Antifriction bearing for a steering column

An anti-wear, bearing technology, applied in the direction of rotating bearings, steering columns, bearings, etc., can solve problems such as high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

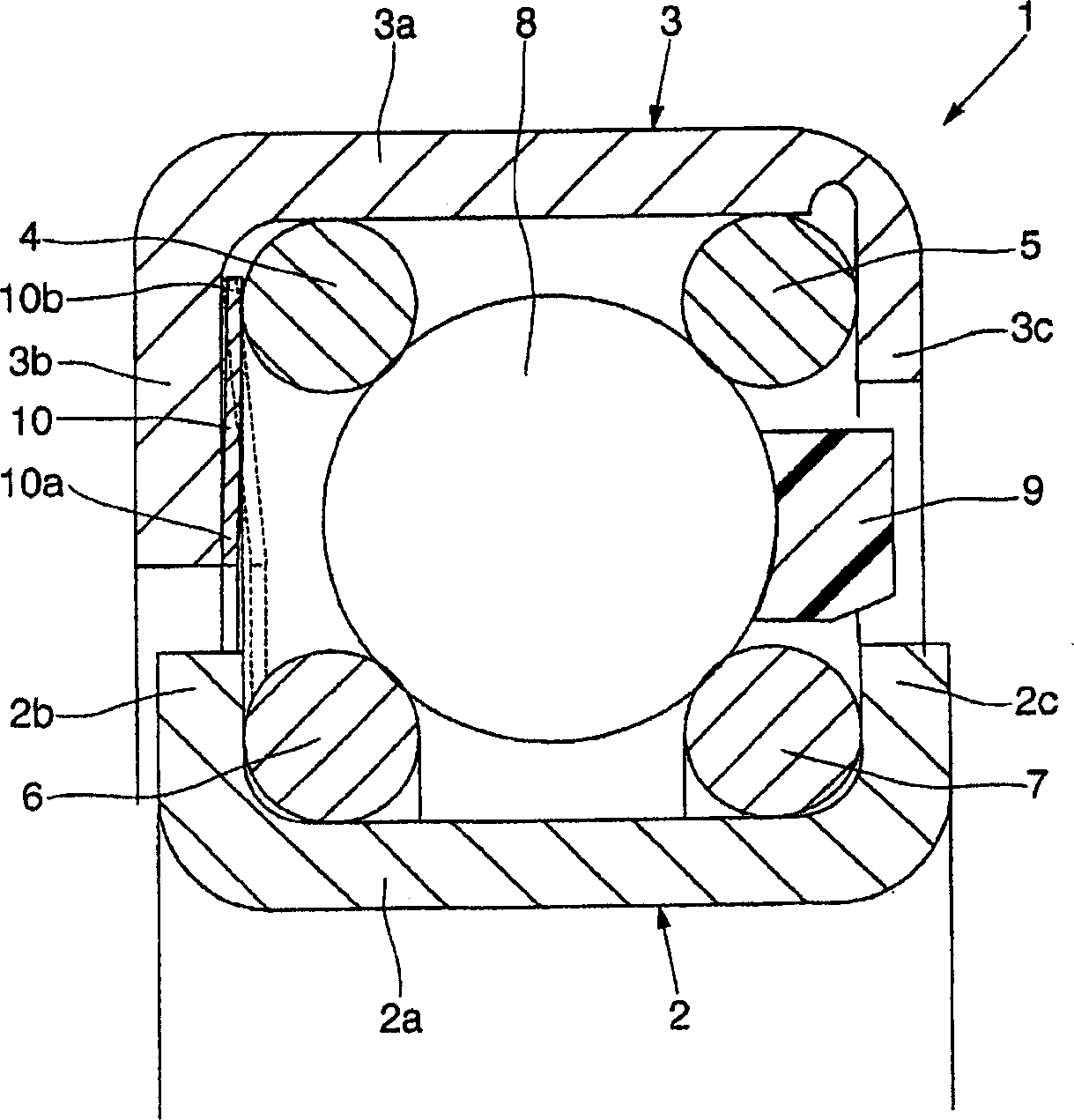

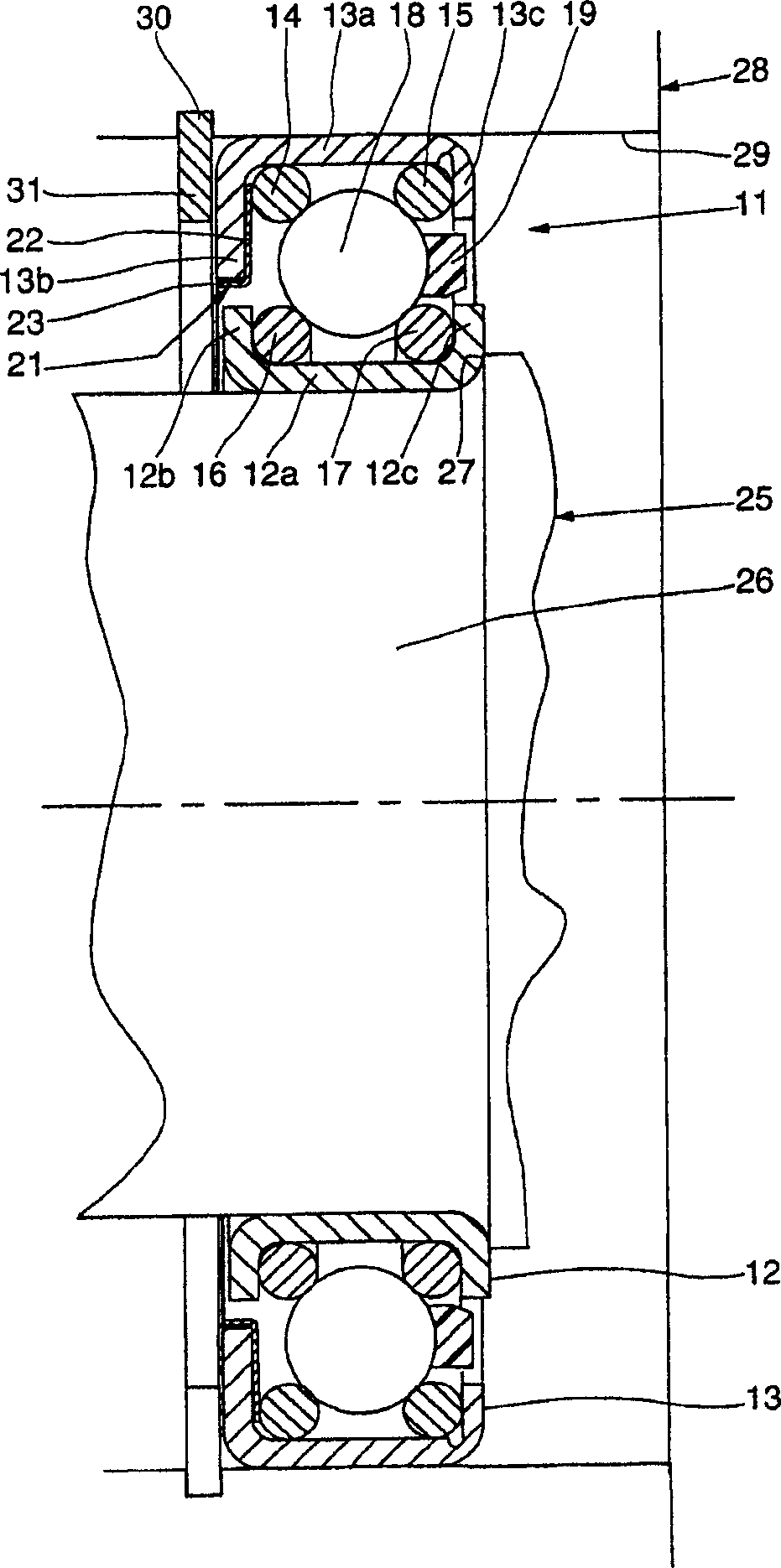

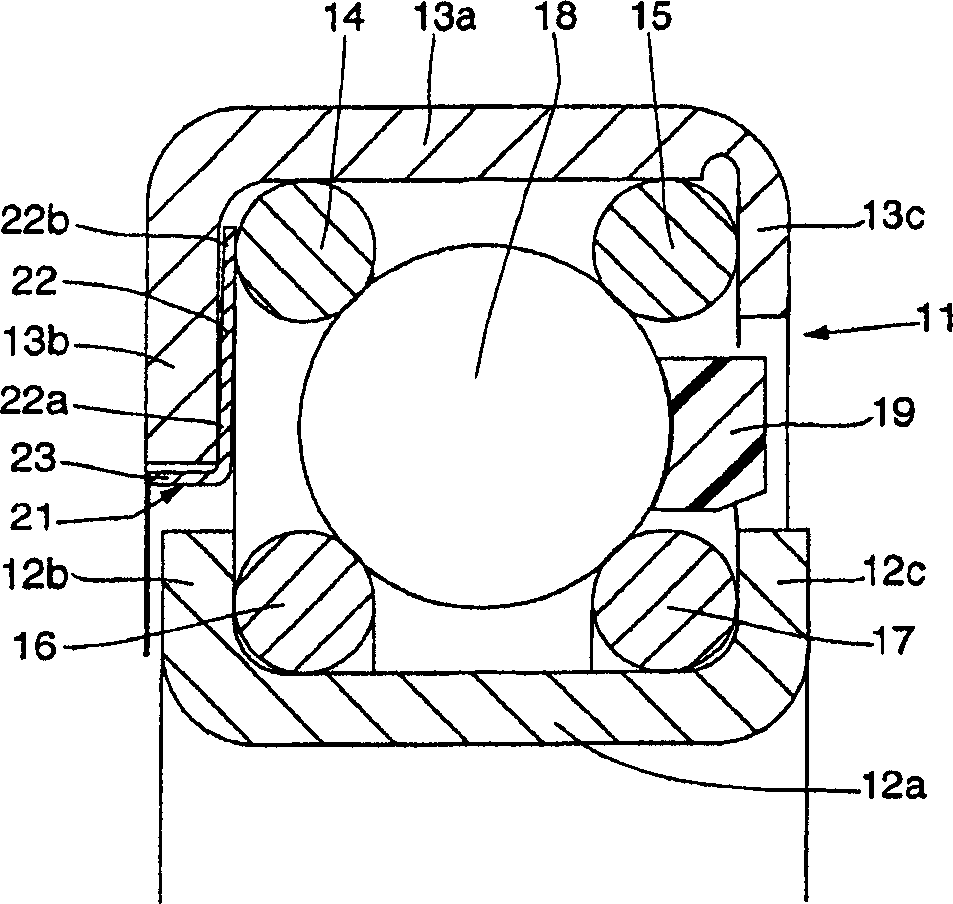

[0032] Such as figure 1 As shown, a bearing 1 includes an inner sheath 2 , an outer sheath 3 , four wires 4 , 5 , 6 and 7 , a row of rolling elements 8 , a cage 9 and a Belleville washer 10 . The inner ring 2 comprises an axial portion 2a extending at each of its axial ends with radial portions 2b, 2c. The radial sections 2b and 2c are identical. The inner sheath 2 thus exhibits a ring shape with a U-shaped cross-section.

[0033] The outer sheath 3 also has a ring of U-shaped cross-section and an axial portion 3a, a radial wall 3b and a radial wall 3c. The thickness of the radial wall 3c is smaller than the thickness of the axial portion 3a and the thickness of the radial portion 3b, and the length in the radial direction is smaller than the length of the radial portion 3b. In other words, the interval separating the radial portions 2c and 3c is greater than the interval separating the radial portions 2b and 3b.

[0034] Wires 4 and 5 are arranged in an outer sheath, whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com