Vision guiding tunnel sign point coordinate laser measurement system and method

A laser measurement system and vision-guided technology, applied in measuring devices, surveying and navigation, and optical devices, to achieve fast measurement, simple structure, and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

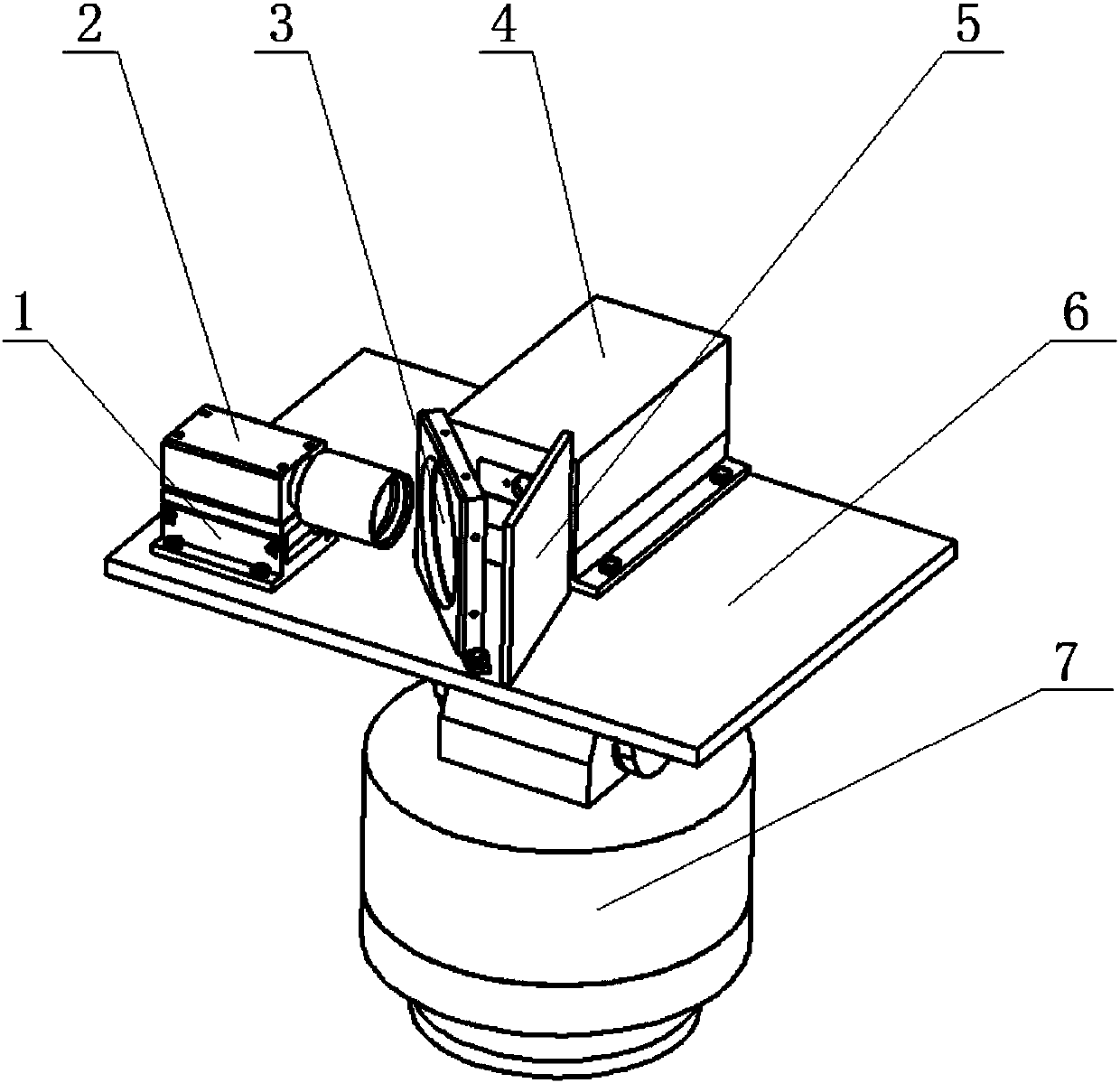

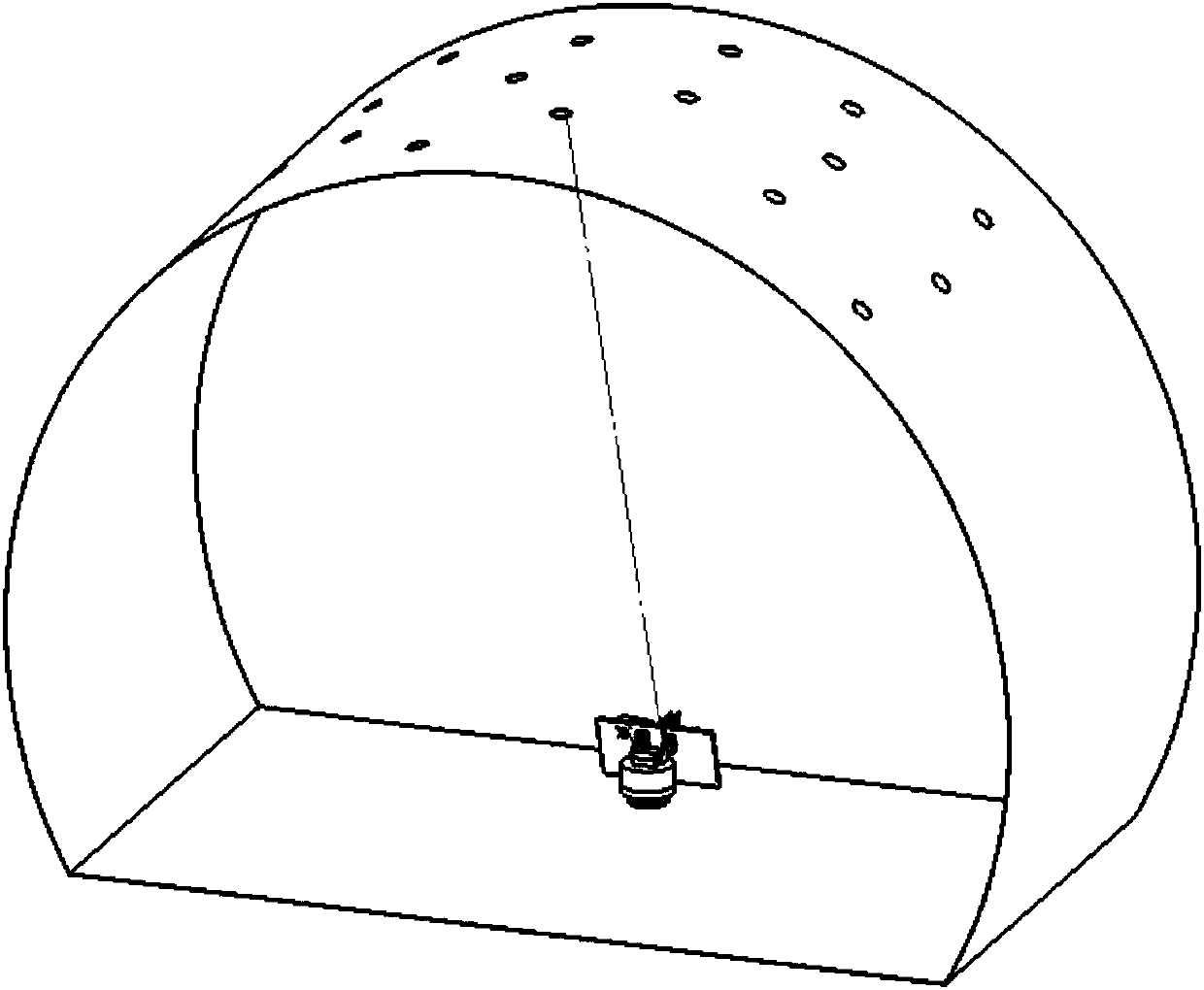

[0027] The specific implementation of the invention includes marking points arranged on the rock wall of the tunnel, a visible light lamp irradiated on the rock wall of the tunnel and a coordinate measuring device for the marking points. Such as figure 1 As shown, the marker point coordinate measuring device includes a camera mounting table 1 for adjusting the pose of the industrial camera, an industrial camera 2 for assisting laser aiming, a narrow-band filter 3 for reflecting visible light through the laser, and a The laser displacement sensor 4 for the distance from the point to the measuring device, the shading plate 5 for absorbing part of the laser light and blocking the ambient light, the mounting plate 6 for connecting the pan / tilt and other components, and driving the measuring device for horizontal rotation and vertical pitch Sports gimbal 7;

[0028] The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com