Method for repairing damaged machinery component based on three-dimensional digitization

A technology for mechanical parts and repair methods, applied in the field of digital design solutions, can solve problems such as data information being unavailable, and achieve the effects of low measurement cost, strong operability, and easy editing and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

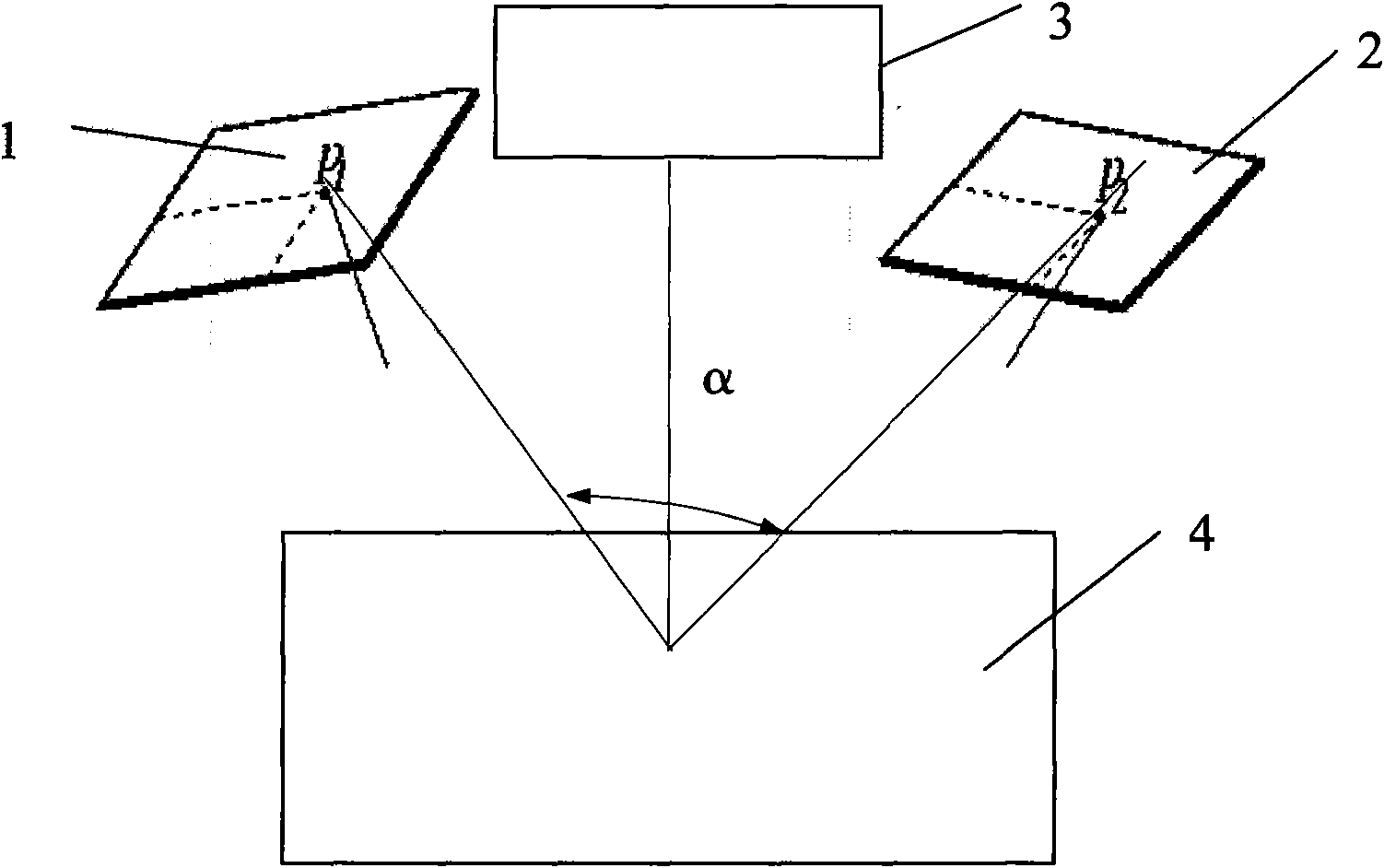

[0014] The hardware part of the present invention is composed of a laser measuring system for completing data measurement and a computer system for completing later data processing. like figure 1 , the laser measurement system to complete the data measurement is composed of two cameras 1, 2 and a grating projection device 3, and the two cameras 1, 2 form a certain angle α. The part 4 to be measured is placed on the lower part of the laser measurement system, and the three-dimensional coordinate point data on the surface of the part 4 to be measured is measured.

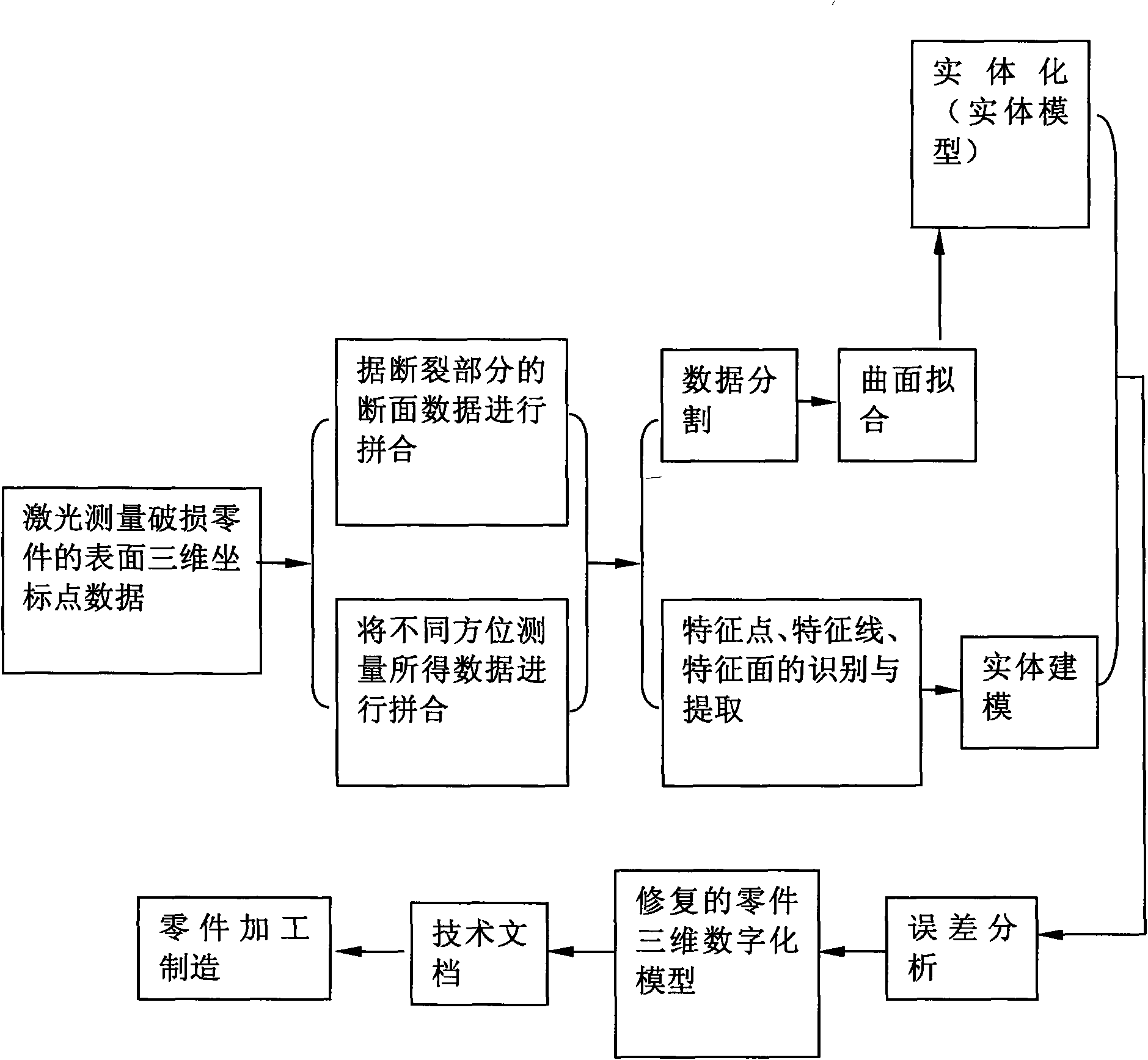

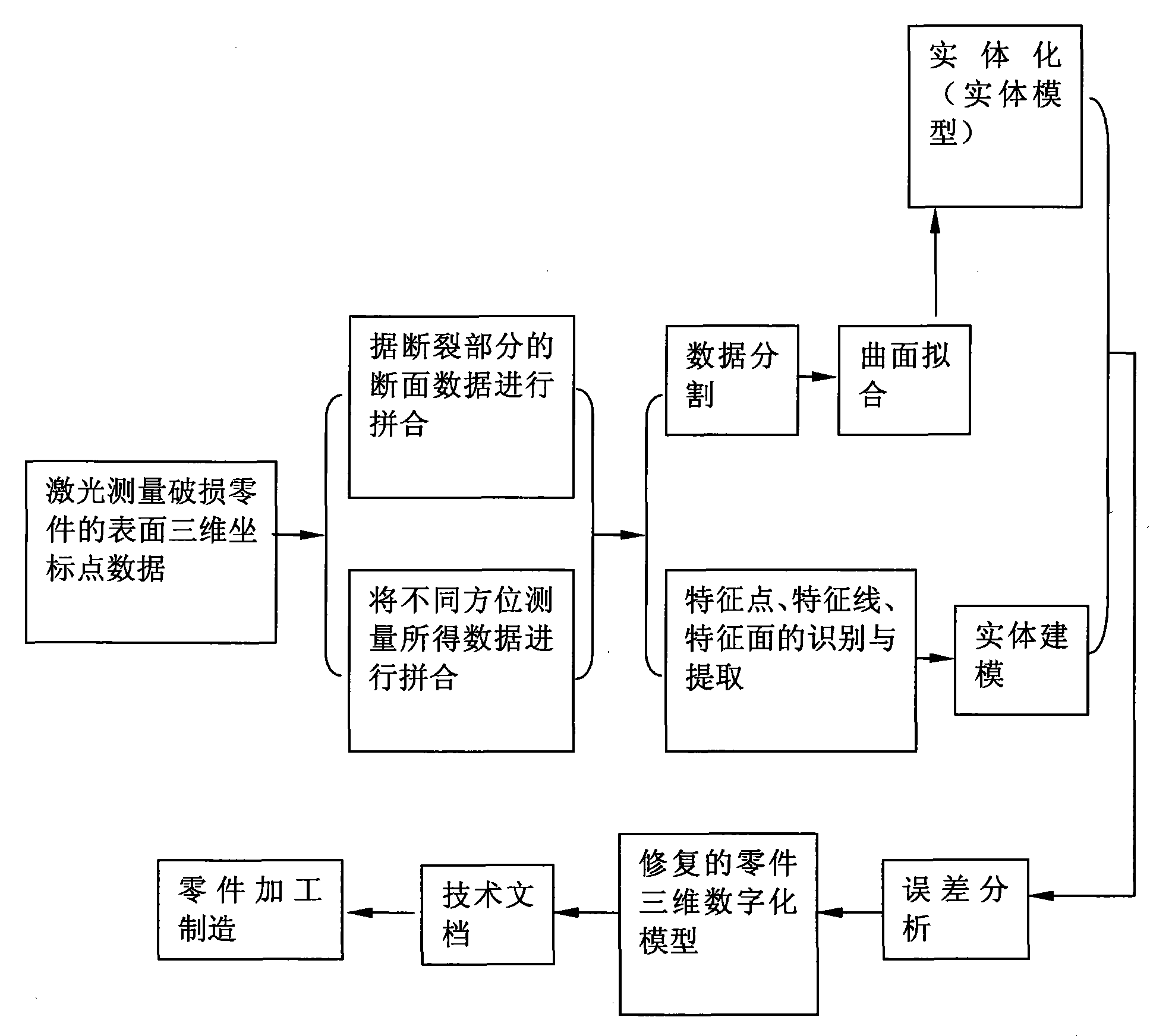

[0015] like figure 2 As shown, the present invention adopts the method of laser scanning to obtain the three-dimensional data points on the surface of the damaged part. According to the different properties of the part surface, the three-dimensional coordinate points on the surface of the part measured are used as the basis, using the feature recognition and extraction method, and combined with the three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com