Novel movement recoil type hot extrusion forming and processing method

A process method and hot extrusion technology, applied in the field of hot extrusion forging, can solve the problems of large damage to the lower die, complex die structure, inability to extrude, etc., and achieve reasonable power distribution, simple die structure and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

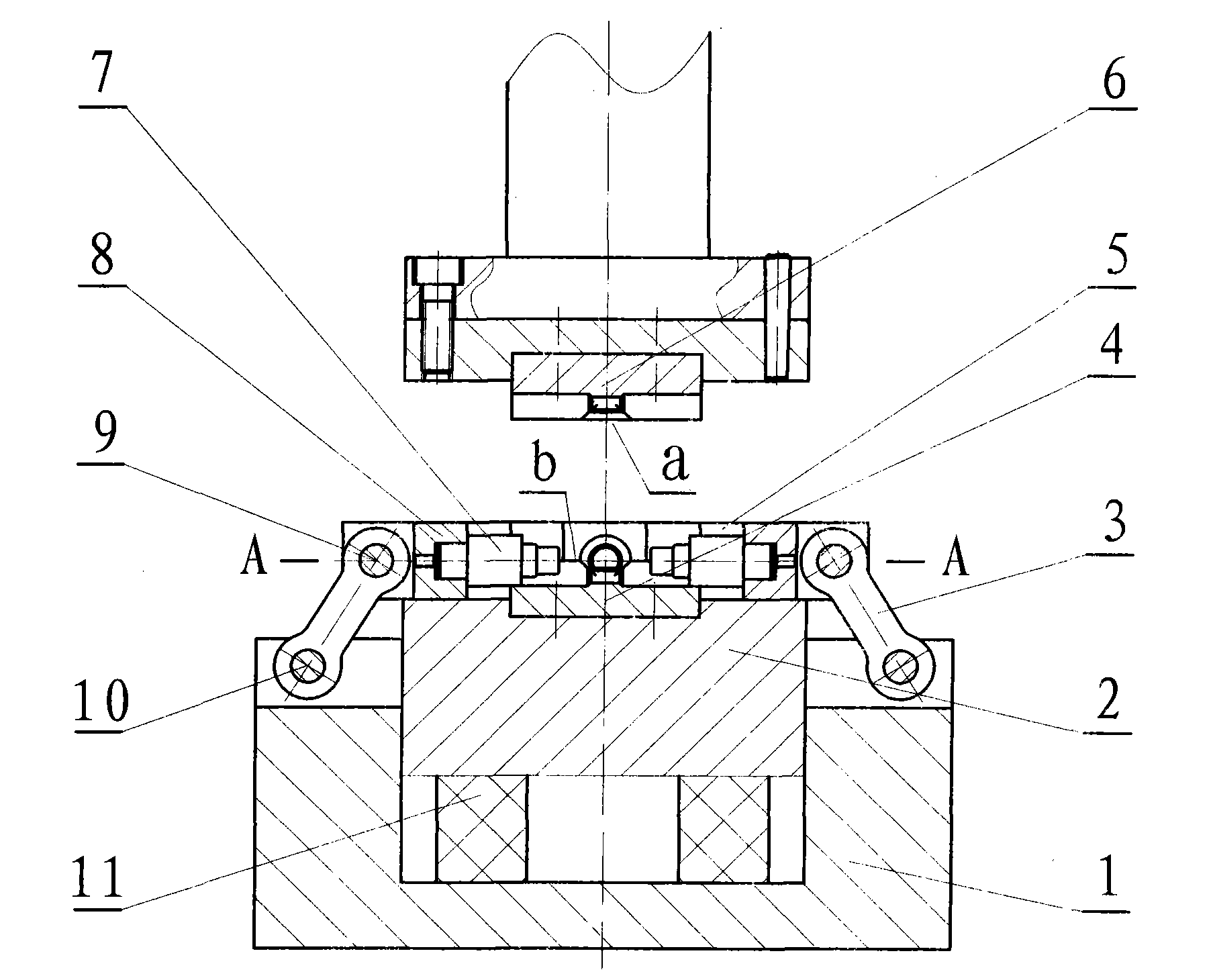

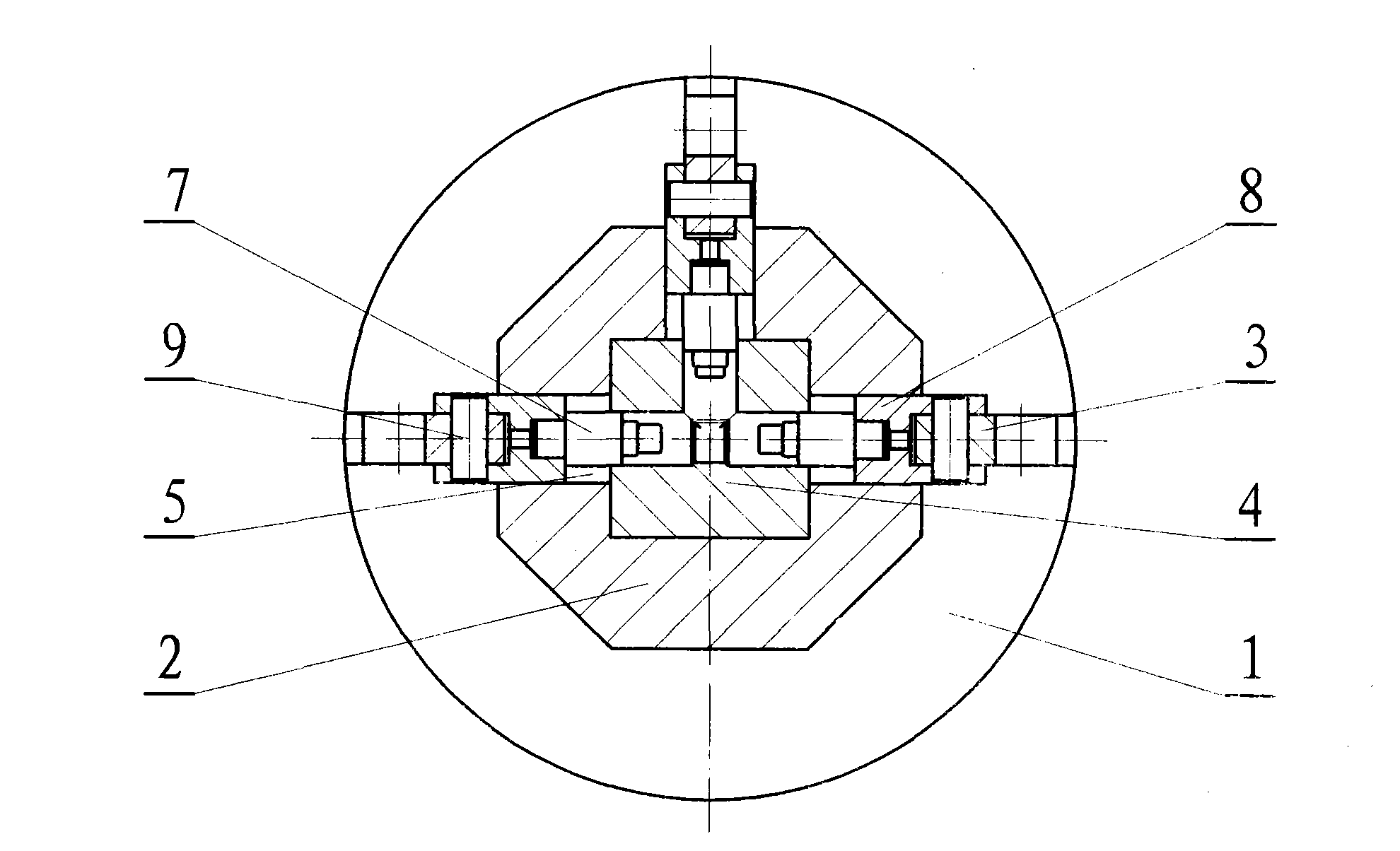

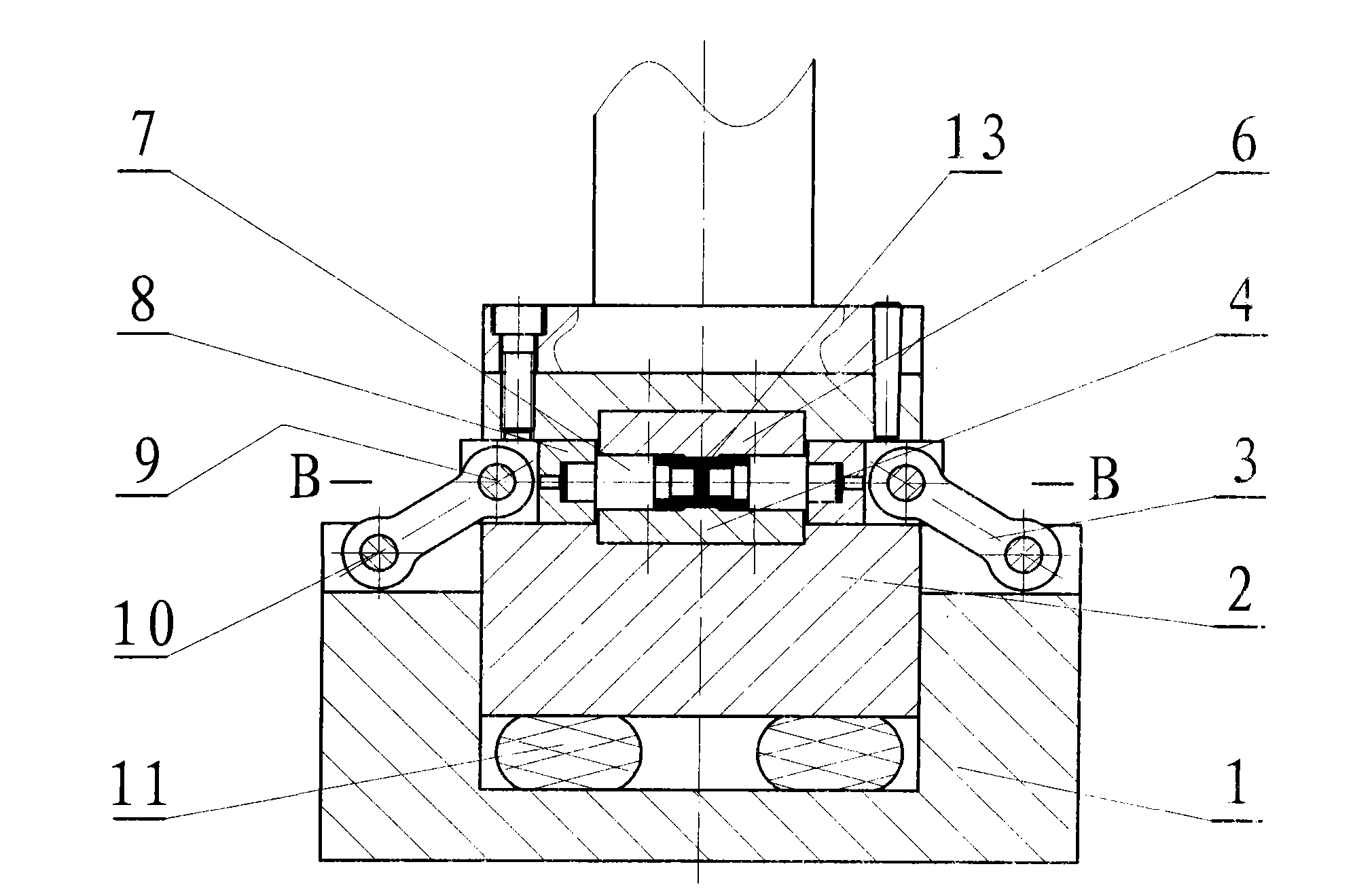

[0013] Such as figure 1 , figure 2 , Figure 5 , Figure 6 As shown, the lower mold base 2 and the support base plate 1 form a vertical movement pair in the form of shaft and hole clearance fit, wherein the support base plate 1 is fixed, and an elastic rubber 11 is arranged between the two planes; the support base plate 1 and the connecting rod 3 form the rotary pair of the fixed hinge through the lower pin 10, in which the supporting base plate 1 is fixed; the connecting rod 3 and the transverse punch base 8 form the rotary pair of the movable hinge through the upper pin 9; the transverse punch Between the base 8 and the lower mold base 2, a horizontal movement pair is formed in the form of a key and a keyway, wherein the lower mold base 2 is fixed in the horizontal direction; the horizontal punch 7 is installed in the horizontal punch base 8. Such as image 3 , Figure 4 As shown, put the hot (warm) state metal blank into the lower die 4, and start the press at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com