Assembly tool for low-pressure turbine of engine

A low-pressure turbine and assembly tooling technology, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problem of loss of bearings, etc., and achieve the effects of improved positioning accuracy, simple structure, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

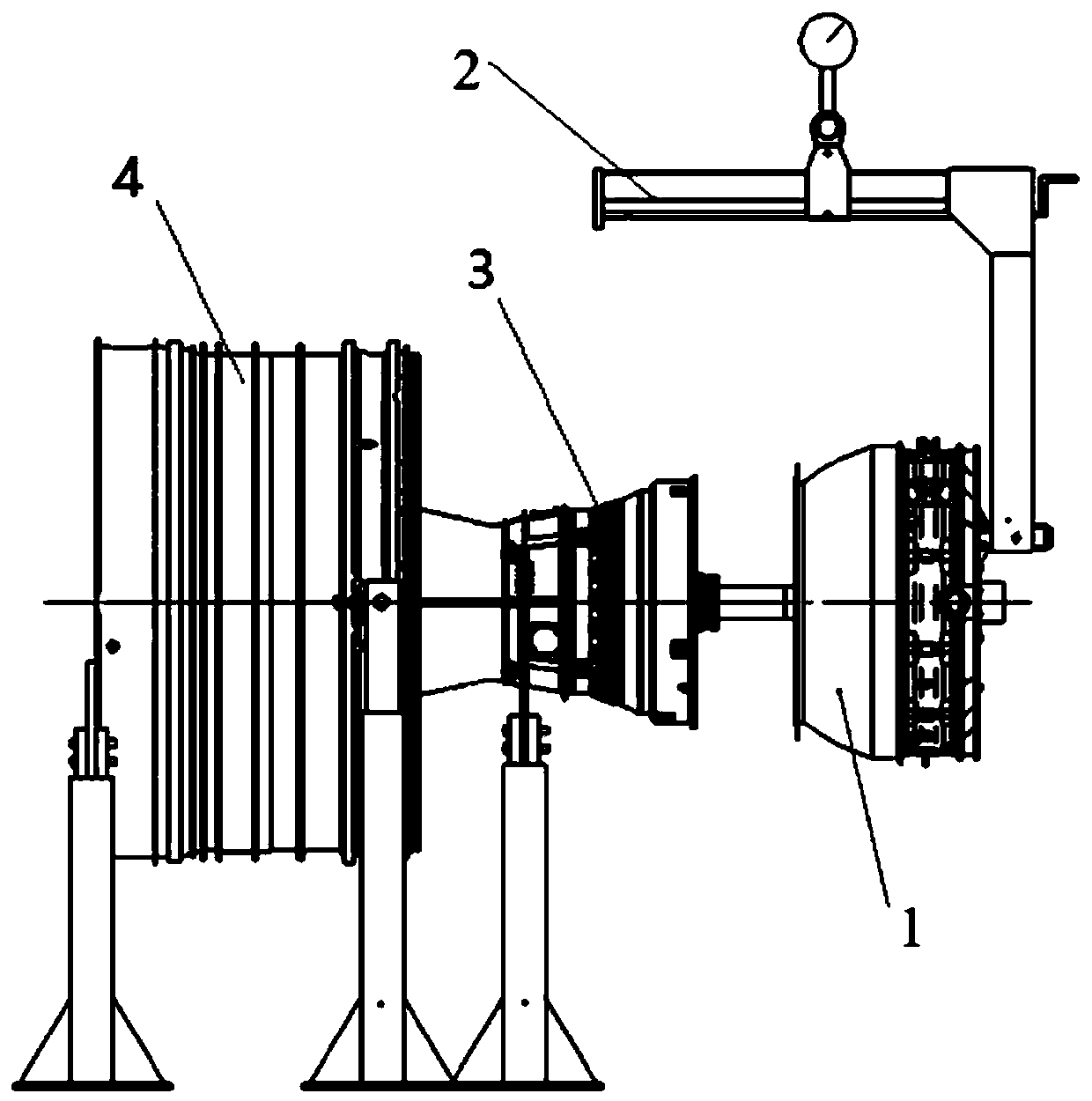

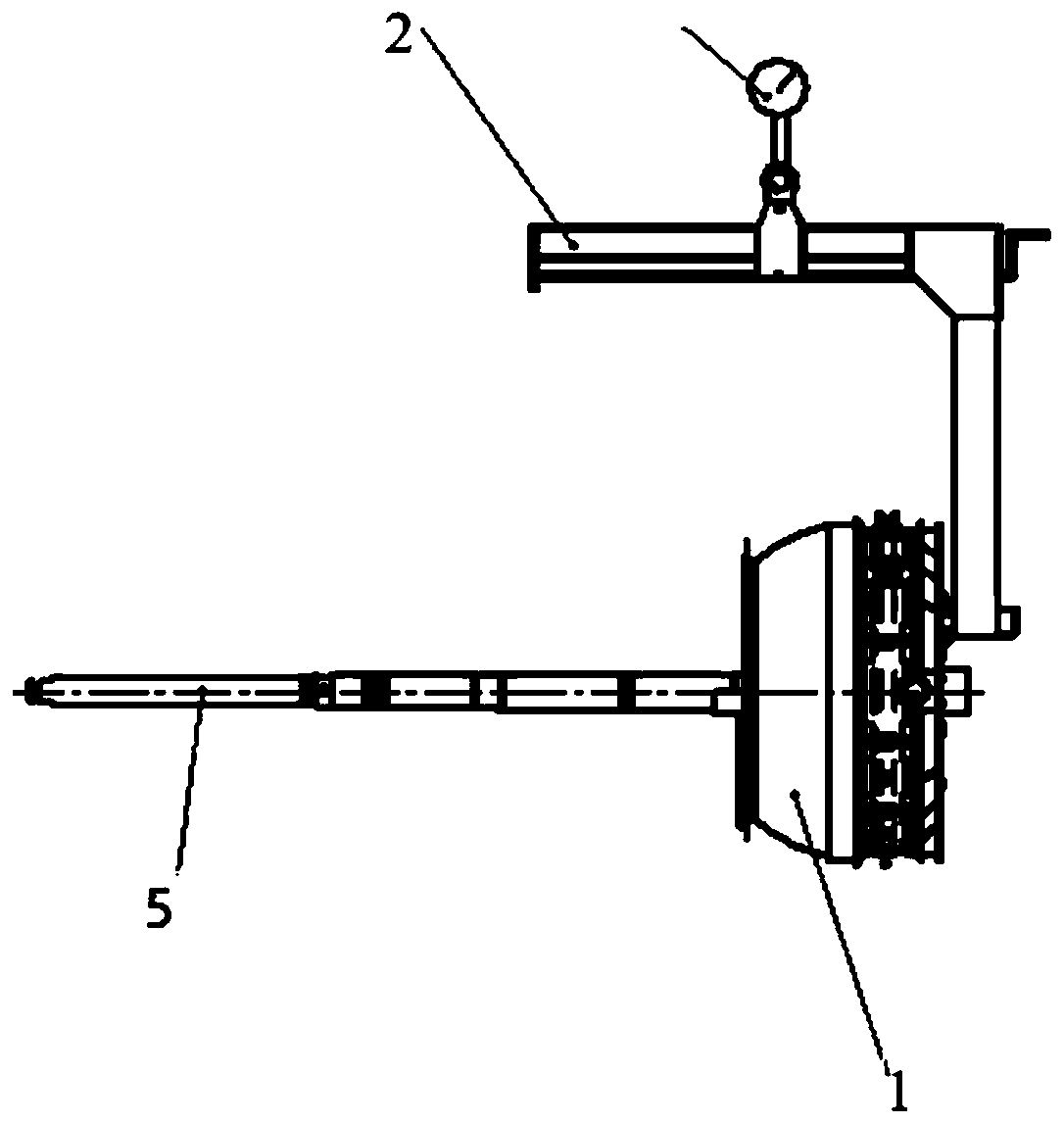

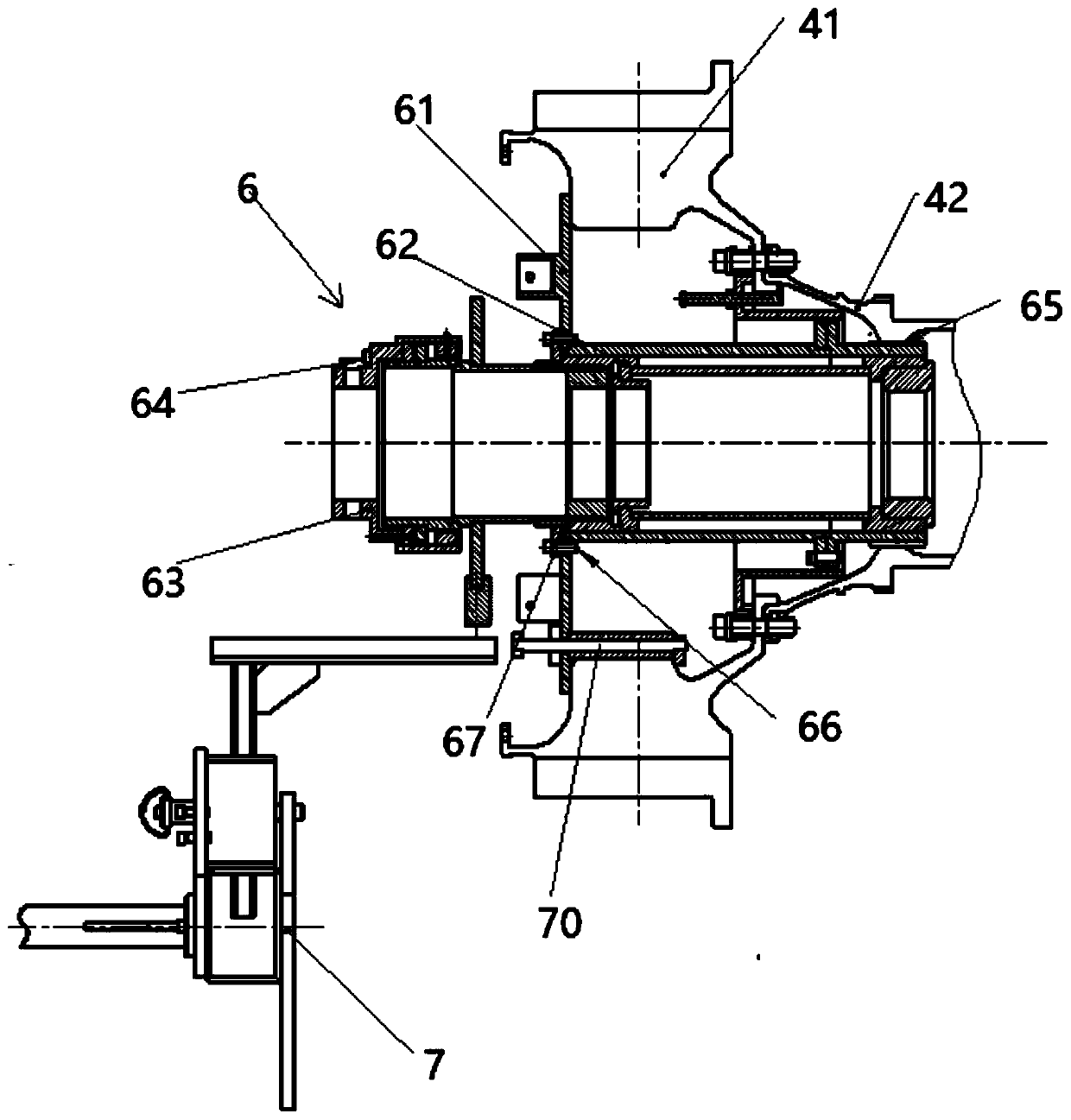

[0048] refer to Figure 1-11 , an assembly tool for a low-pressure turbine of an engine, including a positioning guide tool 5, a traction tool 6 and a torque multiplier 9.

[0049] The positioning guide tool 5 is coaxially connected with the low-pressure turbine shaft of the low-pressure turbine 1, the traction tool 6 is installed on the fan rotor 4, and the positioning guide tool 5 passes through the core machine 3 and the axis of the fan rotor 4 and is connected to the torque multiplier 9.

[0050] The positioning guide tool 5 includes a positioning shaft 51 , a traction shaft 52 , an adjustment shaft 57 and an adjustment rod 58 .

[0051] The traction shaft 52 and the positioning shaft 51 are both hollow shafts, one end of the positioning shaft 51 is embedded in one end of the tracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com