Horizontal detonator full-automatic bayonet machine

A fully automatic, bayonet technology, used in detonators, offensive equipment, etc., can solve the problems of dangerous operators and low production efficiency, and achieve the effects of ensuring life safety, improving production efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

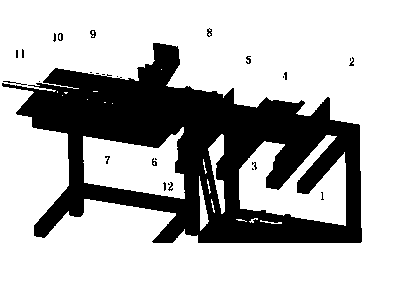

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

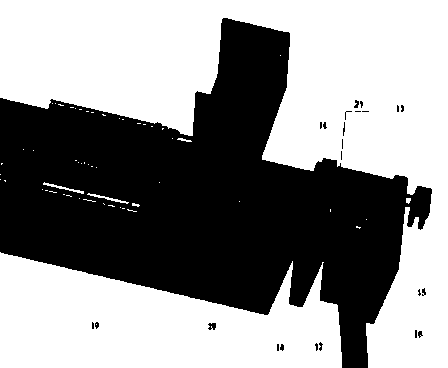

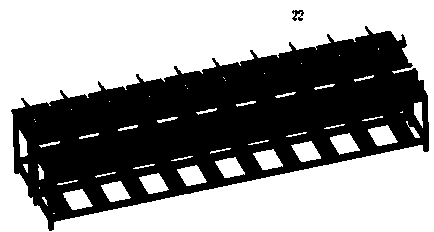

[0014] The piston of shell delivery cylinder 9 is extended, and the shell is ejected from the small hole in the side wall of the shell holding box 8, and sent into the shell chuck hole of the shell transfer cylinder 7, and the shell transfer cylinder 7 is retracted, and the The shell is sent to the guide groove 14 of the shell, and the piston of the shell push cylinder 11 is extended to push the shell out of the cylinder 10, and the shell is sent to the set bayonet position by using the ejector pin on the cylinder 10 to push out the shell. At the same time, the charge feeding head cylinder 5 sends the detonator drug heads arranged on the charge head mold 4 into the detonator shell, and the piston of the bayonet action cylinder 1 stretches out, and the reciprocating seat 15 is driven by the connecting rod 3 to move, and the reciprocating seat 15 Squeeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com