Laser shot peening device suitable for plate-shaped sample

A laser peening and strengthening device technology, which is applied in the field of laser shot peening strengthening devices for plate samples, can solve the problems of no protection device, high cost, and difficult control of the shot peening area, and achieve low cost, large reduction ratio, and transmission Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment, but protection scope of the present invention is not limited thereto:

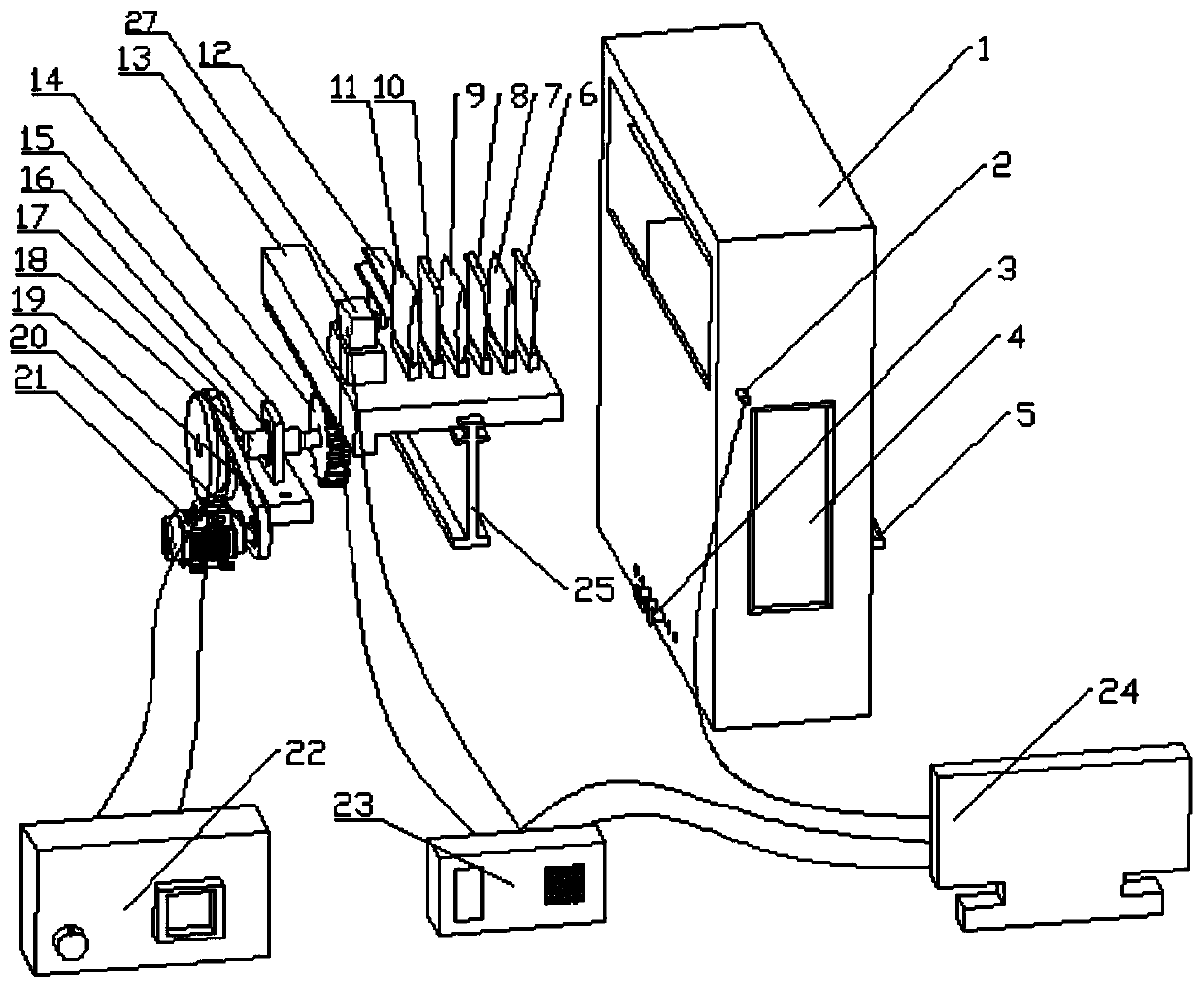

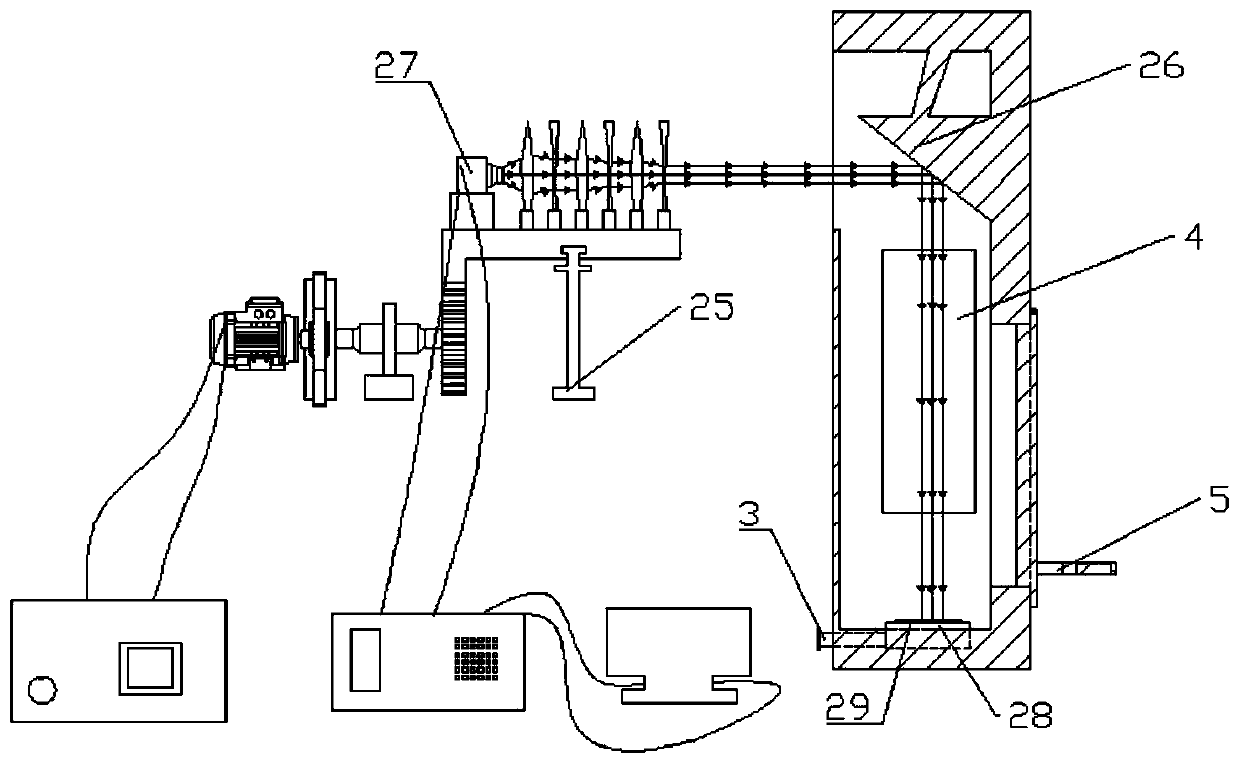

[0020] Referring to the accompanying drawings, a laser shot peening device suitable for plate-shaped samples includes a power device, a transmission device, a lens group device and a box device arranged in sequence along the transverse direction; the power device and the transmission device are arranged on the test bench, and the lens The group device is arranged on the transmission device, and the upper part of the box device is aligned with the lens group device;

[0021] Described power unit comprises motor 21, and the output shaft of motor 21 is connected with the input shaft of small pulley 20, and small pulley 20 is connected with large pulley 17 by belt 19, and the output shaft of large pulley 17 is connected with the left end of shaft 18 , the bearing support 15 supports the shaft 18 through the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com