Self-locking cantilever beam, bearing device and operation platform

A bearing device and operating platform technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of difficulty and risk of installation or disassembly, achieve convenient disassembly, improve stability, and enhance stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

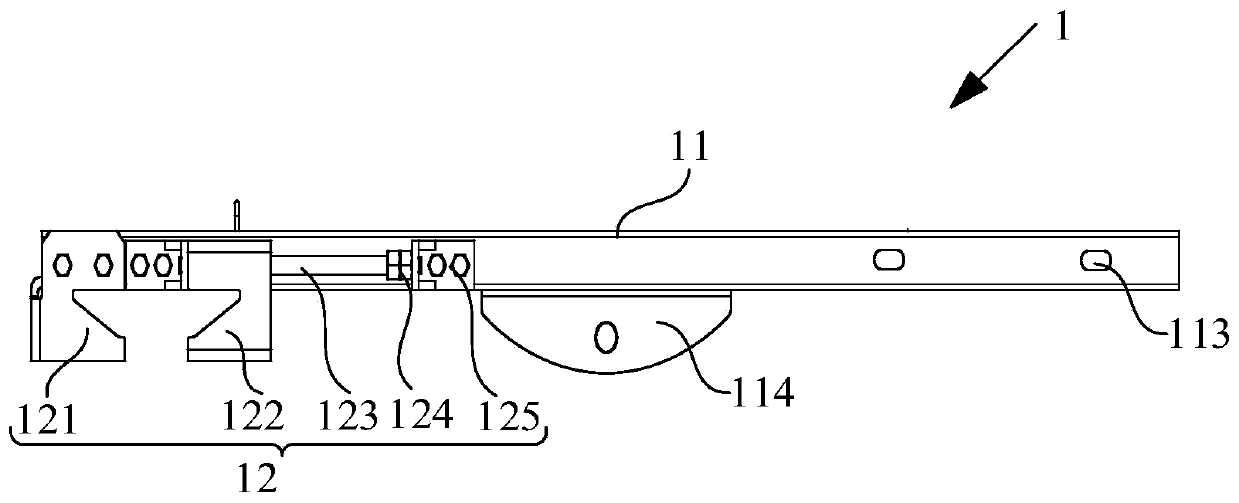

[0043]The application provides a self-locking cantilever beam, including a beam and a clamping assembly arranged at one end of the beam; the clamping assembly includes a first clamping piece, a second clamping piece, a connecting rod and a locking piece, the first The clamping part is arranged at one end of the beam, the two ends of the connecting rod are connected to the beam, and the second clamping part is passed through the connecting rod; the second clamping part can move toward or away from the first clamping part, so that at the A clamping space whose range can be adjusted is formed between the first clamping part and the second clamping part; when the second clamping part moves to a predetermined position, the locking part can lock and limit the displacement of the second clamping part.

[0044] Wherein, it should be noted that the locking of the locking member and restricting the displacement of the second clamping member may include, for example, two situations. The f...

Embodiment 2

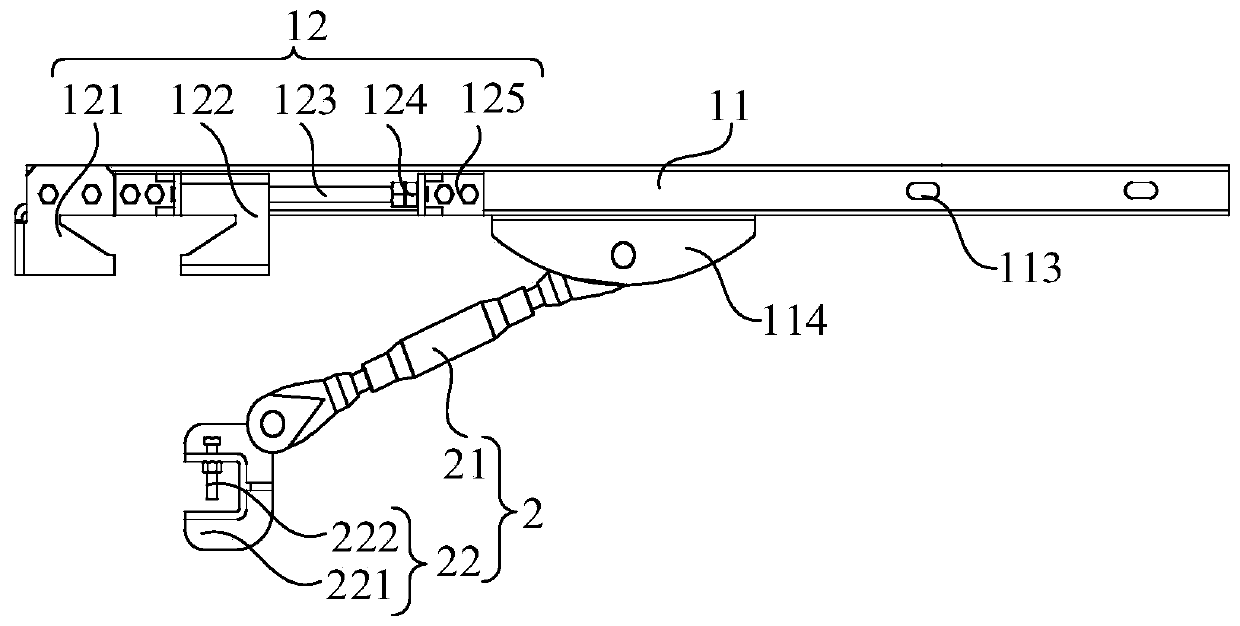

[0053] Such as Figure 1 to Figure 5 As shown, the embodiment of the present application provides a carrying device, including the support 2 and the self-locking cantilever beam 1 in the first embodiment; since the self-locking cantilever beam 1 has the technical effect in the first embodiment, so The carrying device with the self-locking cantilever beam 1 also has the same technical effect, and further the same structural features will not be repeated one by one.

[0054] The support member 2 includes a telescopic rod 21 and a third clamping member 22 , one end of the telescopic rod 21 is hinged to the center of the lower abdomen of the beam 11 , and the other end is hinged to the third clamping member 22 .

[0055] Such as image 3 As shown, one end of the telescopic rod 21 is hinged to the mount 114 on the beam 11 , and the other end is hinged to the third clamping member 22 , which is used to clamp other components.

[0056] The structure of telescopic rod 21 is as Fig...

Embodiment 3

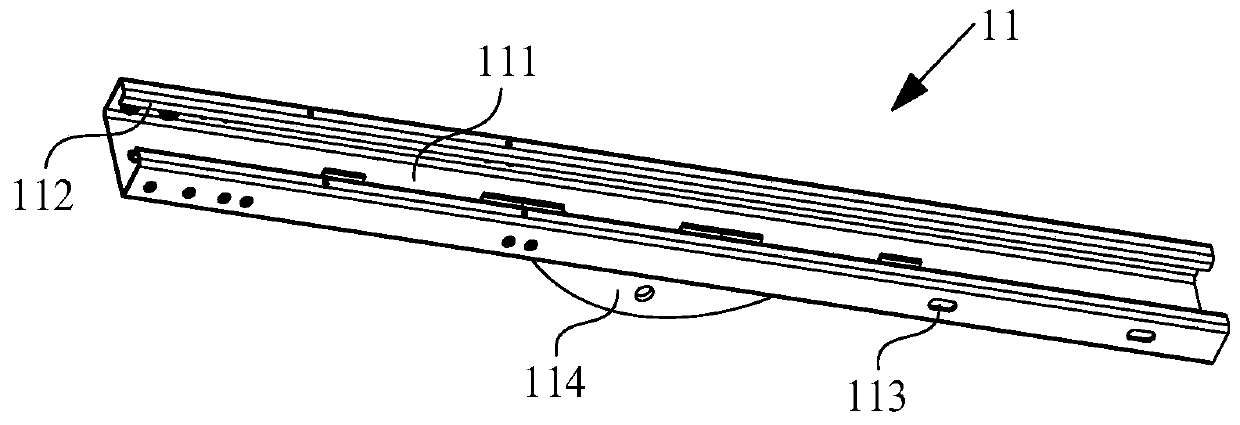

[0060] Such as Figure 1 to Figure 8 As shown, the embodiment of the present application provides a working platform, including a platform board 3 and at least two carrying devices in the second embodiment. Since the carrying device has the technical effect in the second embodiment, the working platform with the carrying device It also has the same technical effect, and then the same structural features will not be repeated one by one; the bearing devices are arranged at intervals, and the platform board 3 is provided with an anti-detachment hook, which can slide into the long groove 111 of the crossbeam 11 and can be connected with the hem 112 are hooked so that the platform board 3 is installed on every two adjacent carrying devices.

[0061] Such as Figure 6 As shown, the platform board 3 is used for people to walk and stand. The two ends of the platform board 3 have anti-detachment hooks. When installing, the anti-detachment hooks slide into the long groove 111 of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com