Garment steamer with power-off temperature prompt function and control method of garment steamer

A technology of shutdown temperature and control method, which is applied to home appliances, tidying appliances, laundry room devices, etc., can solve the problem of no display or warning of the temperature of the ironing head on the clothes ironer, and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

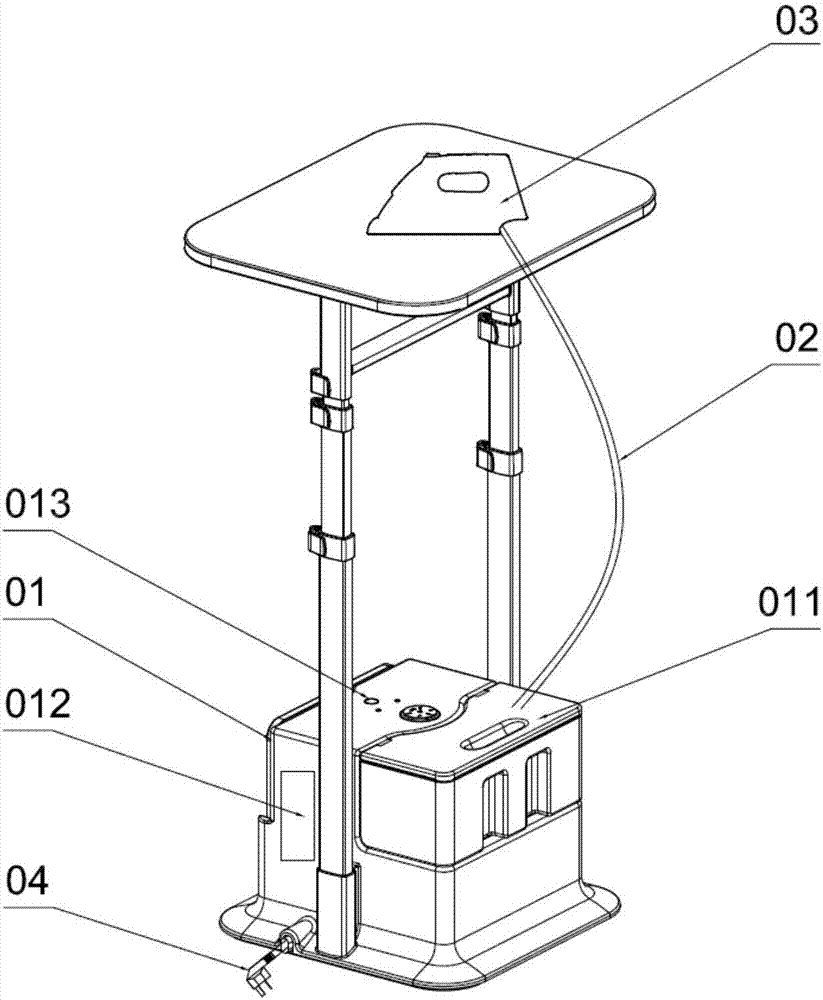

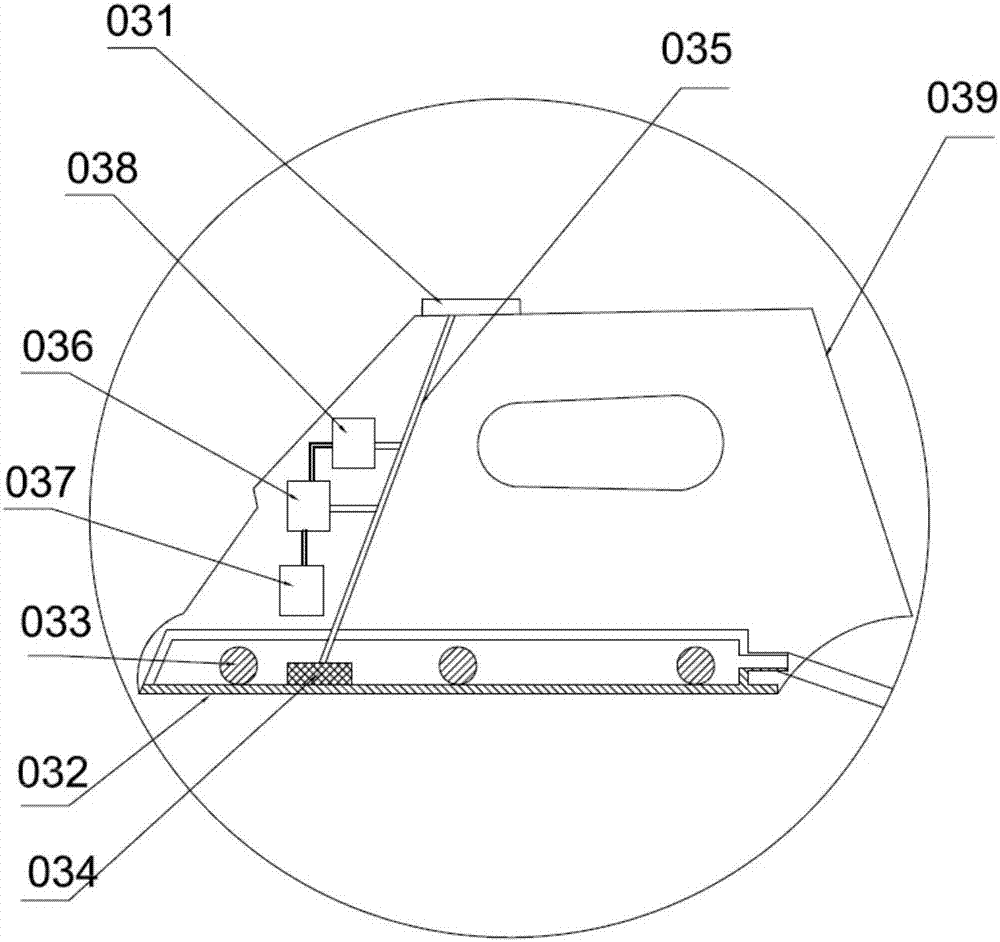

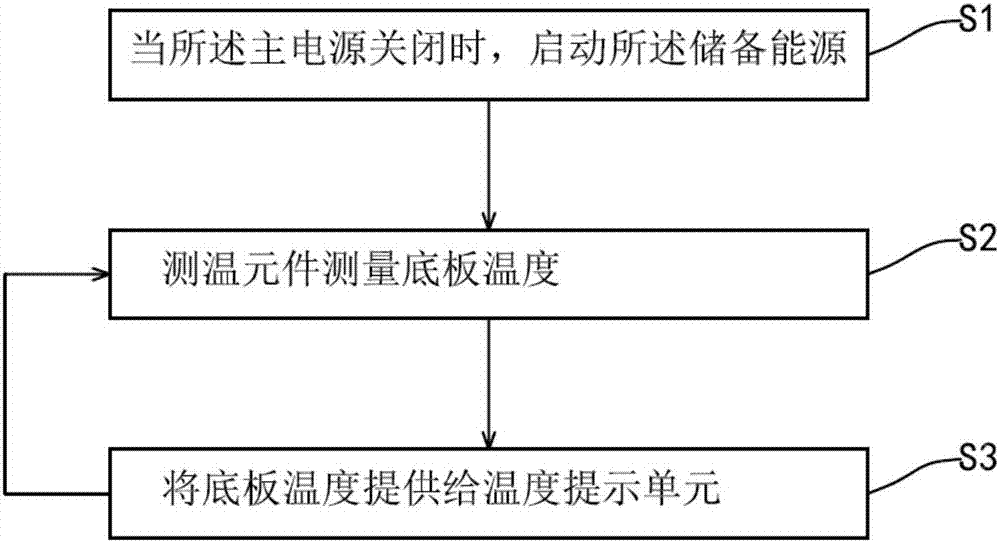

[0035] For the structural diagram of the garment steamer with shutdown temperature prompt of the present invention, see Figure 1 to Figure 2 , including a host 01, a conduit 02 and a perm 03. The host 01 is provided with a water tank 011, a control panel 012 and a main switch 013. The perm 03 is connected to the water tank 011 on the host 01 through the conduit 02. The perm 03 includes a bottom plate 032, The heating element 033, the temperature measuring element 034 and the temperature prompting unit 031 also include the main power supply for the host 01, the heating element 033, the temperature measuring element 034 and the temperature prompting unit 031, and the heating element 033 is installed on the base plate 032 and heats it , the temperature measuring element 034 is arranged on the base plate 032 for measuring the temperature of the base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com