Three-dimensional printing preparation method for upper dental crown of dental implant

A technology of three-dimensional printing and dental implants, which is applied in the field of denture processing, can solve the problems of affecting oral anastomosis, low work efficiency, and affecting final precision, and achieve the effects of avoiding waste of raw materials, high work efficiency, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

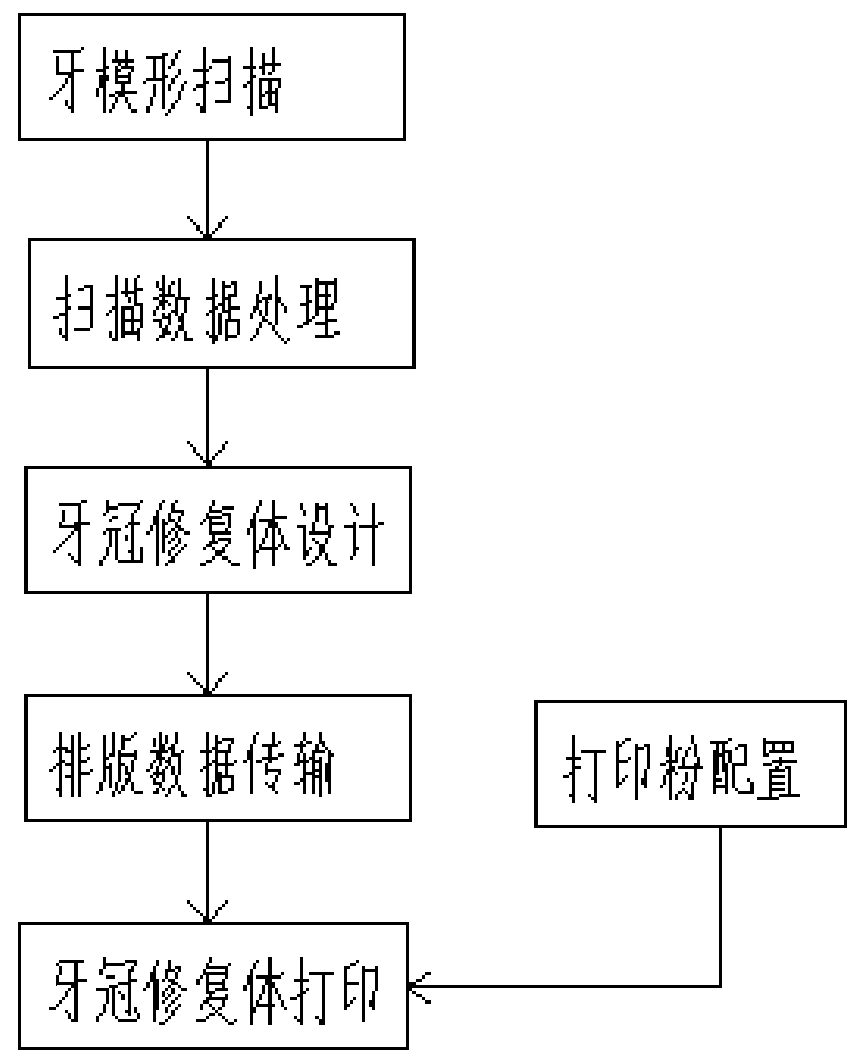

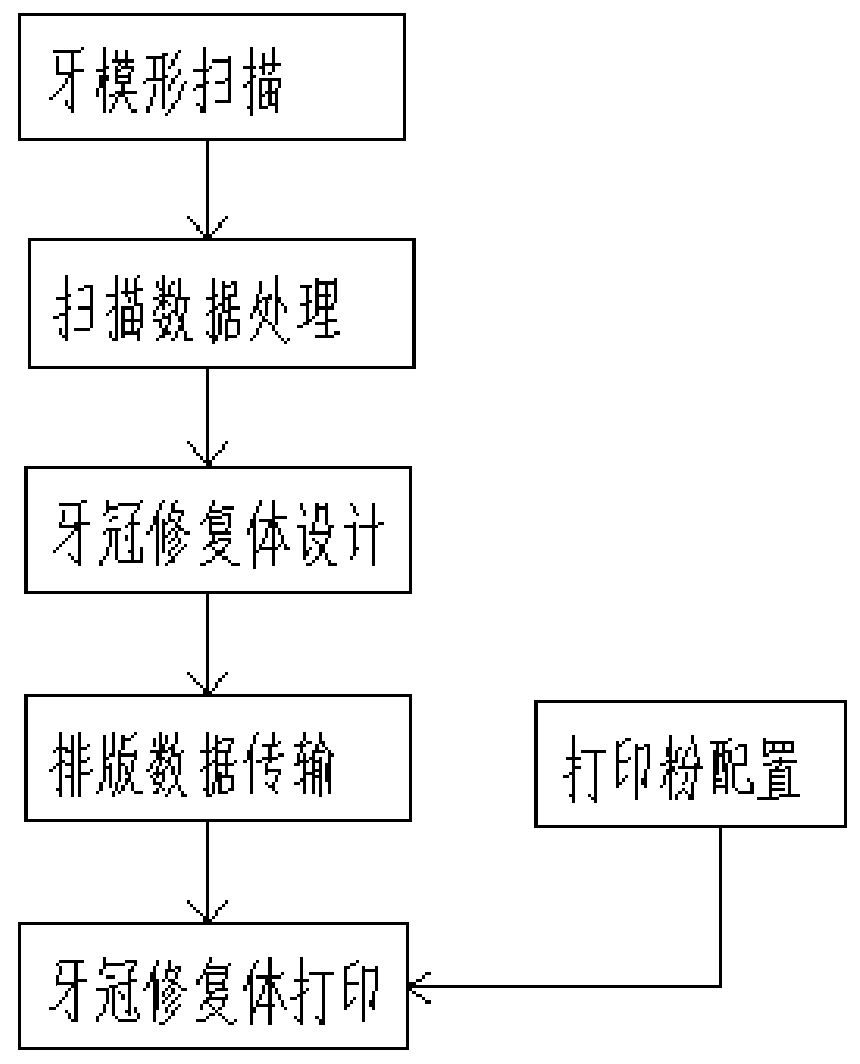

[0023] The three-dimensional printing preparation method for the crown of the upper part of the implant involved in this embodiment, the specific process includes dental model scanning, scanning data processing, crown restoration design, printing powder configuration, typesetting data transmission, and crown restoration printing Six steps:

[0024] (1) Dental mold shape scanning: use the existing technology to manufacture the plaster dental mold of the patient, computer-controlled optical scanner to scan the shape and size of the plaster model, collect the three-dimensional data of the optical impression of the plaster dental mold, and store the scanned data in the computer;

[0025] (2) Scanning data processing: using a computer system to process the three-dimensional data of the impression collected in step (1) and stored in the computer;

[0026] (3) Design of dental crown restorations: Design metal dental crowns by using the existing art implant software CAD installed in t...

Embodiment 2

[0034]The three-dimensional printing preparation method of the crown of the upper part of the implant involved in this example, its specific process is the same as the five steps in Example 1, and the components and proportions of the printing powder involved are as follows: albite, potassium feldspar, quartz, Talc powder, borax, sodium carbonate, potassium carbonate, sodium borate and cerium oxide, the printing powder is nano-scale fine particles, and the components of the porcelain tooth printing powder of selected color numbers are prepared and printed according to the following mass ratio: 25: 25:23:17:1:2:2:4.8:0.2, this ratio of printing powder is especially suitable for preparing posterior tooth crowns. The obtained posterior tooth crowns have a bending strength of 85MPa, a compressive strength of 800MPa, and a shrinkage rate of 0.5%, with high wear and corrosion resistance, beautiful appearance.

Embodiment 3

[0036] The three-dimensional printing preparation method of the crown of the upper part of the implant involved in this example, its specific process is the same as the five steps in Example 1, and the components and proportions of the printing powder involved are as follows: albite, potassium feldspar, quartz, Talc powder, borax, sodium carbonate, potassium carbonate, sodium borate, and cerium oxide, the printing powder is nano-scale fine particles, and the components of the porcelain tooth printing powder of selected color numbers are prepared according to the following mass ratios and printed: 26: 26:21:17:1:2:2:4.2:0.8, this ratio of printing powder is especially suitable for preparing incisor crowns. The prepared incisor crowns have a bending strength of 76MPa, a compressive strength of 720MPa, and a shrinkage 0.7%, with high wear resistance and corrosion resistance, beautiful appearance, bright color, milky white color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com