Field calibration and precision measurement method for spot laser measuring system

A measurement system and field calibration technology, applied in measurement devices, optical devices, image data processing, etc., can solve the problems of harsh calibration conditions and complicated calibration steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

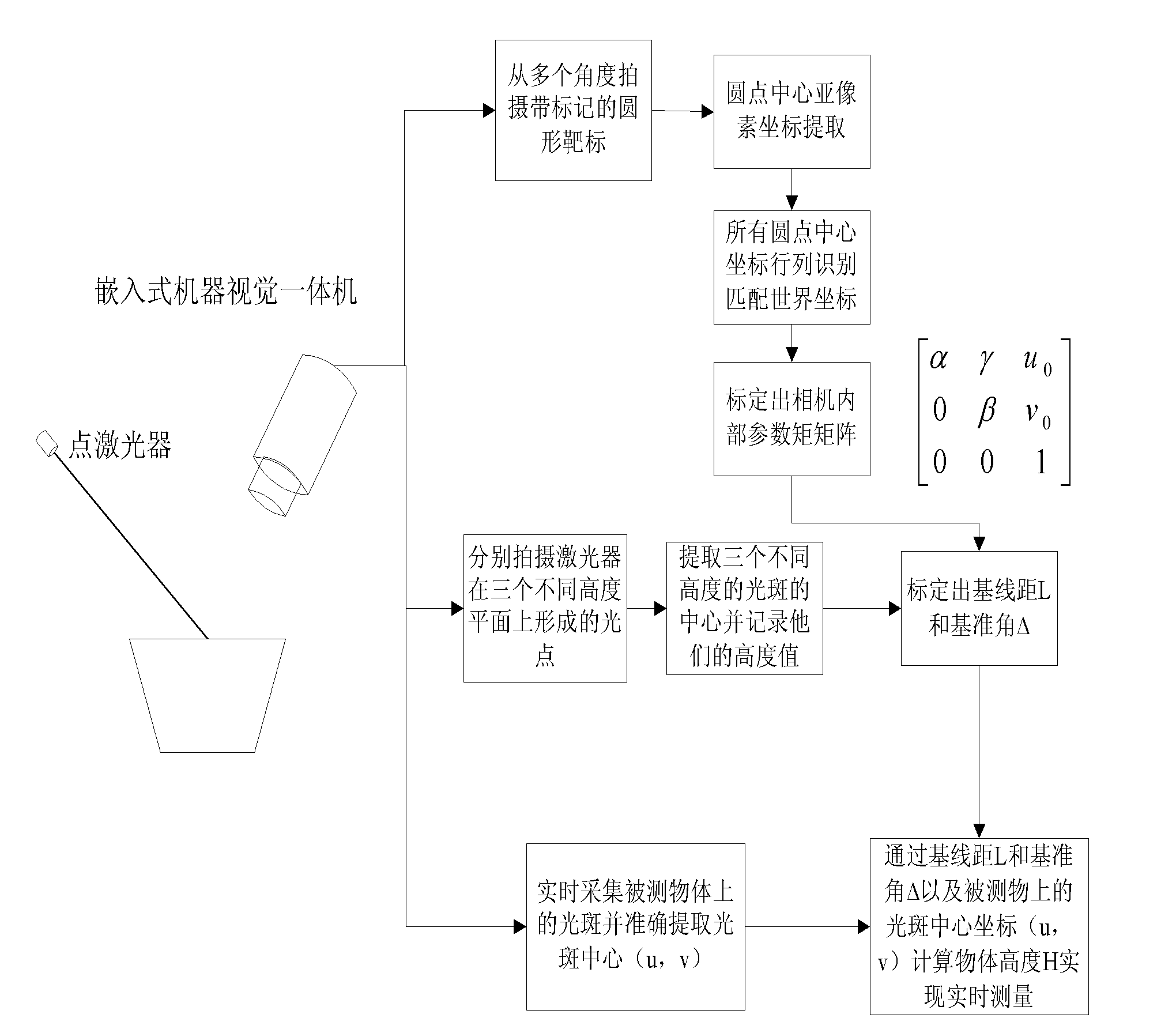

[0044] In order to improve the flexibility and practicability of the laser measurement system and improve the measurement accuracy, the invention develops a calibration technology. The calibration technology algorithm has small code size, fast operation speed, high precision, strong real-time performance, and good stability. It can improve the disadvantages of traditional measurement, reduce costs, and increase production speed.

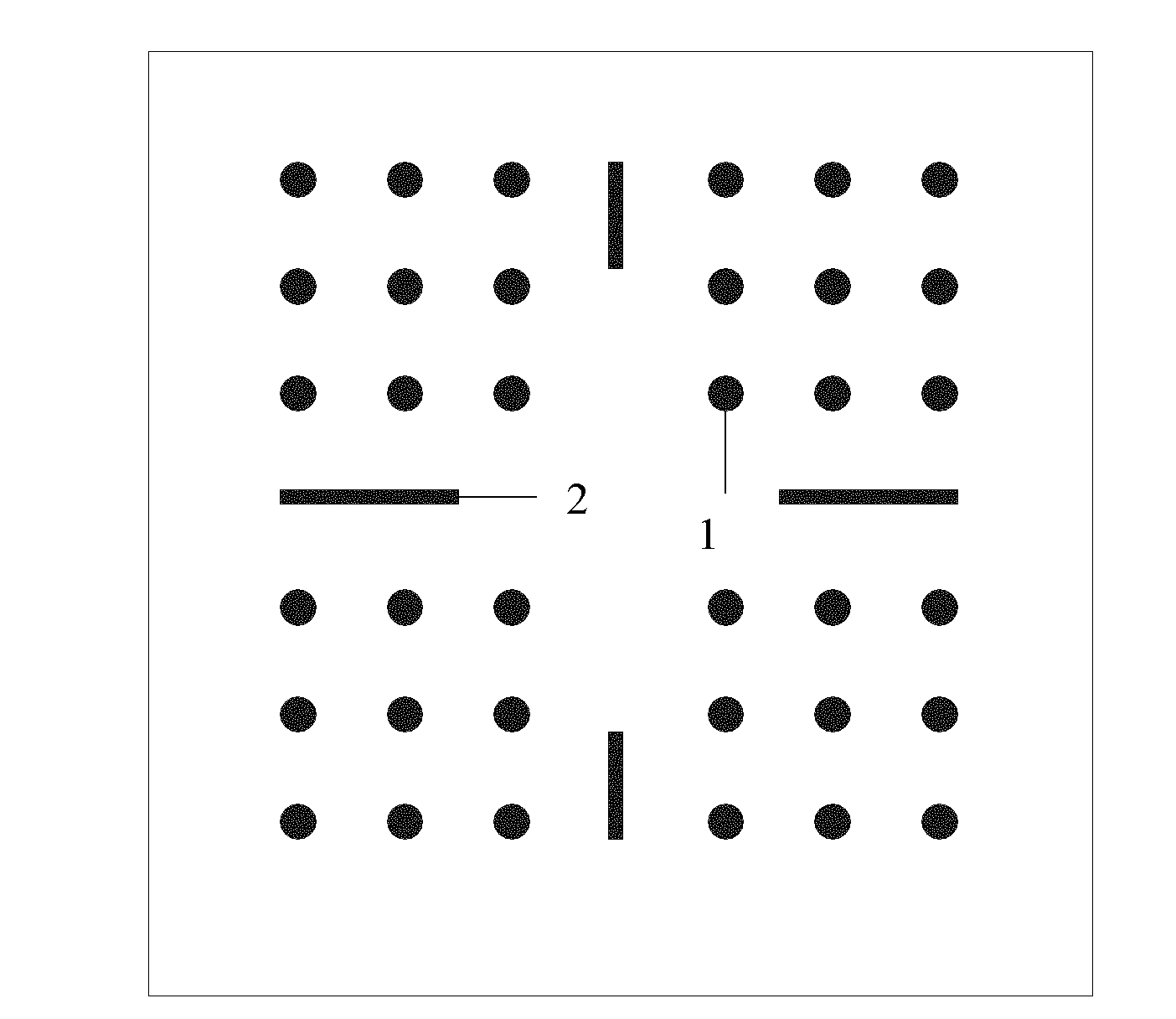

[0045] The present invention utilizes as image 3 The marked circular target shown, including dot 1 and marking strip 2, can realize fast positioning of corner points, automatically realize the recognition of rows and columns of corner points, and automatically match the world coordinates and pixel coordinates of corner points, which is beneficial to the camera Automated parameter calibration; analyze the mathematical model of the laser-camera measurement system, introduce the concepts of baseline distance and reference angle, and only need to shoot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com