Magnesium alloy thin wall pipe bidirectional extrusion forming mold and forming method of magnesium alloy thin wall pipe

A thin-walled pipe, bidirectional extrusion technology, applied in metal extrusion dies, metal extrusion, metal extrusion control equipment, etc., can solve the lack of high-performance magnesium alloy thin-walled pipe manufacturing methods, reduce the mechanical properties of formed pipes , Light alloy casting microstructure shrinkage, porosity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

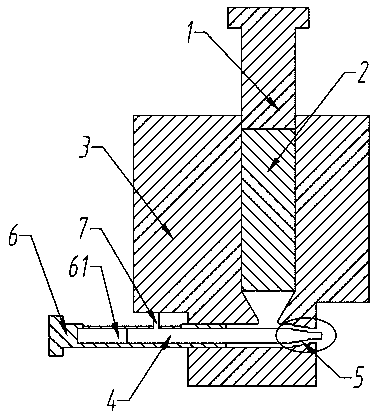

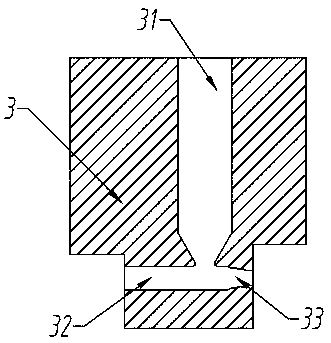

[0023] Such as figure 1 , figure 2As shown, the present embodiment provides a bidirectional extrusion molding die for a magnesium alloy thin-walled pipe, including a die 3, an extrusion rod and an extrusion needle 4; Cavity 31, lateral extrusion cavity 32 and concave mold cavity 33, described forward extrusion cavity 31 is vertically arranged, and lateral extrusion cavity 32 and concave mold cavity are horizontally arranged, and lateral extrusion cavity 32 and The cavity of the concave mold is coaxial and runs through the concave mold 3, and the connection between the lateral extrusion cavity 32 and the cavity of the concave mold is located directly below the forward extrusion cavity 31; and the lower necking area; the extruding rod includes a forward extruding rod 1 and a lateral extruding rod 6, the upper end of the forward extruding rod 1 is connected with the main cylinder of the hydraulic press, and the lower end is connected with the forward extruding rod 6. The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com