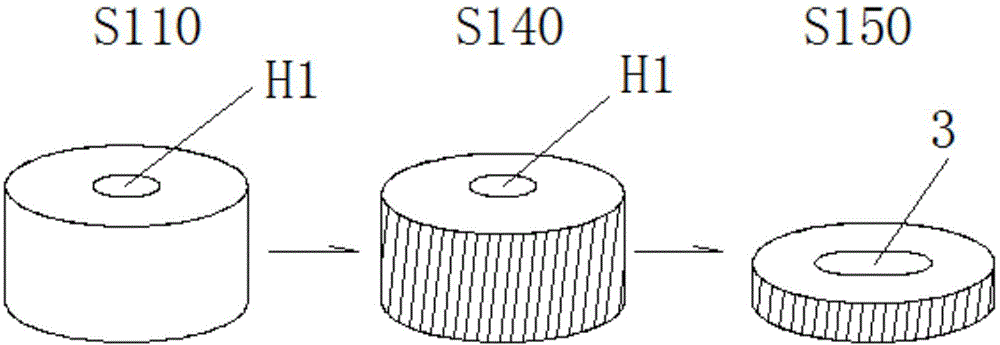

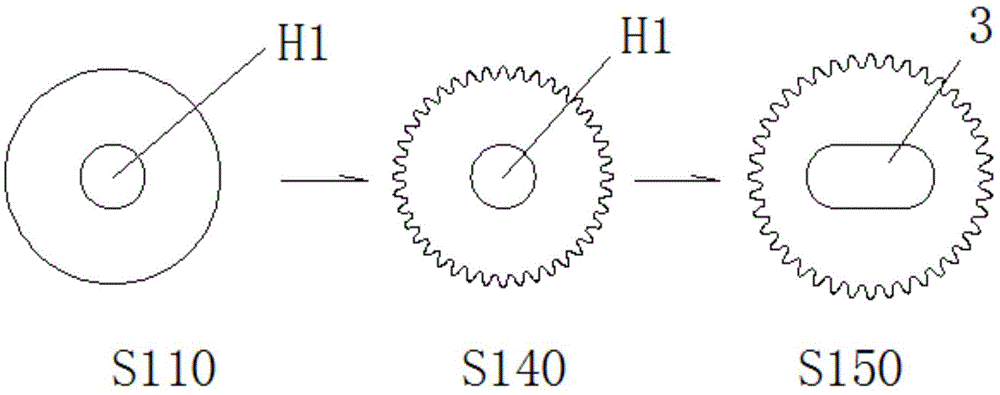

[0039] Helical gear manufacturing step S100, forming a hollow assembly groove 3, and manufacturing a helical gear 1 with helical gear teeth formed on the outer periphery; carrier shaft manufacturing step S200, manufacturing a spline portion 6 formed on one end, and forming a spline portion 6 on the other side. There is a carrier shaft 5 corresponding to the assembly split-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com