Patents

Literature

72results about How to "Assembly positioning is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

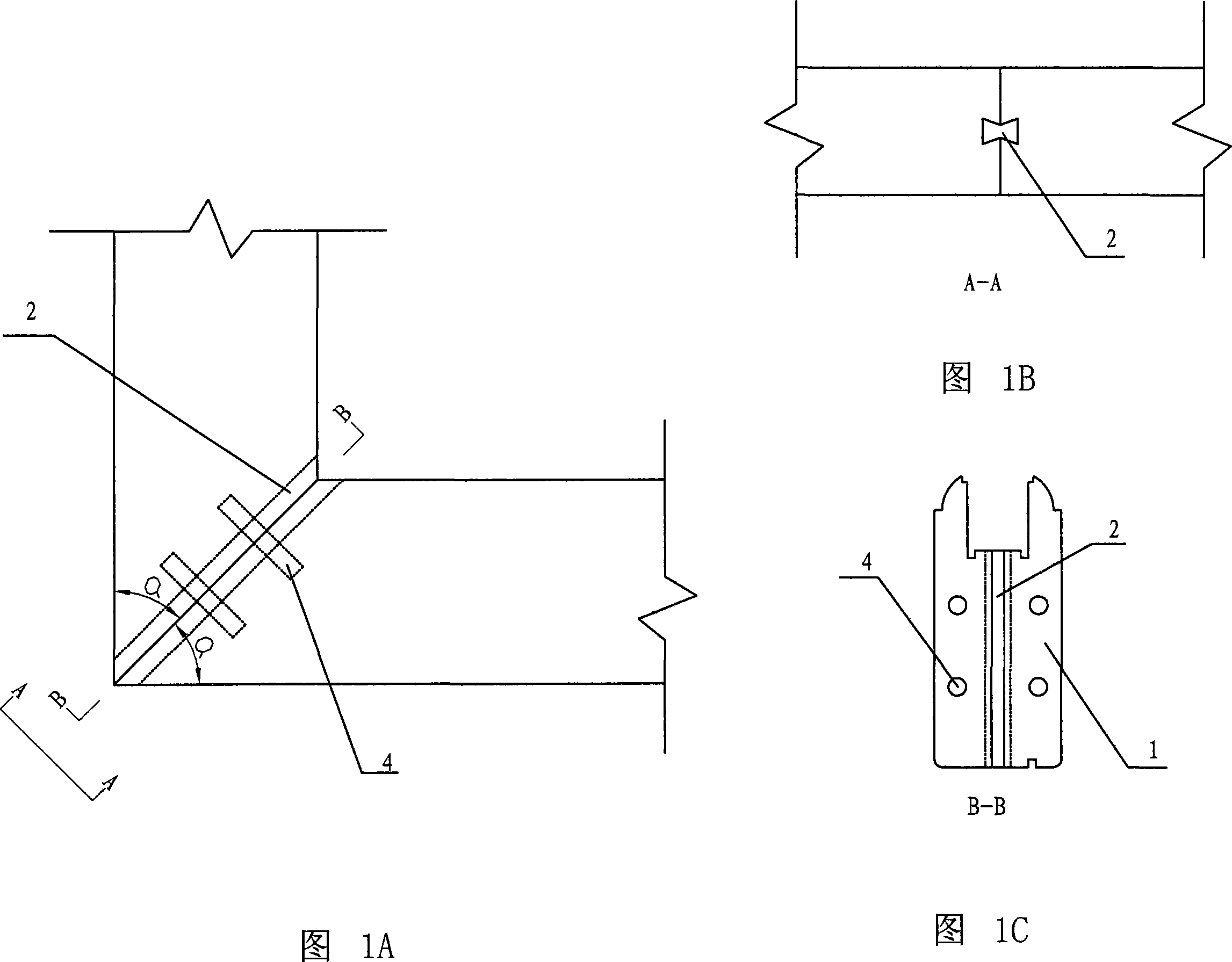

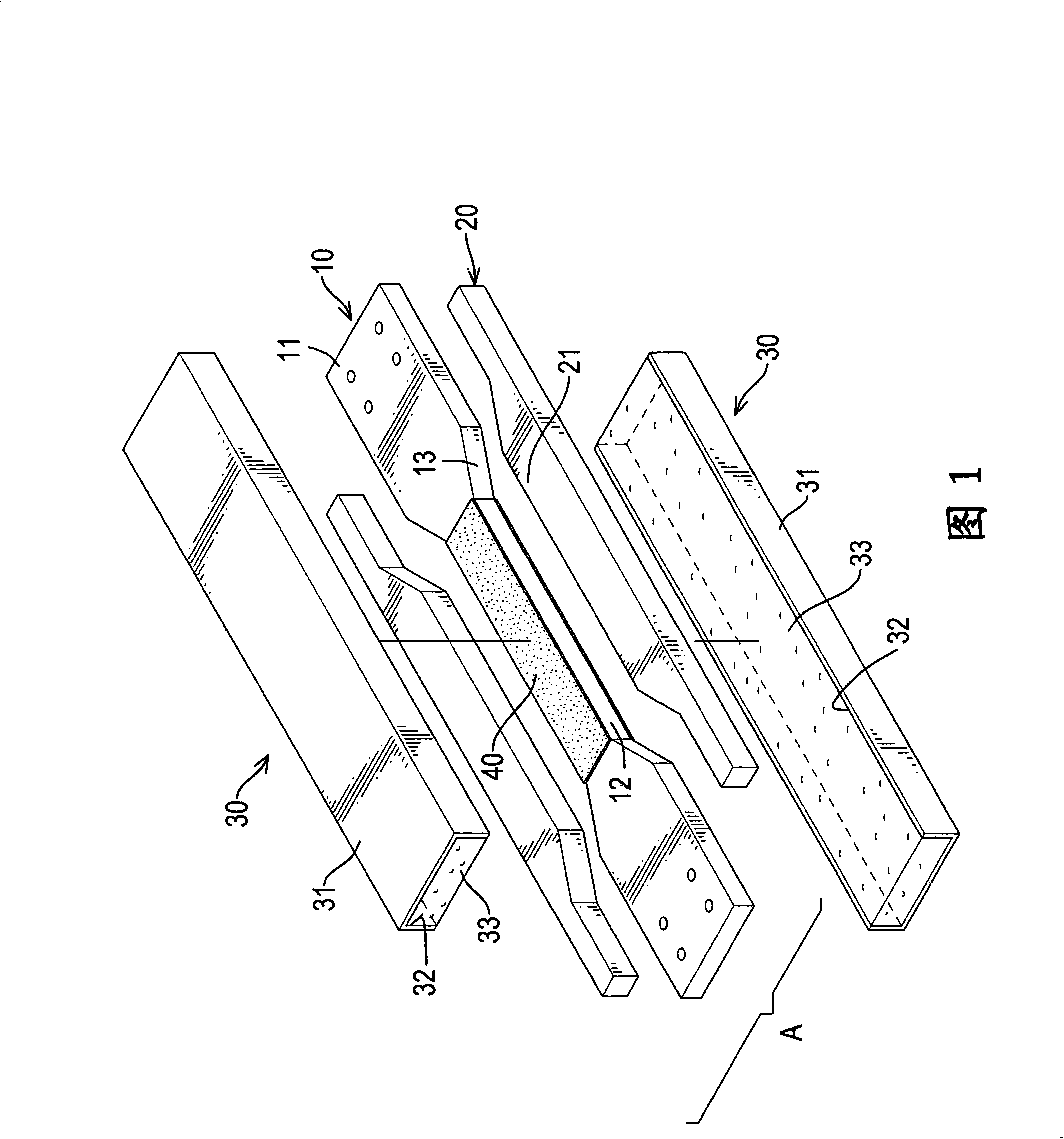

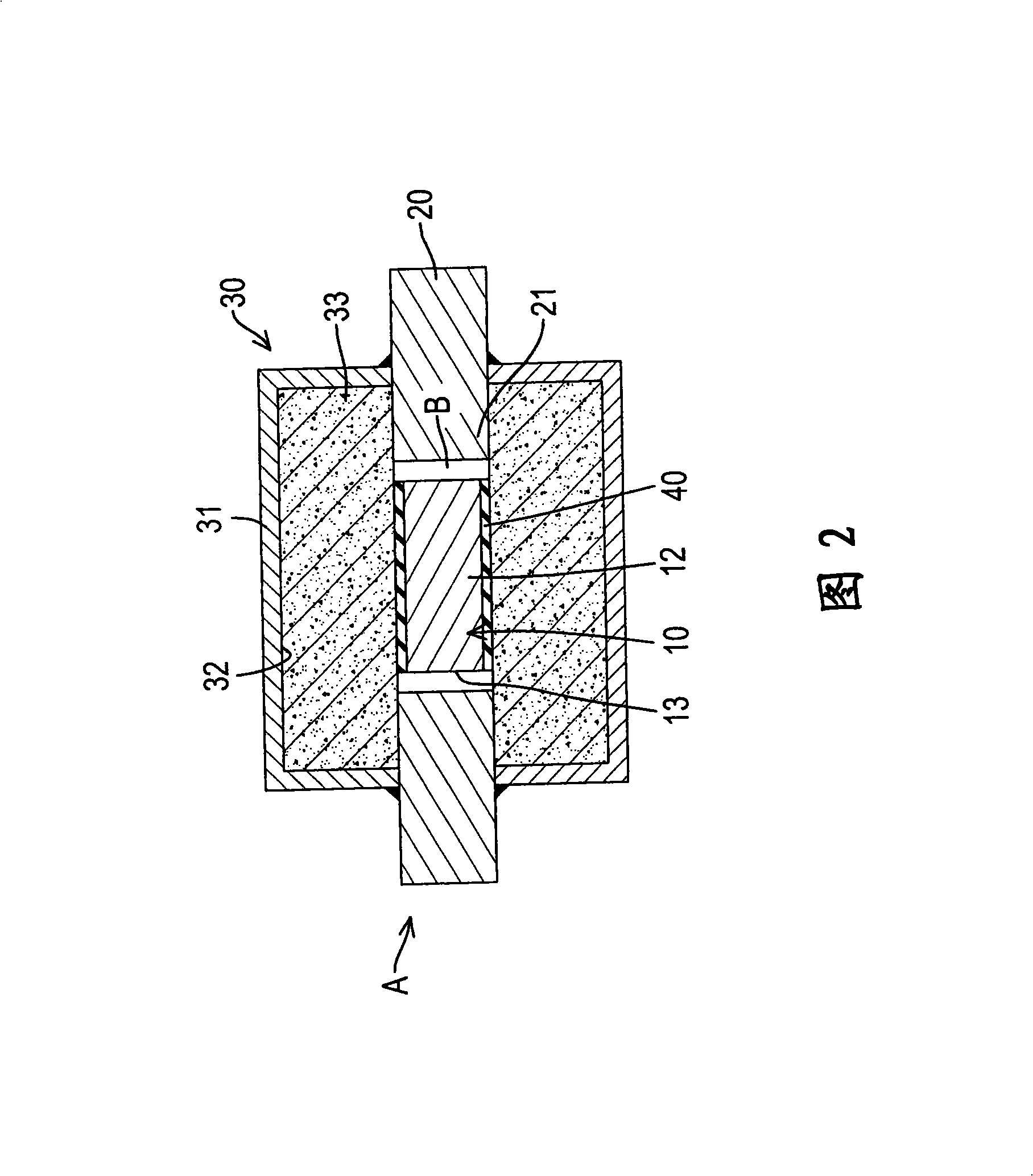

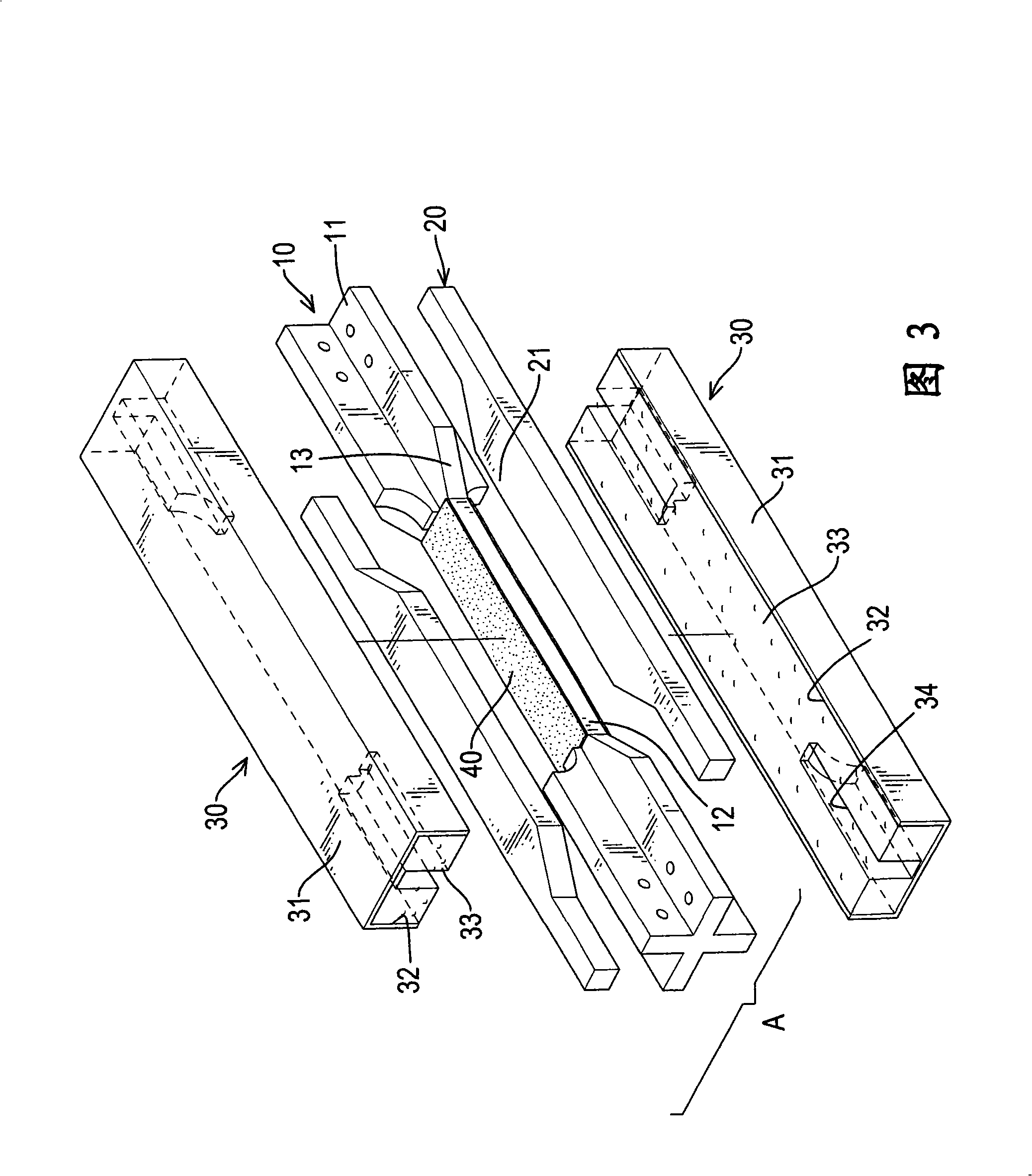

Method for manufacturing wooden sash section bar and method for assembling wooden window and door by using the same

InactiveCN101117874AImprove connection strengthReduce connection strengthCorner/edge jointsWindow/door framesEngineeringBuilding construction

A manufacturing method for assembling wood and door frame section material in field comprises the following steps: firstly, the wood is cut as per specified size and section shape; secondly, after cut, combination surfaces are formed on both ends of the wood, a key channel is formed at the combination surface, after the key channel is assembled into a frame parallel to the wood door section material and extended at the plane where is located and arranged between two surfaces of the frame, after the wood door and the window section material are matched at the corresponding combination surfaces, a pin key lock is used to fix with the adaptive key channel shapes; thirdly, surface treatment is done for wood of all the formed combination surfaces and key channels to be applicable for the wood door and the window section material for assembly at the construction site. The present invention is applicable for the manufacturing method for the wood door and the window section material in field and the method for assembling the wood door and the window with the section material for on-site arrangement. Structural strength of tenon is high, thus not damaging the surface of the section material and keeping the door and the window nice.

Owner:北京市木材厂有限责任公司

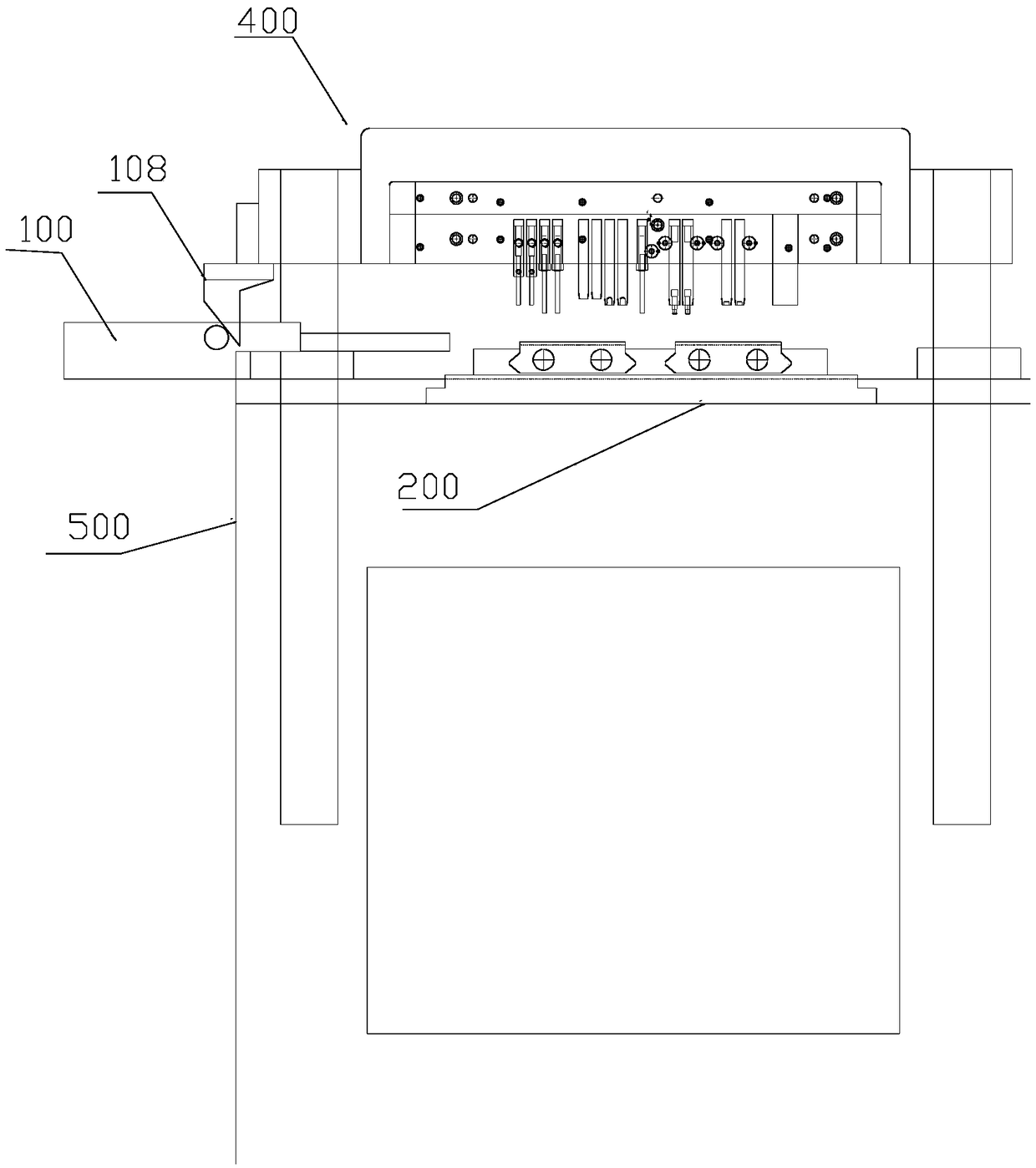

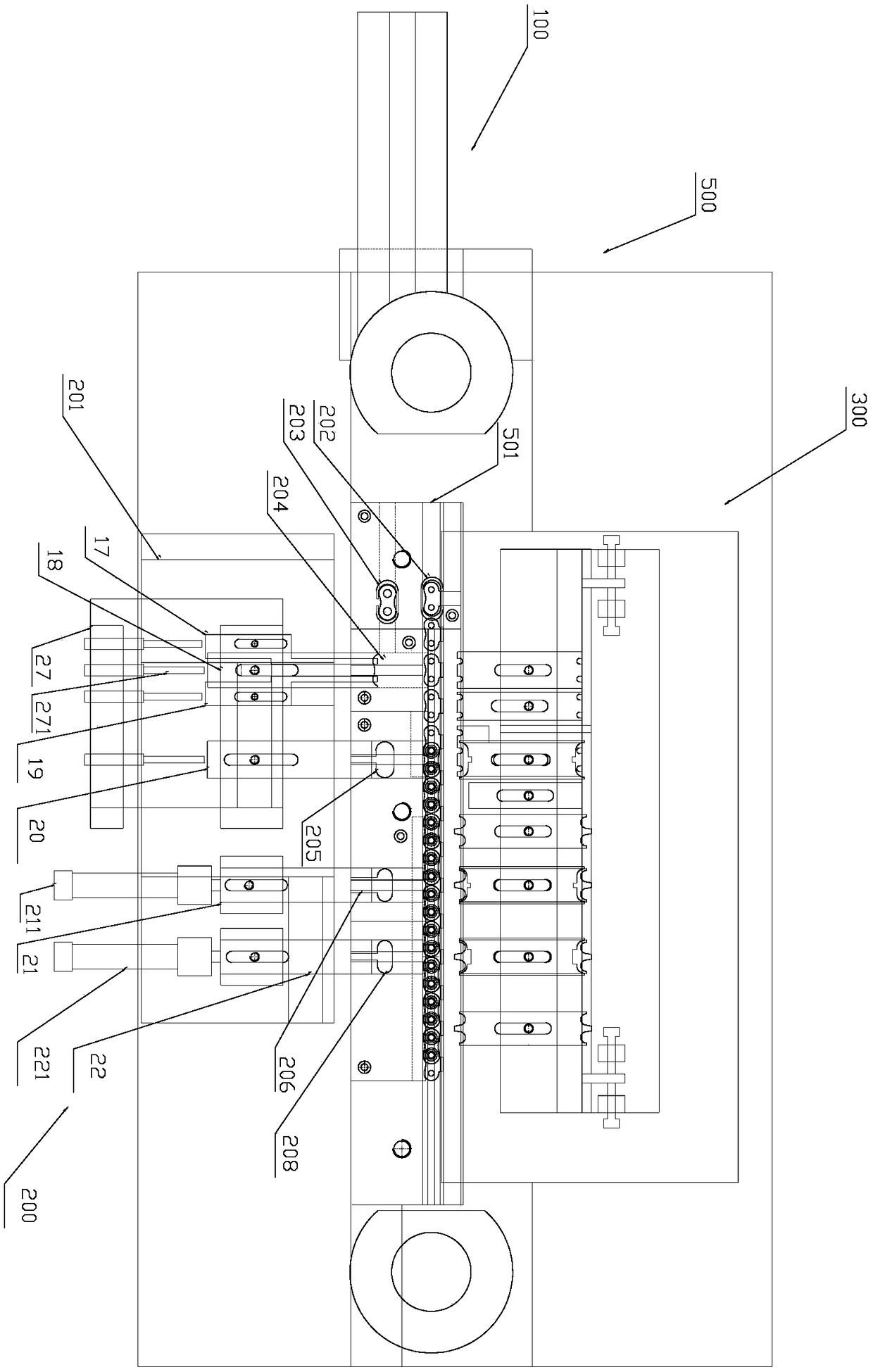

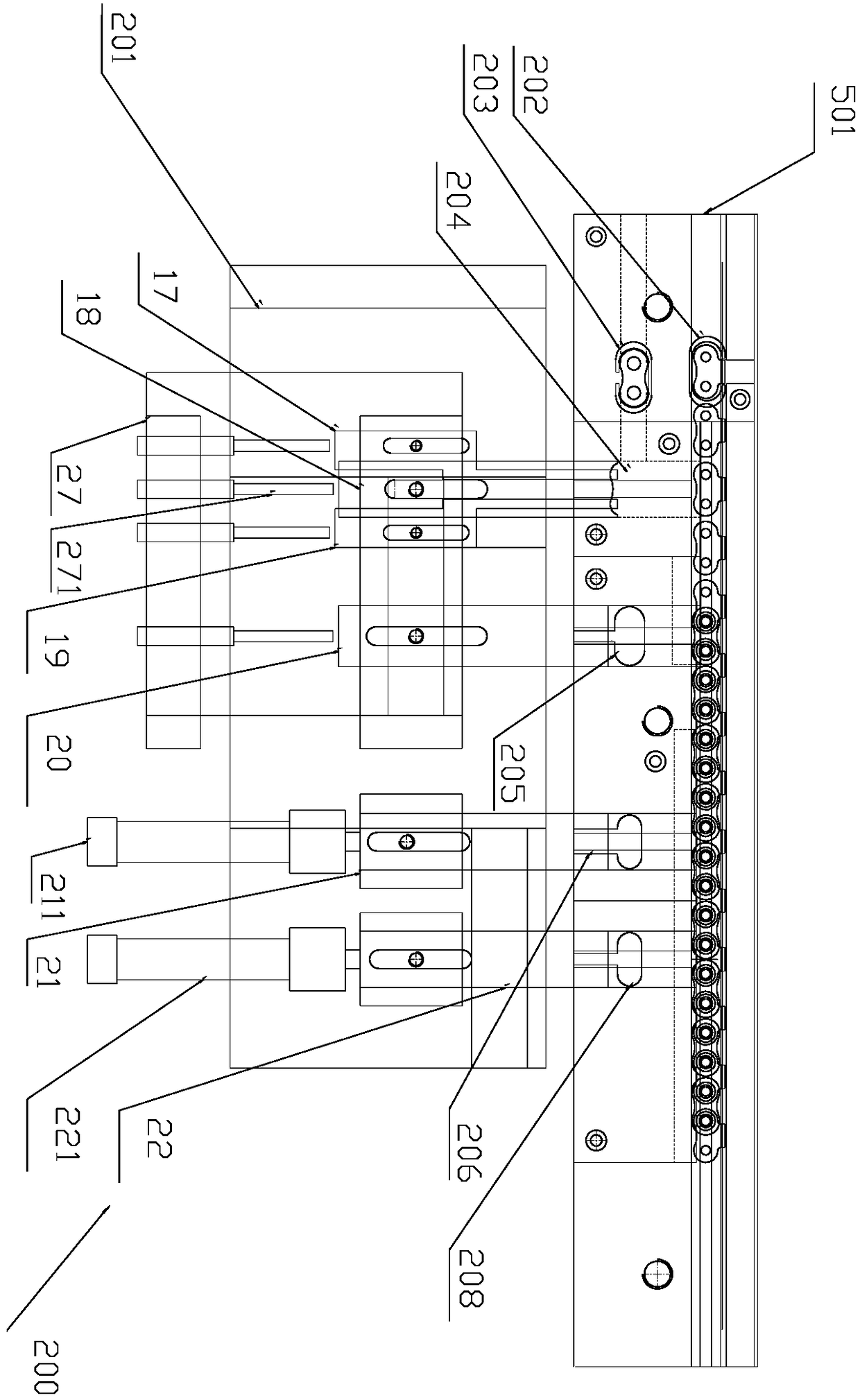

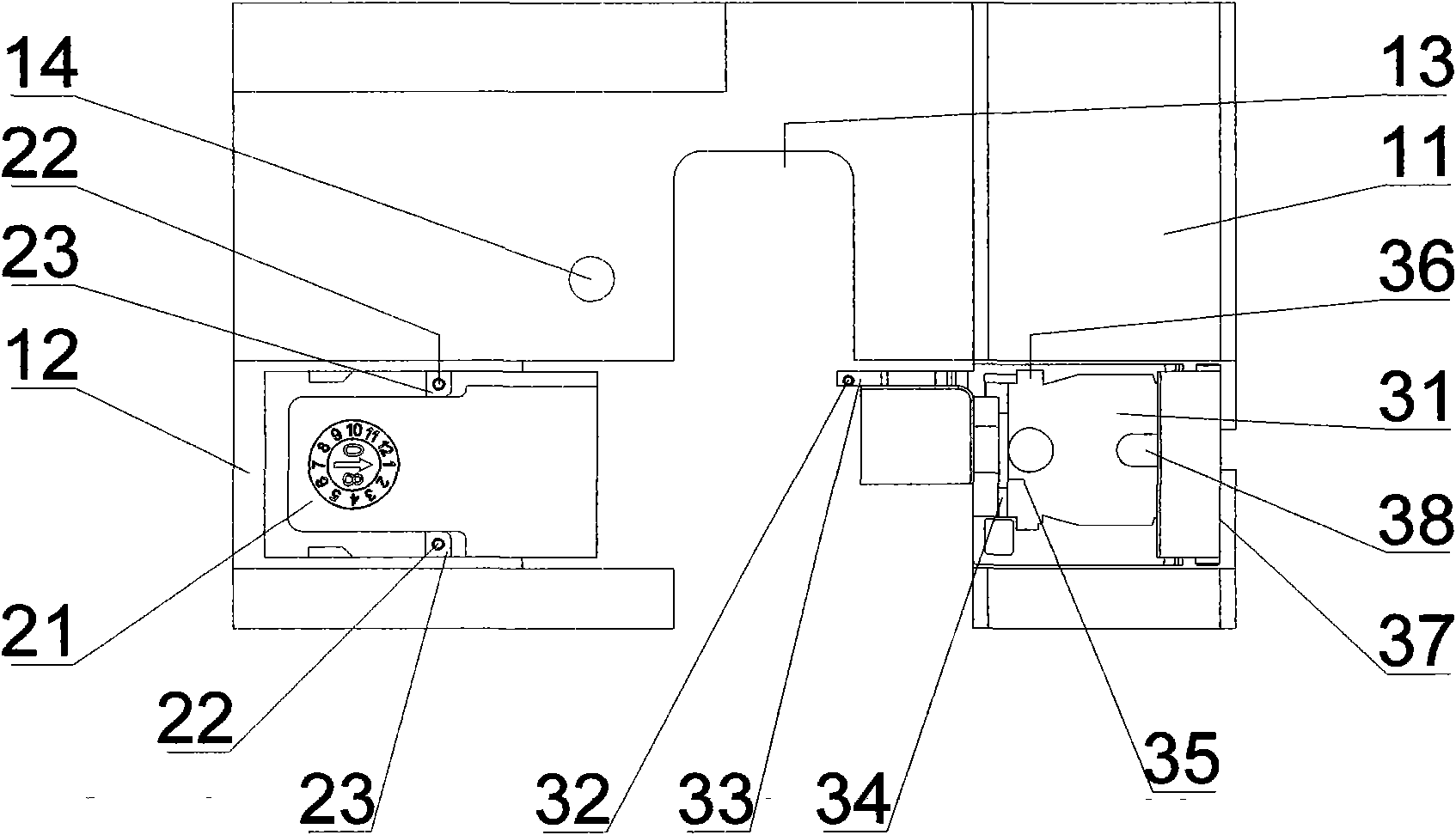

Chain accessory hybrid pushing assembly equipment

PendingCN109079086AAssembly positioning is accurateThe positioning mechanism is simple and stableMetal chainsEngineeringChain link

The invention relates to the technical field of chain assembly equipment, and particularly relates to chain accessory hybrid pushing assembly equipment. The chain accessory hybrid pushing assembly equipment comprises a working table, wherein an assembly groove is formed in the working table; a side push plate is arranged on one side of the assembly groove; the side push plate comprises a first pinroll push plate, a third lower chain plate push plate, a second pin roll push plate and a chain link push plate which are arranged on a push plate sliding block in sequence; the side push plate is further provided with a third transverse sliding block and a fourth transverse sliding block which are parallel to the push plate sliding block and driven by a third driving cylinder and a fourth driving cylinder which are correspondingly arranged. Synchronously pushed push plates are positioned on the same push plate sliding block through the arrangement of the side push plate, synchronous pushingof the side push plate can be completed through a second driving cylinder, the pushing efficiency is high, the application of a driver is greatly reduced, the equipment cost is reduced, the third driving cylinder and the fourth driving cylinder are arranged independently to push different types of upper chain plates, and the upper chain plates on the chain are of different structures and a proportion of irregularly-shaped chain plates.

Owner:浙江象牌链传动有限公司

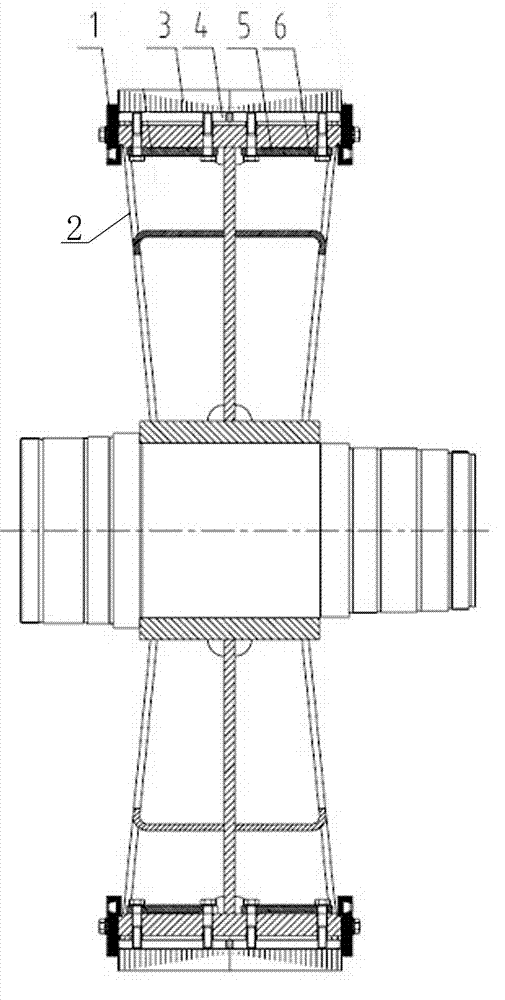

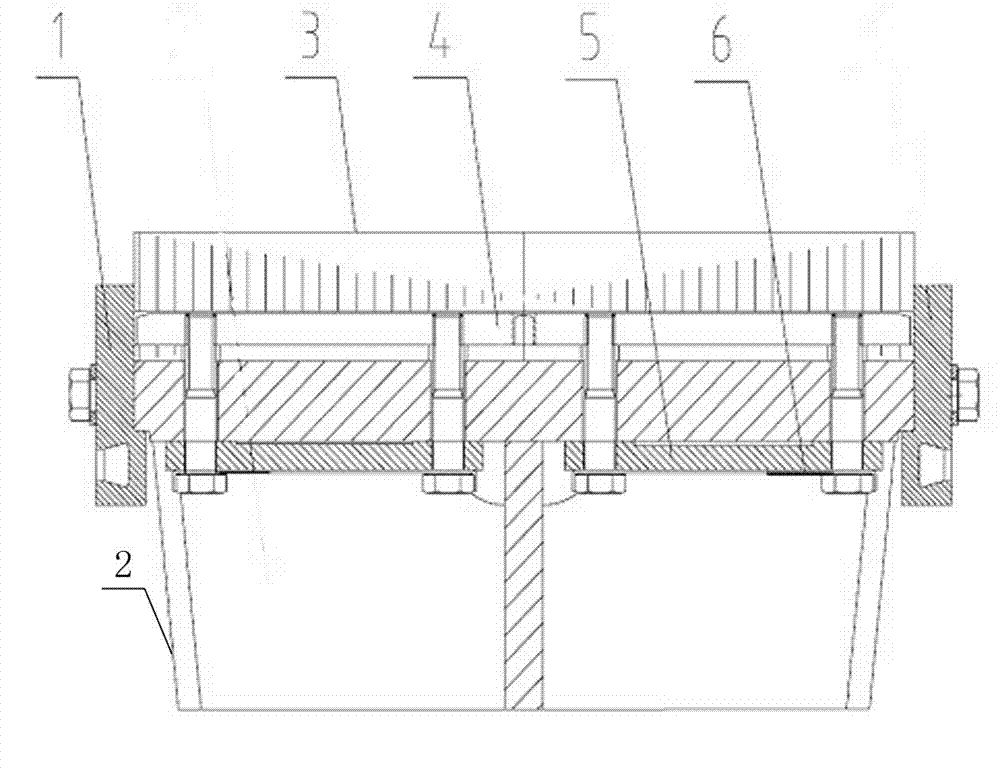

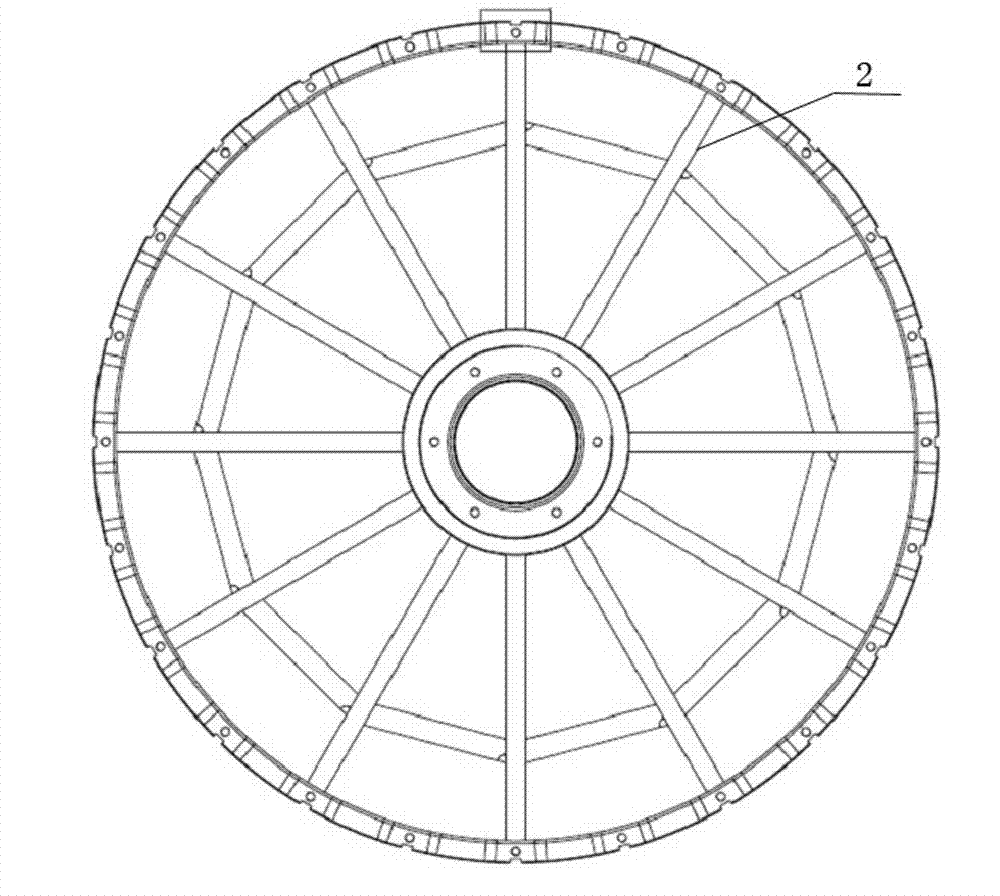

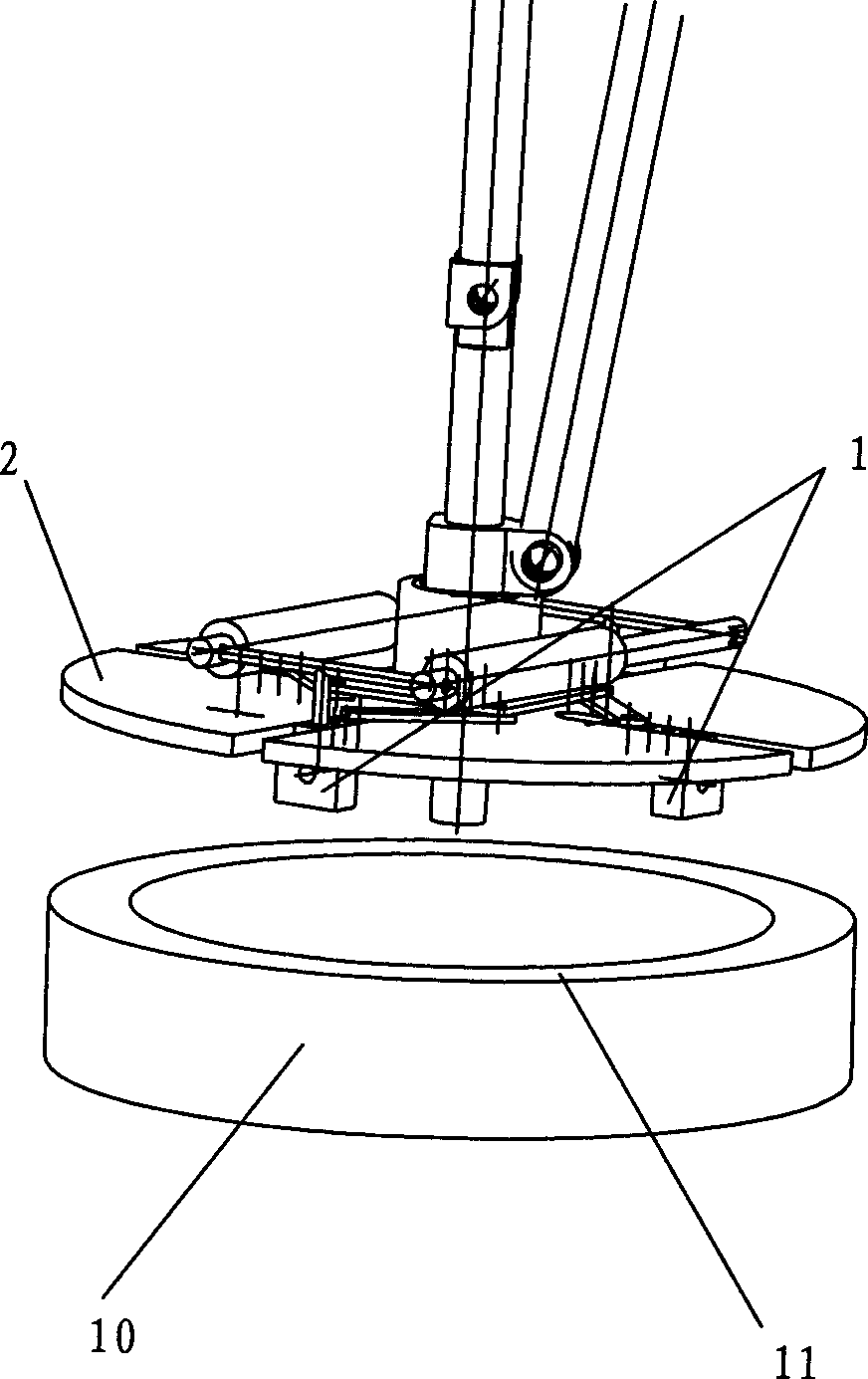

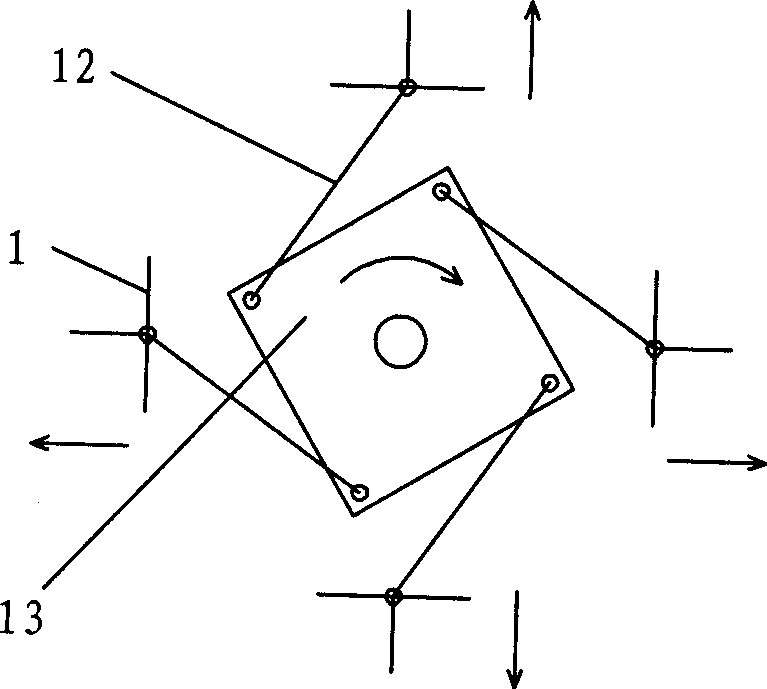

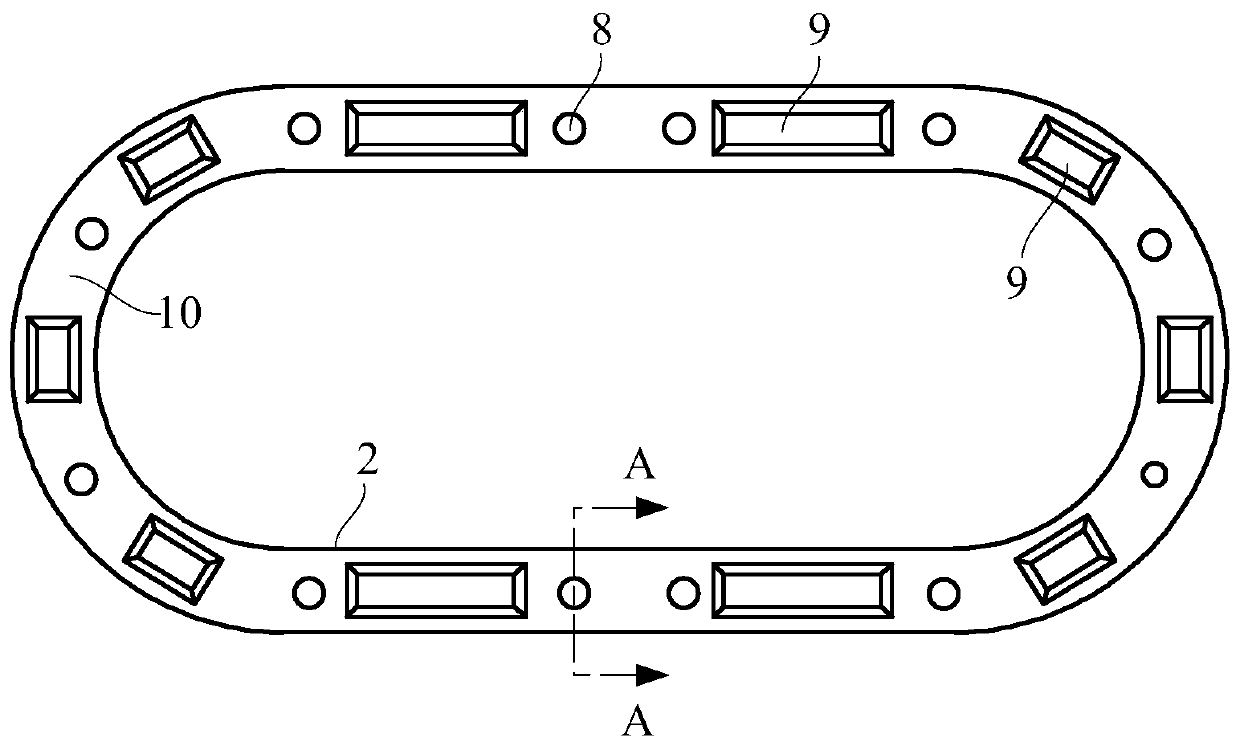

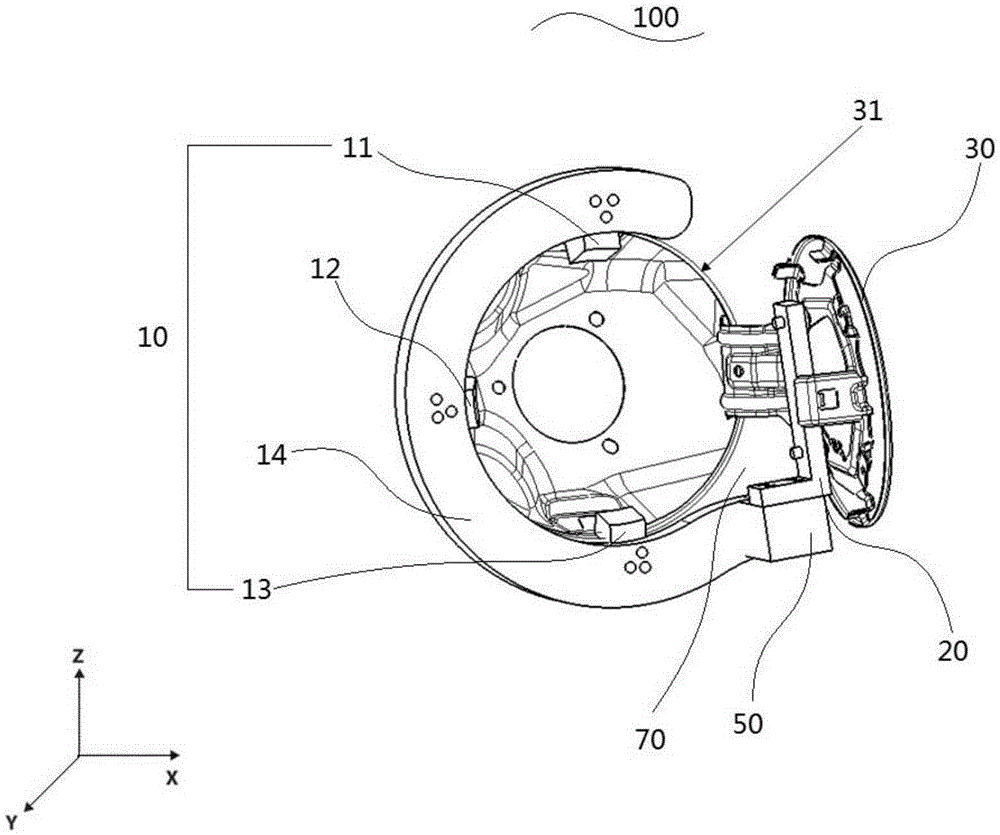

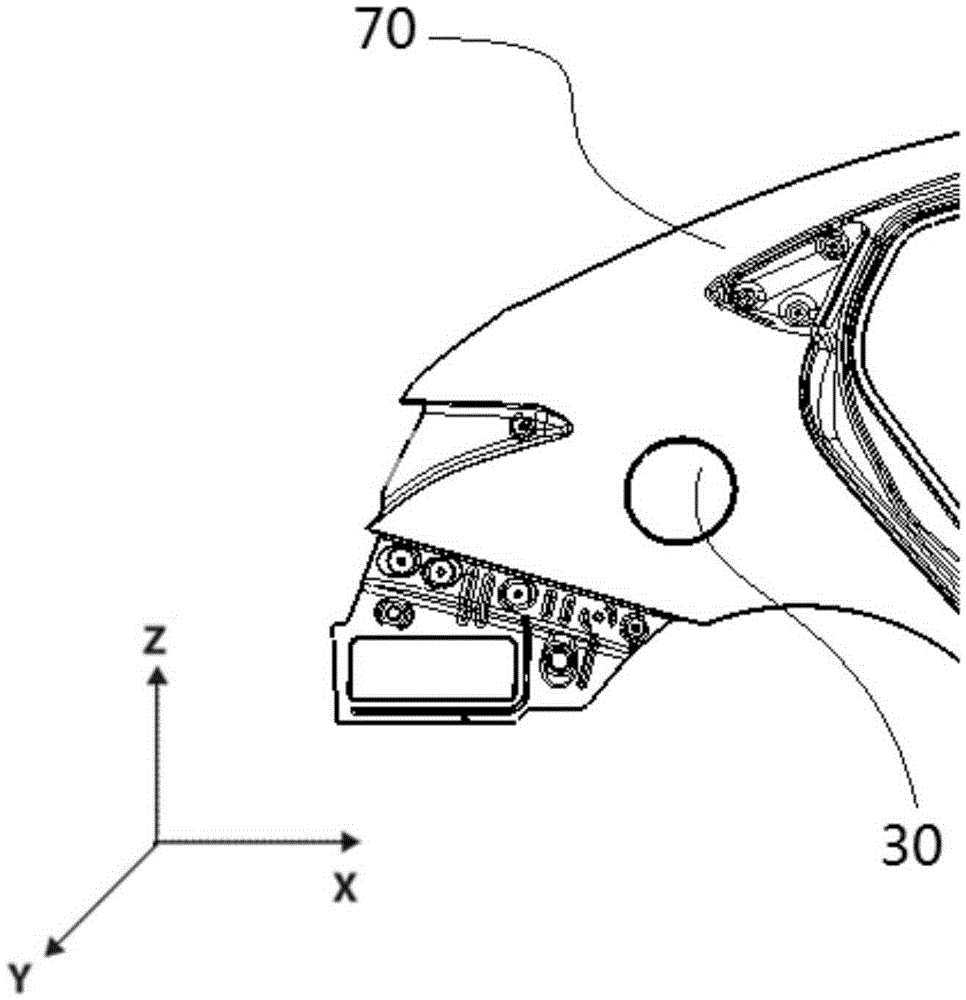

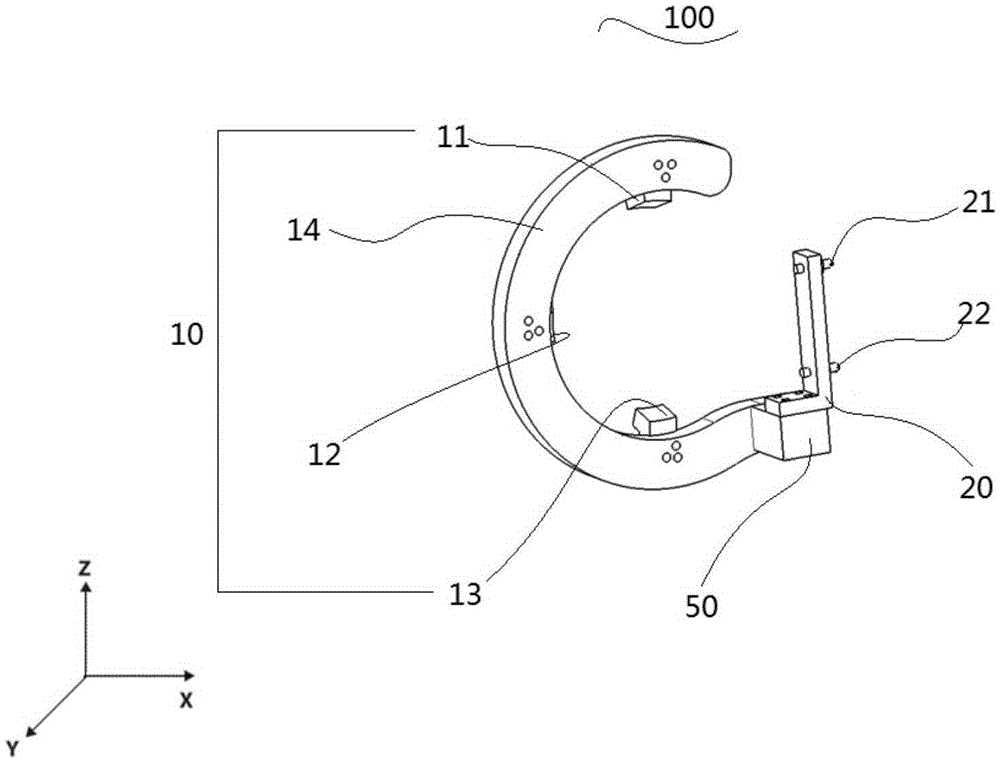

Compact permanent magnet wind generator rotor

ActiveCN102931741AAssembly positioning is accurateImprove ventilation efficiencyMagnetic circuit rotating partsMagnetic polesEngineering

The invention relates to a rotating device inside a permanent magnet wind generator, in particular to a compact permanent magnet wind generator rotor, solving the problem of an unreasonable structure of the permanent magnet wind generator rotor. The compact permanent magnet wind generator rotor comprises a rotor bracket, and a magnetic pole box provided with a permanent magnet mounting hole; magnetic steel is arranged inside the permanent magnet mounting hole; a fixed rod mounting hole is arranged on the magnetic pole box; a bolt perforating hole is arranged on the contact surface of the magnetic pole box and the rotor bracket; the bolt perforating hole is communicated with the fixed rod mounting hole; a locating lug boss is also arranged on the surface contacting a magnet yoke on the rotor bracket on the magnetic pole box; a radial bolt hole and a guide locating groove matched with the locating lug boss are arranged on the magnet yoke on the rotor bracket, and a fixed rod with the bolt hole is arranged inside the fixed rod mounting hole. The compact permanent magnet wind generator rotor is novel in structure; the performance of a motor is improved; the manufacturing cost of the motor rotor is reduced, and the stability of the entire structure of the rotor is improved.

Owner:CRRC YONGJI ELECTRIC CO LTD

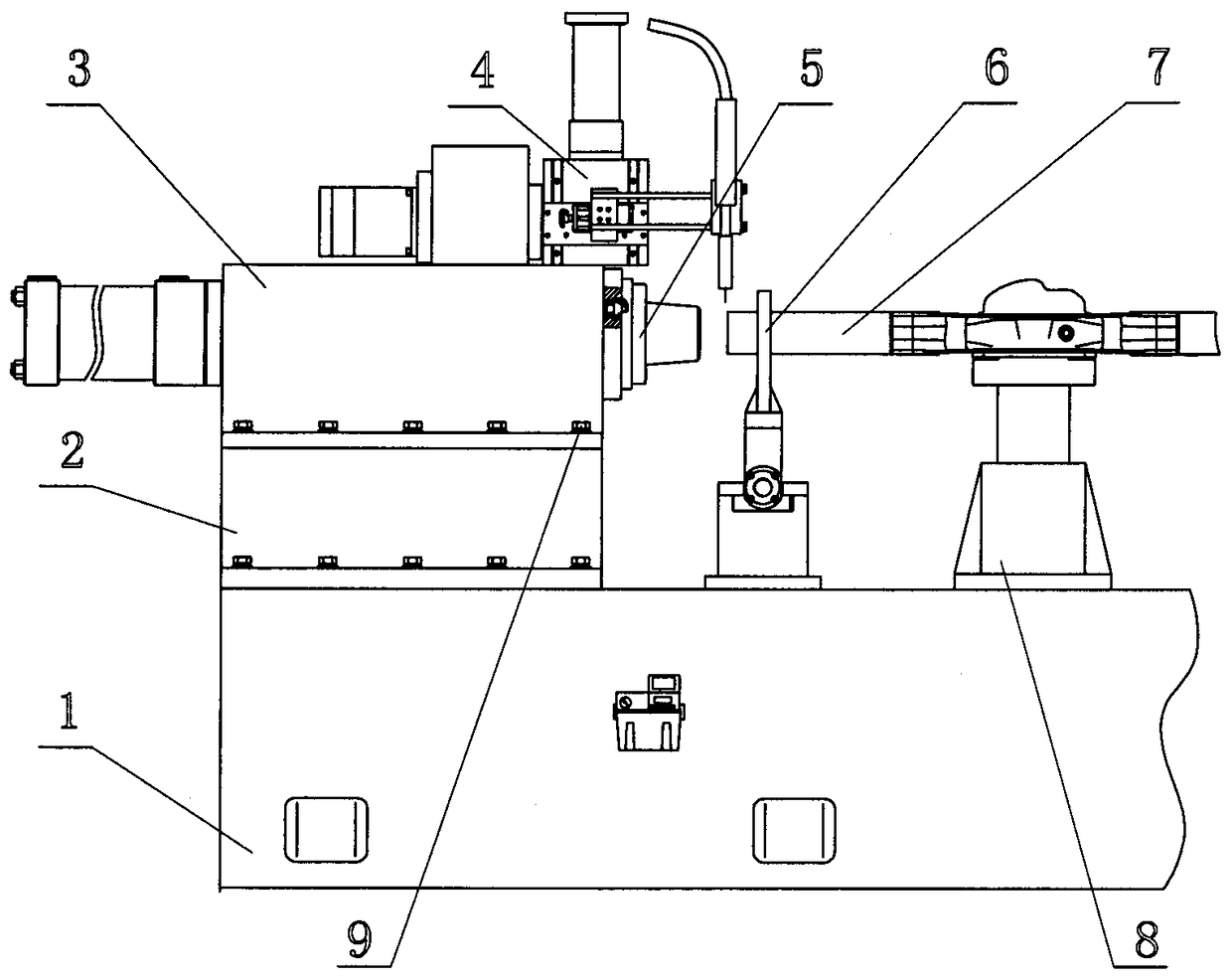

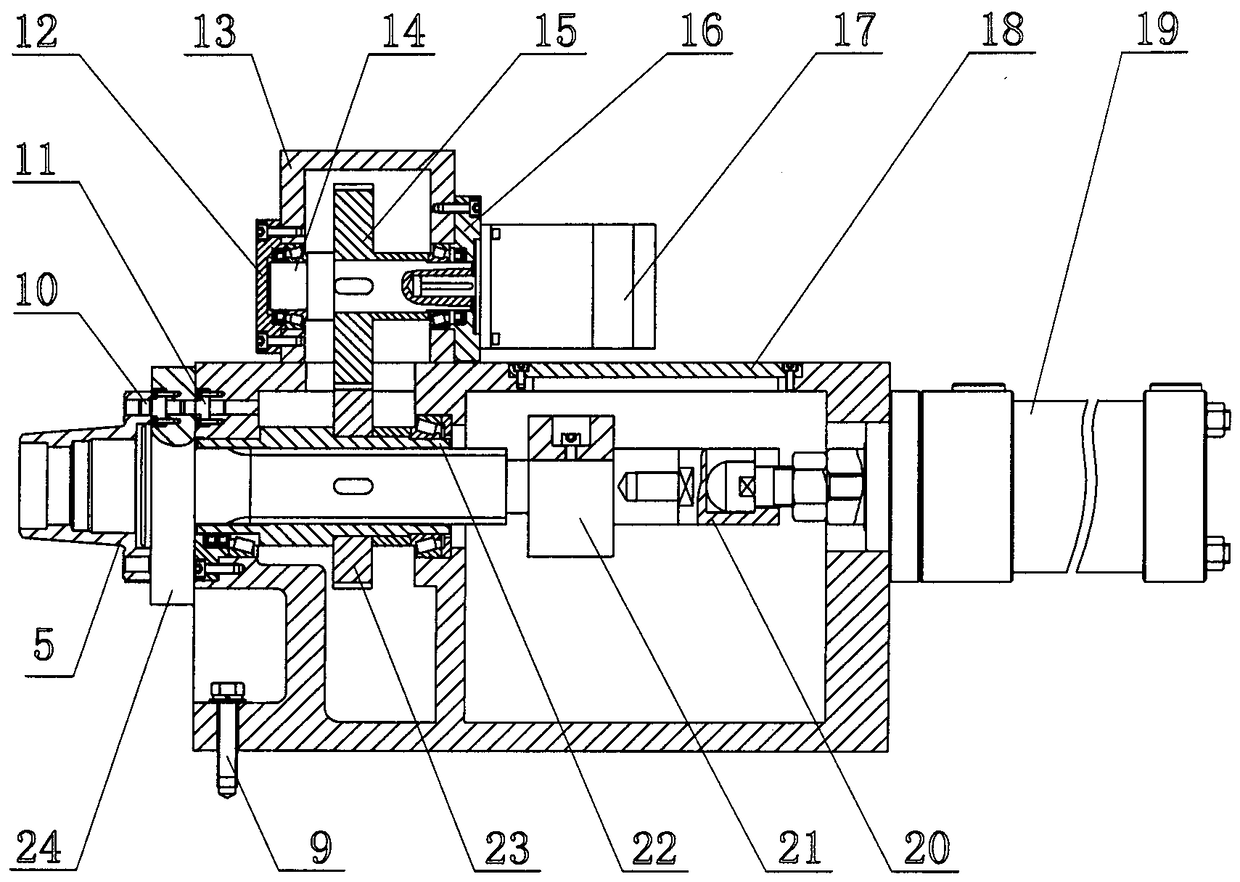

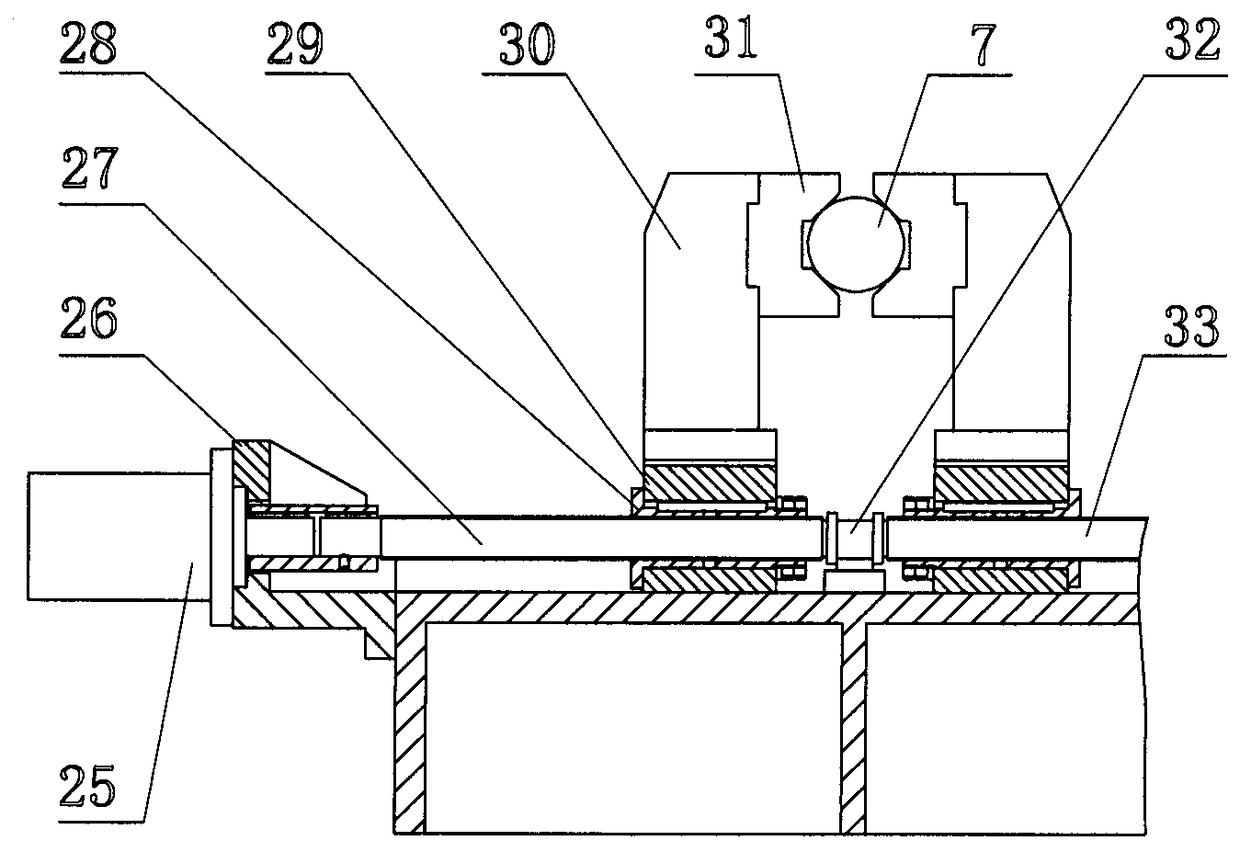

Automobile rear axle housing flange plate press-fitting welding device

PendingCN108213923AEnsure mounting surface accuracyGuaranteed accuracyWelding/cutting auxillary devicesArc welding apparatusEngineeringWelding deformation

The invention discloses an automobile rear axle housing flange plate press-fitting welding device which is used for solving the problems of being multiple in procedure, low in mounting efficiency, incapable of guaranteeing welding precision of flange plates and the like in an existing automobile rear axle housing flange plate press-fitting process. The automobile rear axle housing flange plate press-fitting welding device comprises a combined lathe bed, welding mechanisms and a clamping mechanism. According to the technical characteristics, the combined lathe bed is composed of a main body lathe bed and side lathe beds, wherein the middle of the upper surface of the main body lathe bed is provided with a lifting clamping mechanism used for limiting and smoothing a rear axle housing; rotating mechanisms with adjustable feeding strokes comprise hydraulic feeding units and rotary driving units, and the welding mechanisms are arranged on the upper surfaces of the side lathe beds; and the clamping mechanism comprises a self-centering clamping mechanism and the lifting clamping mechanism, and the lifting clamping mechanism is adjusted to enable the axes of flange plates and the axis of an axle housing pipe to be located on the same central line. According to the automobile rear axle housing flange plate press-fitting welding device, the structural design is reasonable, the technological process is simplified, assembling and positioning are accurate, welding deformation is easy to control, while precision of the mounting surfaces of the flange plates is ensured, the machining costis reasonably reduced, the quality and production efficiency of a finished product are improved, and therefore driving safety is guaranteed.

Owner:LIAONING SG AUTOMOTIVE GRP CO LTD

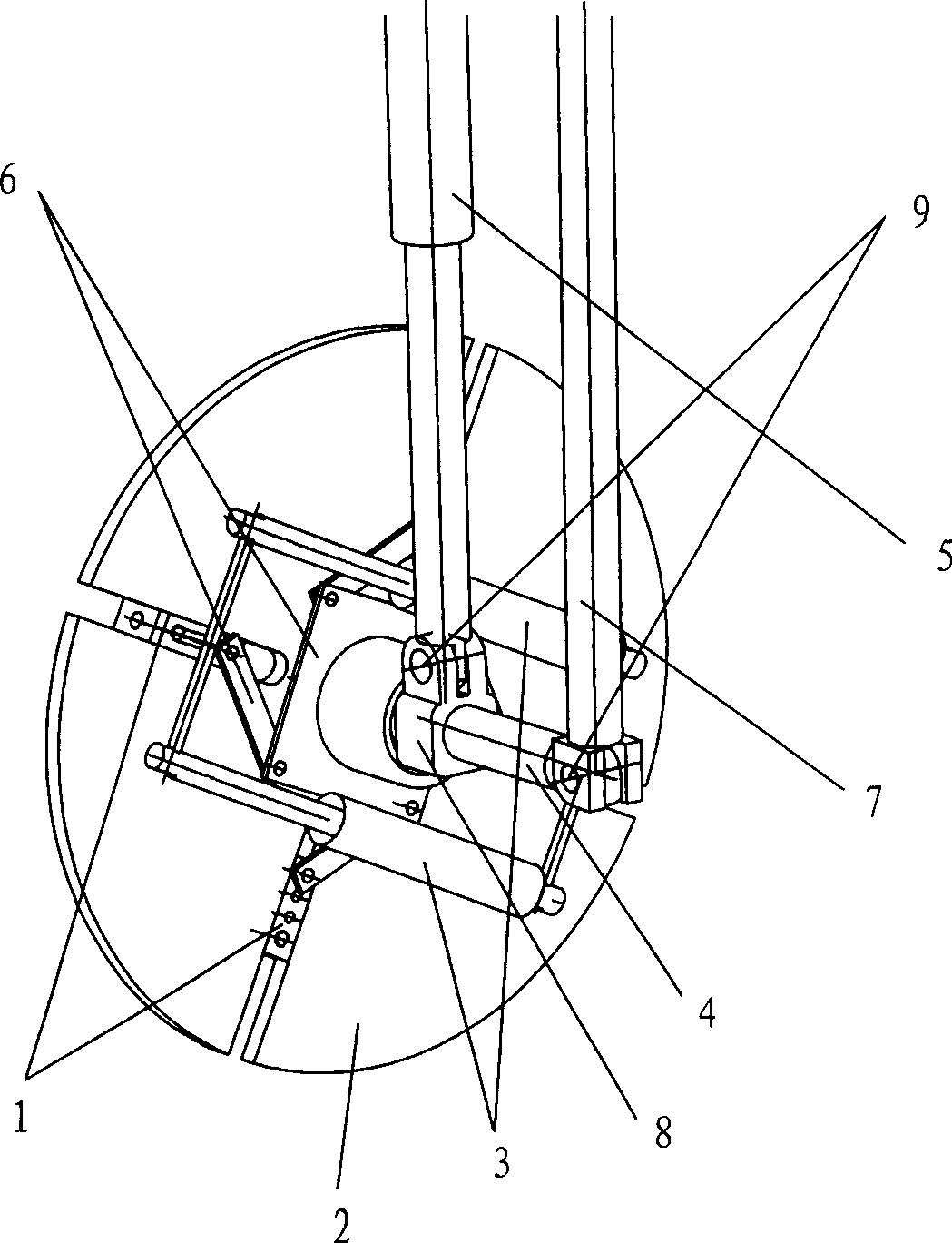

Flywheel casing on-line rapid assembling device and method

InactiveCN101424366AEasy to grabAssembly precisionMachine framesMetal-working hand toolsEngineeringFlywheel

The invention discloses a flywheel casing online quick assembly device. The device comprises a clamping mechanism, a rotating mechanism and a turnover mechanism, wherein the clamping mechanism is matched with a flywheel casing and is arranged on the rotating mechanism, and the turnover mechanism is hinged with the rotating mechanism. The invention also discloses a method for online quick assembly of the flywheel casing. The method assembles the flywheel casing by using the flywheel casing online quick assembly device. The device reduces the labor intensity of workers, and improves assembly quality and working and production efficiency.

Owner:GUANGXI YUCHAI MASCH CO LTD

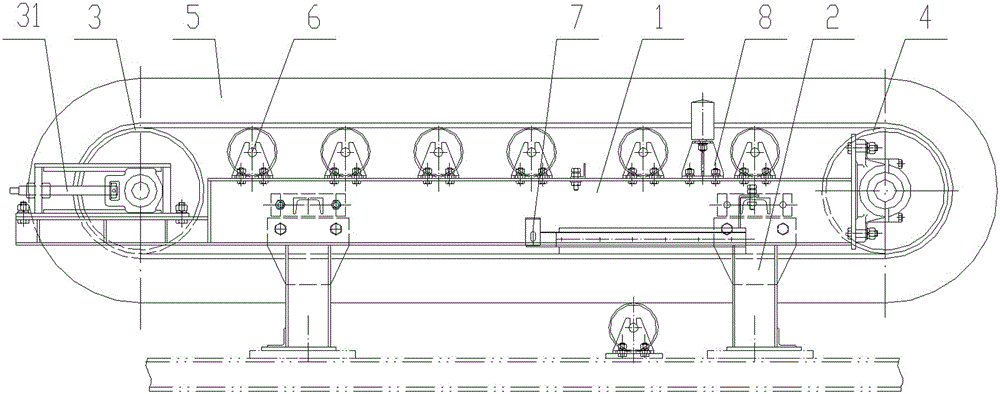

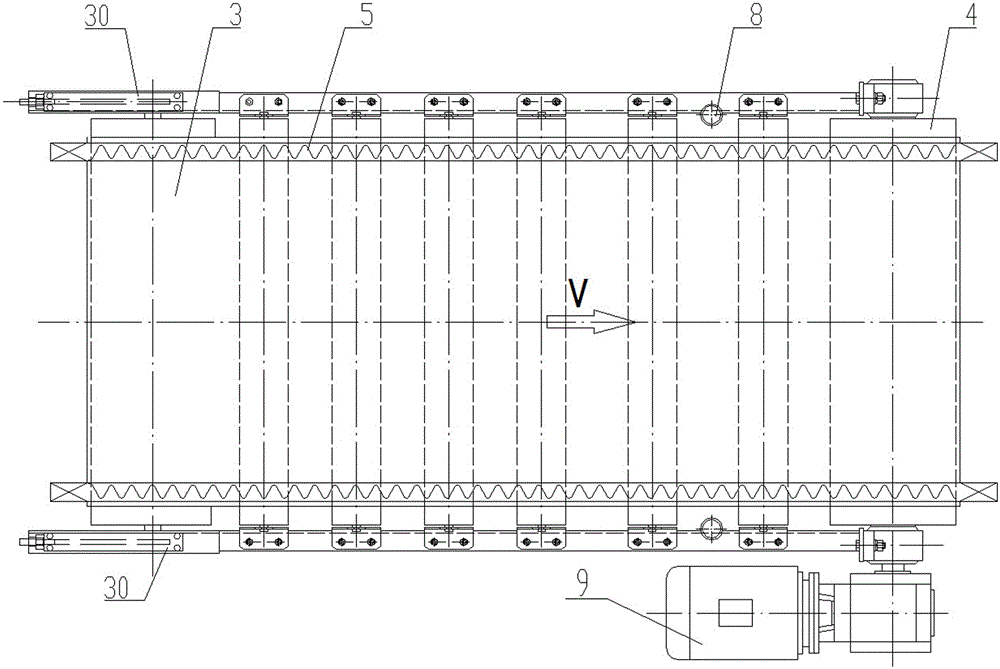

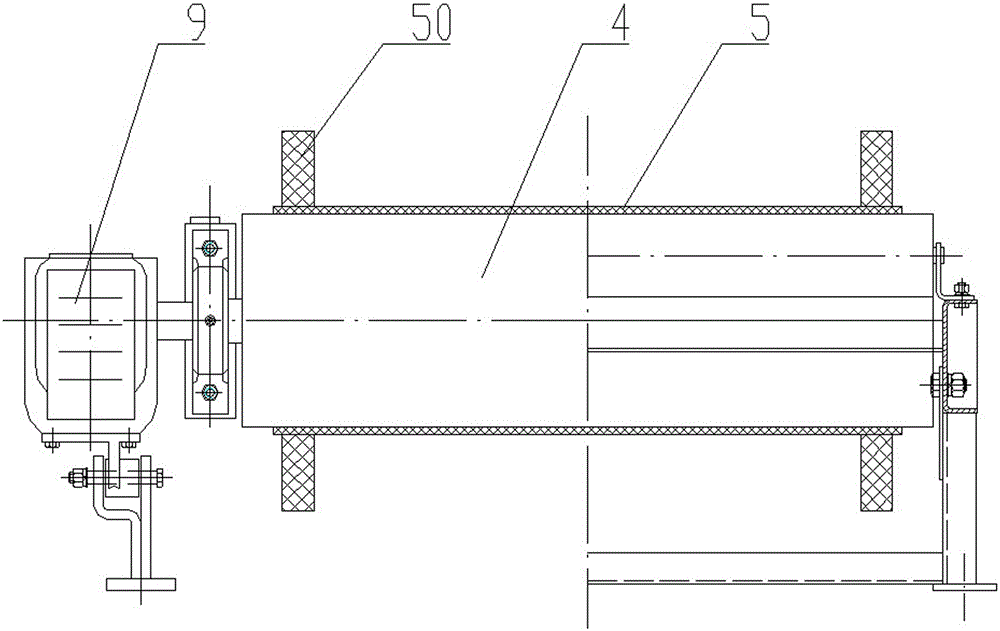

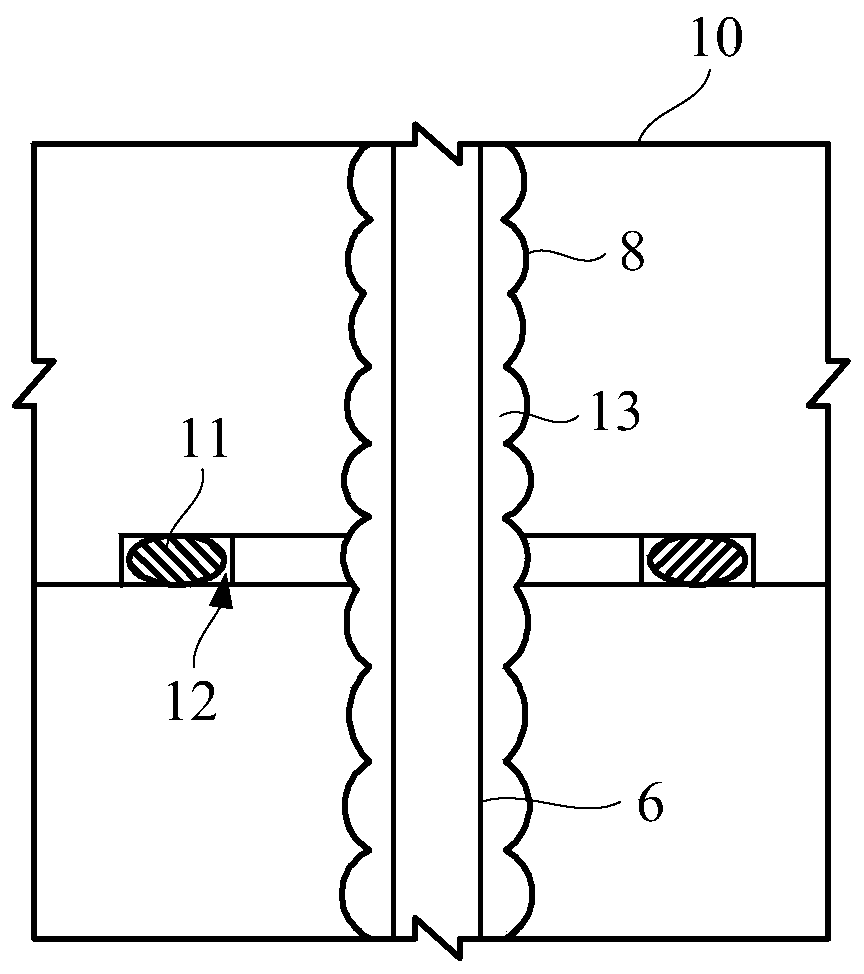

Quick disassembly and assembly annular walled rubber belt feeder

InactiveCN105129328AFlexible installationHeight adjustable outriggersConveyorsEngineeringMechanical engineering

The invention provides a quick disassembly and assembly annular walled rubber belt feeder. A rubber belt can be effectively prevented from deviating and scattering materials; equipment is stable and reliable to run, convenient to disassemble and maintain, and high in transmission efficiency; and the production cost is reduced. The quick disassembly and assembly annular walled rubber belt feeder comprises a rack, a tension drum, a transmission drum, an upper supporting roller group, a lower supporting roller group, a tension device and a power device, wherein a plurality of landing legs are arranged under the rack; a drum-type structure is adopted by at least one of the tension drum and the transmission drum; an annular conveyer belt is arranged between the tension drum and the transmission drum in a tensioning manner; the upper supporting roller group and the lower supporting roller group are used for carrying the annular conveyer belt and materials; the tension device is connected with the tension drum; the power device comprises a geared motor; the geared motor is arranged on the rack, and is in transmission connection with the transmission drum; corrugated sidewalls are vulcanized twice on the left side and the right side of the annular conveyer belt along the length direction; and the annular conveyer belt is free of a diaphragm plate and free of a marginal side.

Owner:安徽攀登重工股份有限公司

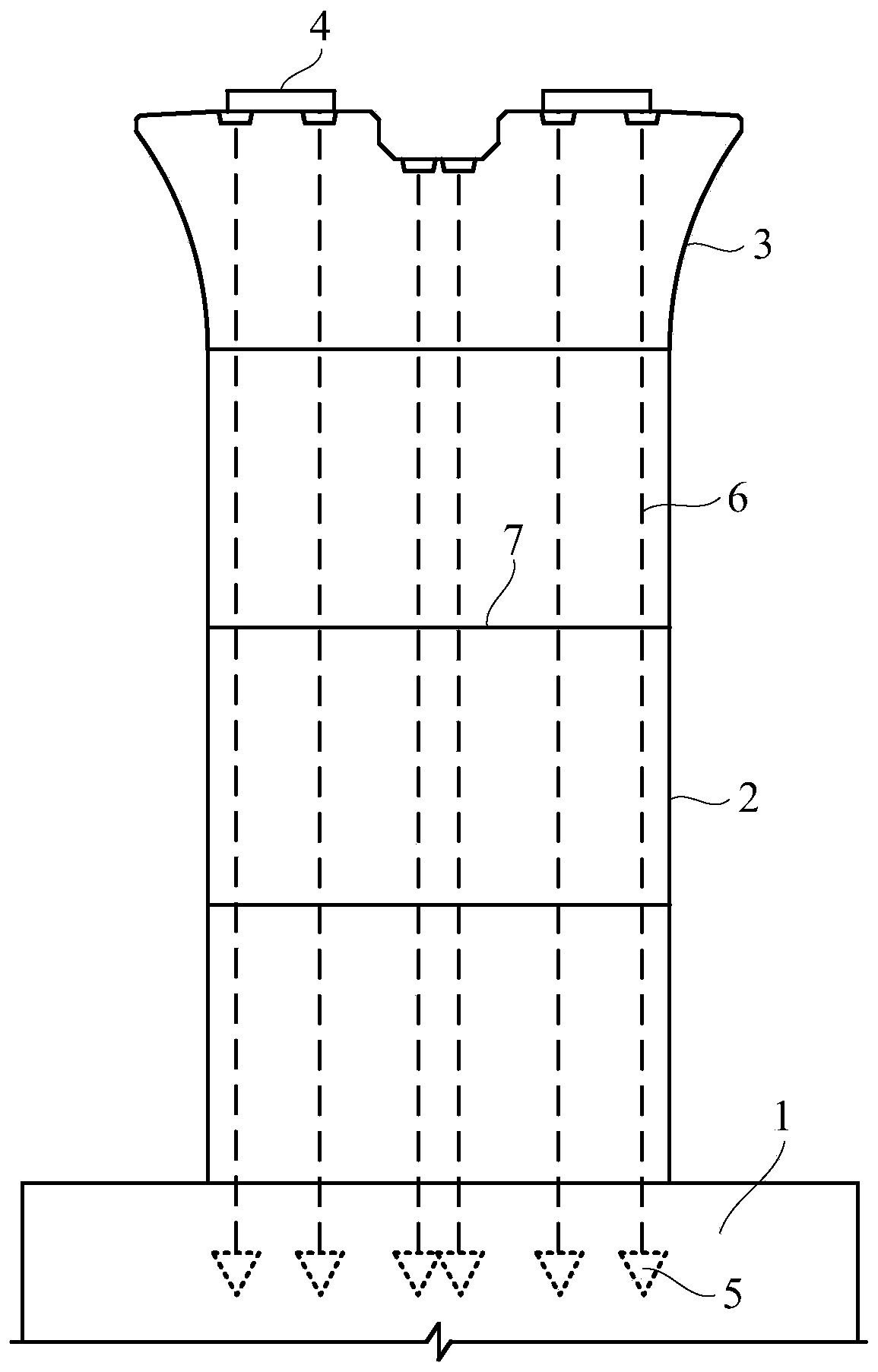

Railway assembled hollow pier and construction method thereof

InactiveCN111335155ASimple designReasonable designBridge structural detailsBridge erection/assemblyButt jointPre stress

The embodiment of the invention relates to the technical field of railway pier construction, and especially relates to a railway assembled hollow pier and a construction method thereof. The railway assembled hollow pier comprises a bearing platform, standard pier stud sections, pier top pier stud sections and padstones; the bearing platform and the padstones are both manufactured by in-situ casting; the pier top pier stud sections and the standard pier stud sections are all prefabricated parts; the standard pier stud sections are of hollow tubular structures; a self-locking anchorage device fixing end, a steel strand corrugated pipe and an embedded steel bar are embedded in the bearing platform; the bearing platform, the standard pier stud sections and the pier top pier stud sections are assembled and positioned through a plurality of concave-convex shear keys; and the top ends of the prestress steel strands are tensioned on the tops of the pier top pier stud sections, and the guide heads at the bottom ends of the prestress steel strands are fixedly connected with the self-locking anchorage device fixing ends in a self-locking mode. The railway assembled hollow pier can meet the rigidity design requirement of a railway bridge, the light design concept is achieved, all components are in precise butt joint, the assembling reliability is achieved, and the construction period is shortened.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

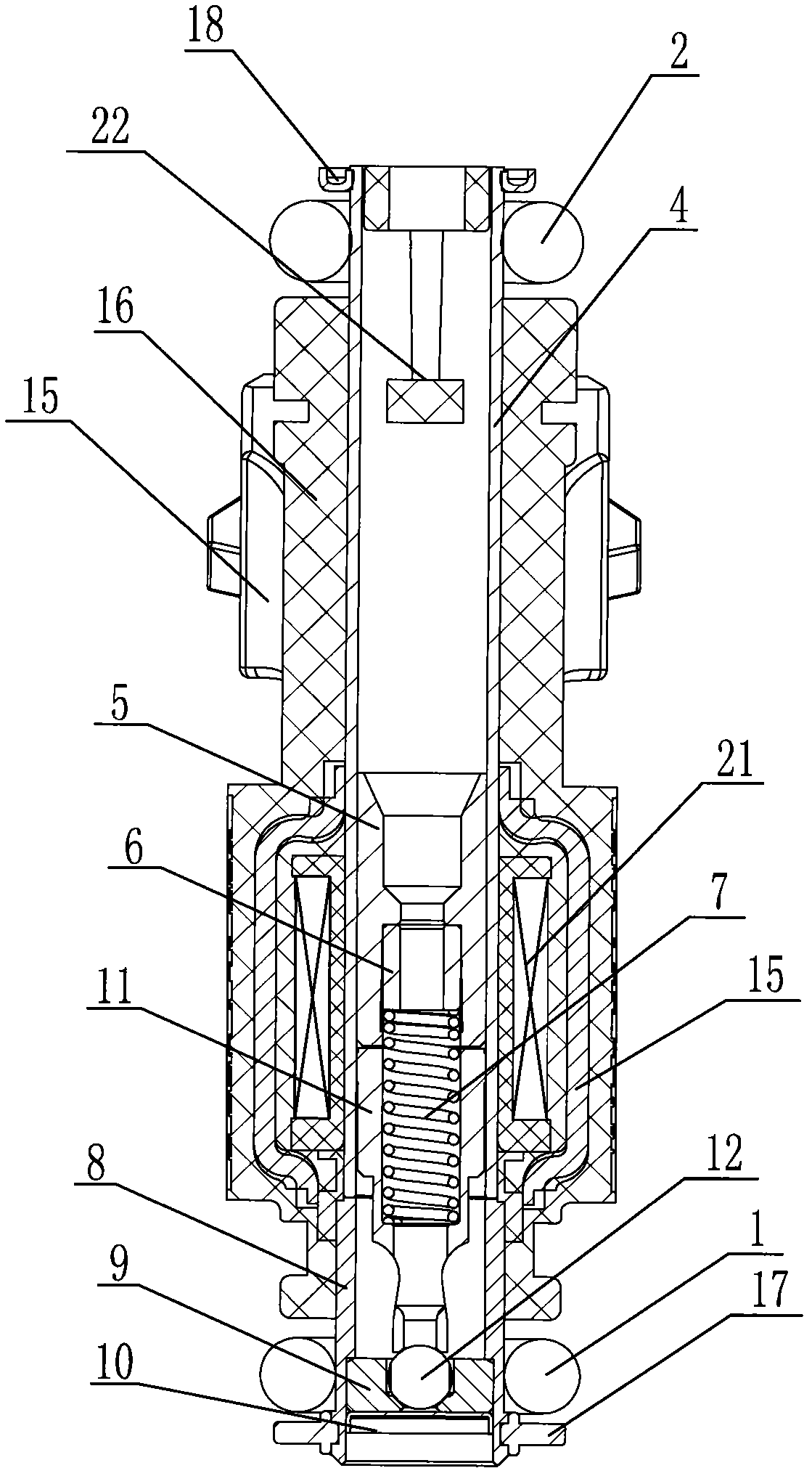

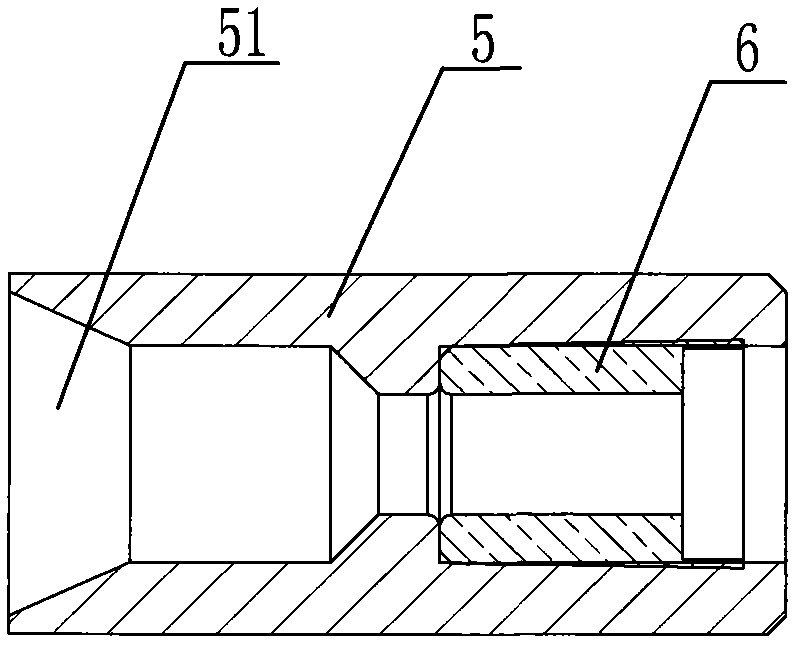

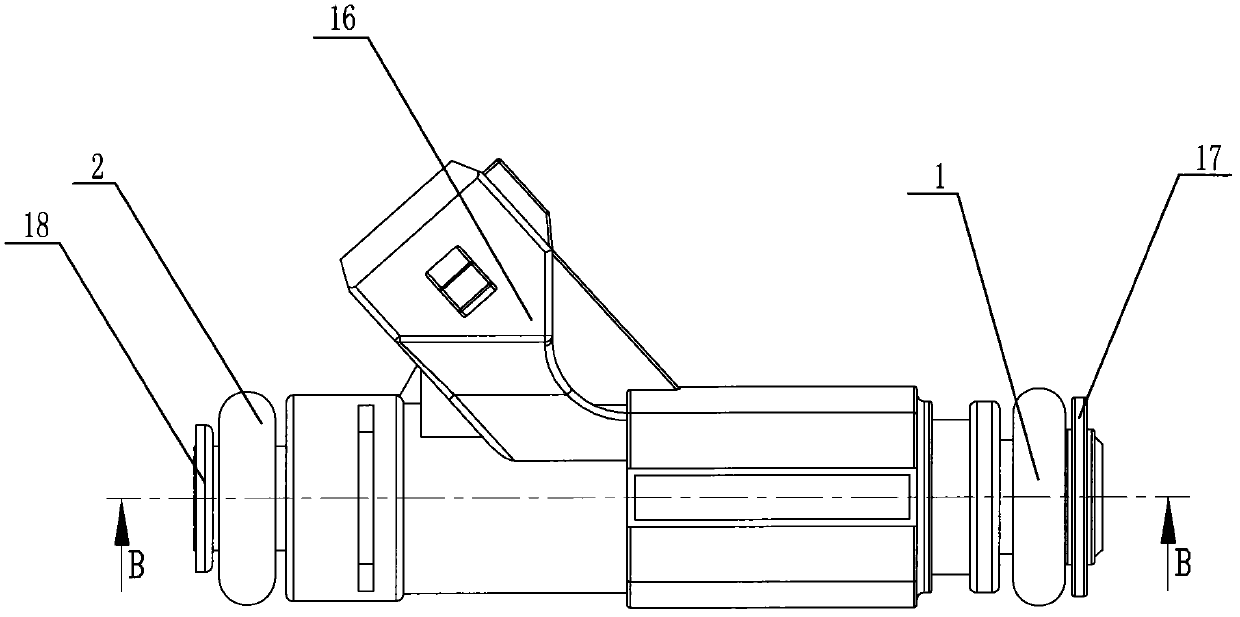

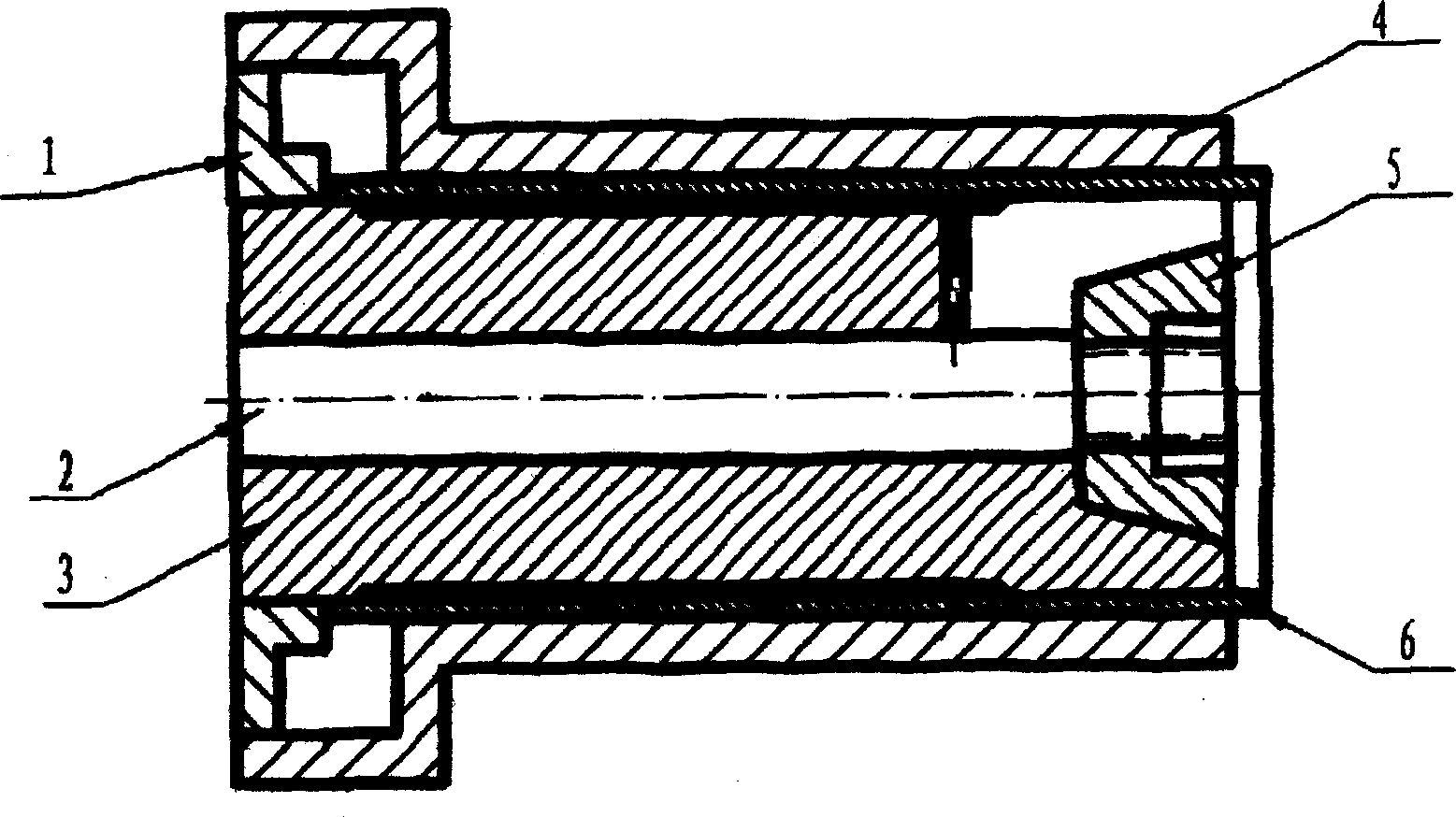

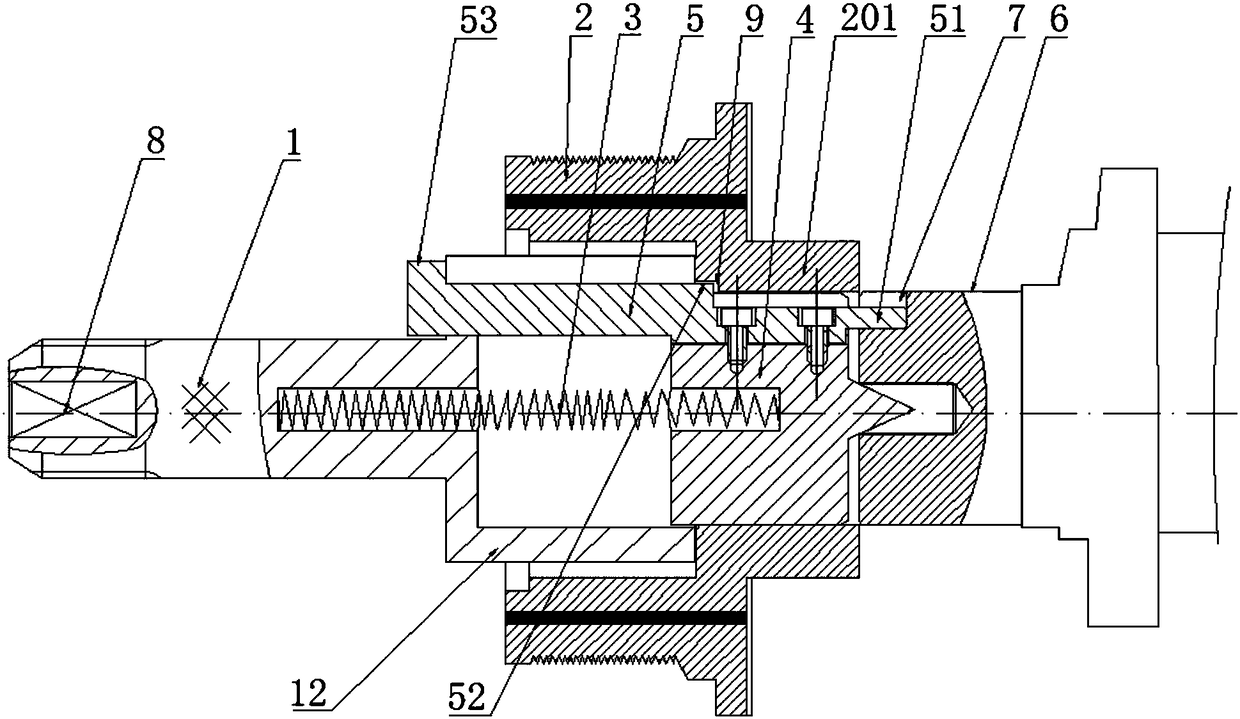

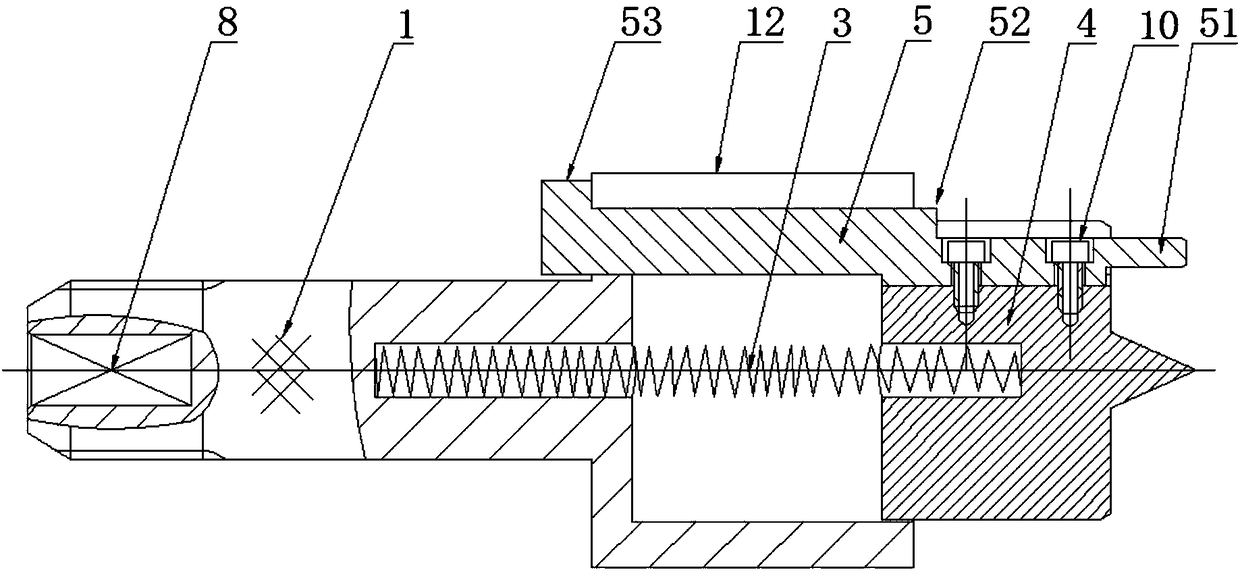

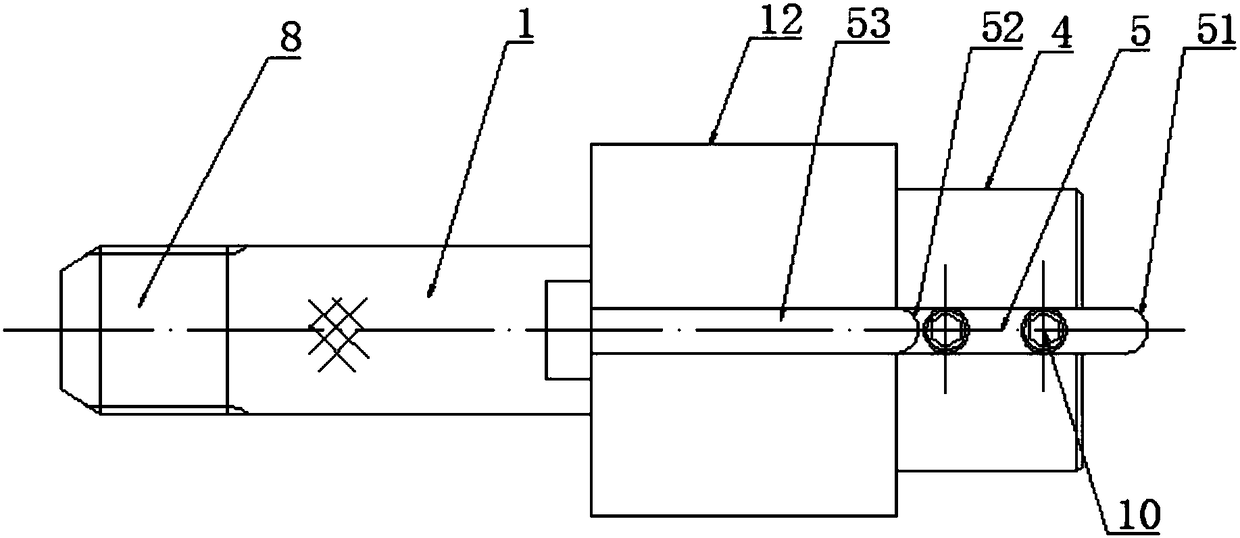

Electromagnetic fuel injection valve

InactiveCN101949344ASimple designSimple processFuel injection apparatusMachines/enginesSteel ballEngineering

The invention discloses an electromagnetic fuel injection valve, which comprises a spray pipe inlet. An iron core is arranged in the spray pipe inlet, and a coil is wound on the iron core; the coil is connected with an electrode plate; a spring is arranged in the iron core; one end of the spring is pressed in the iron core, while the other end is pressed on a magnet; a spray pipe main body is sleeved outside the magnet; the spray pipe main body is in sealed connection with the spray pipe inlet; a valve seat is arranged in the spray pipe main body and is provided with a valve hole; and the front end of the magnet is fixed with a steel ball which is matched with the valve hole and is used for closing and opening the valve hole. The injection valve has the advantages of accurate control of oil injection, quick dynamic response, high product stability, simple structure and low processing cost.

Owner:浙江冯仕特电喷技术有限公司

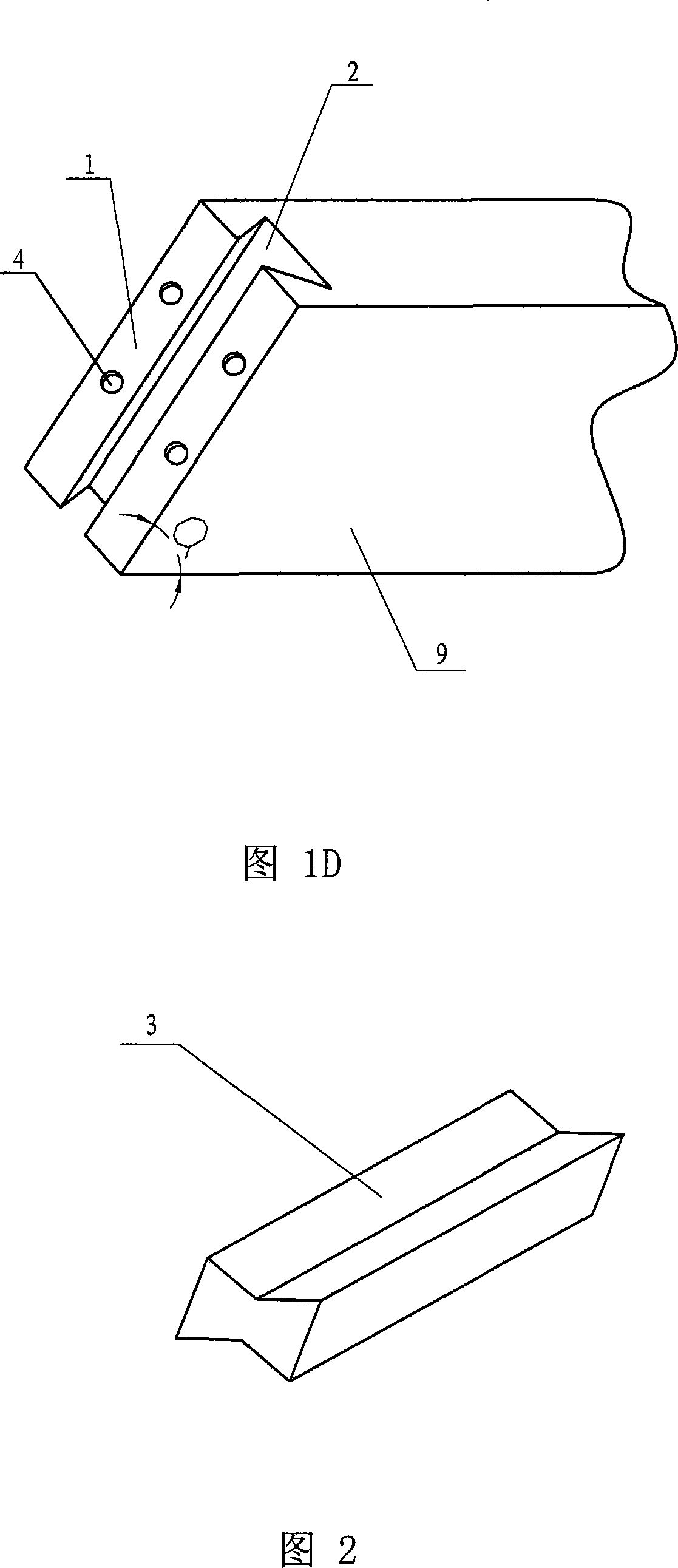

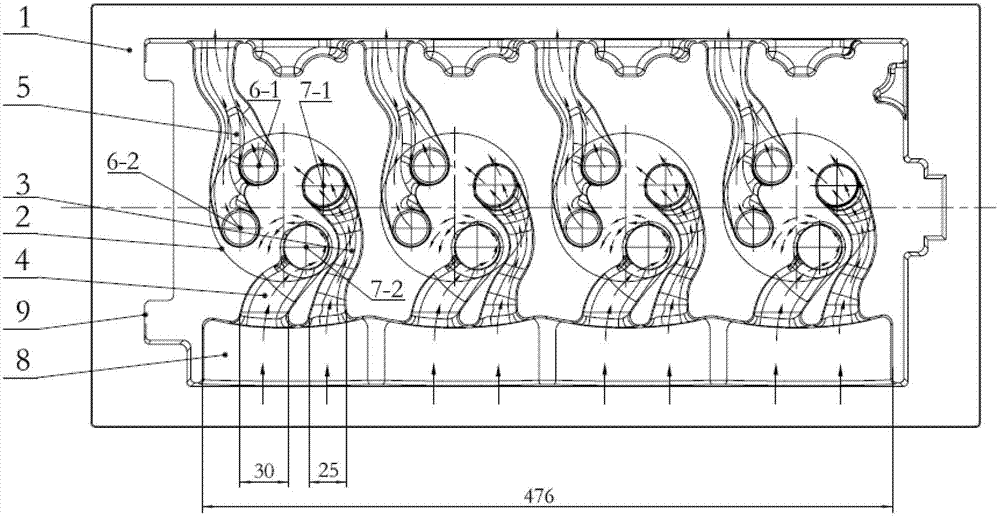

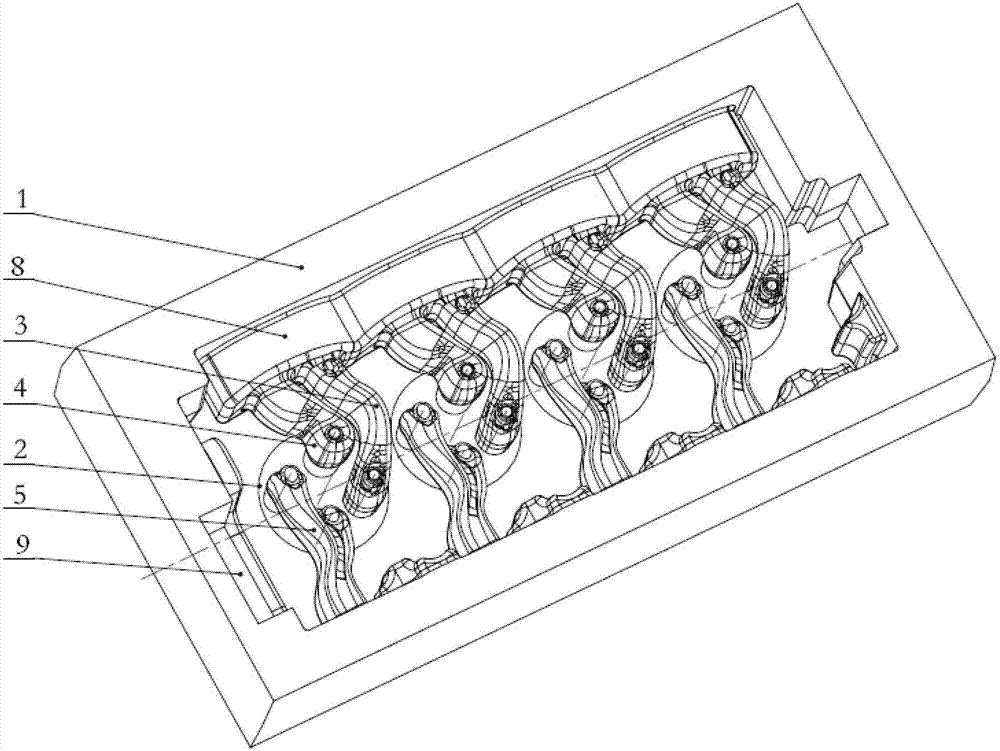

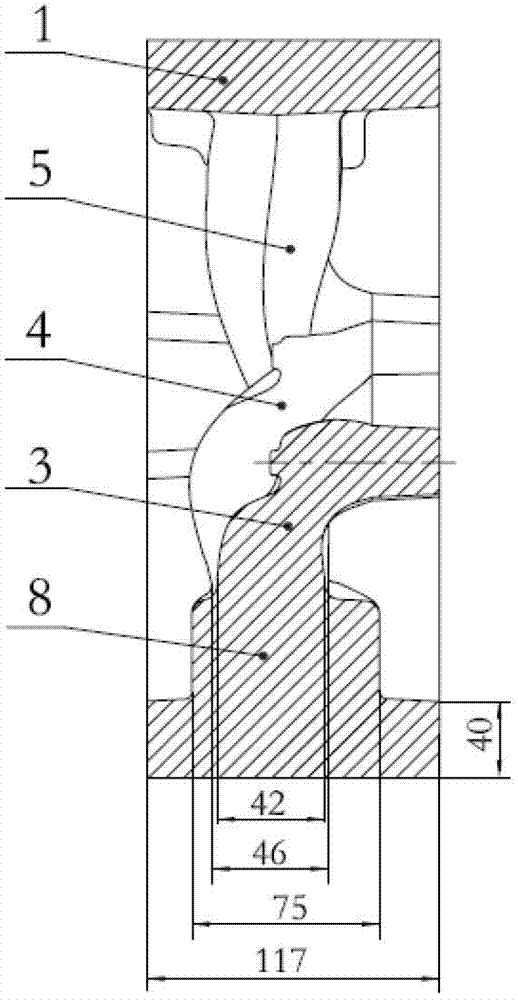

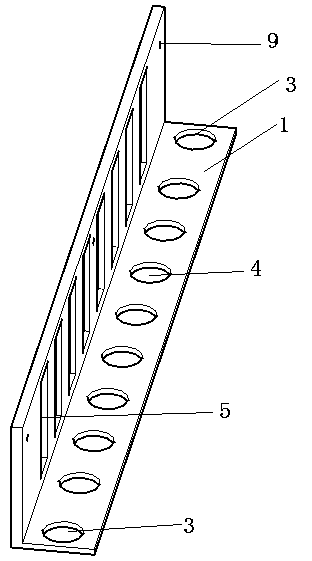

Frame structure integral air flue for multi-valve diesel engine

InactiveCN102733984AAssembly positioning is accurateReduce assembly errorsCylinder headsFoundry mouldsFlueEngineering

The invention discloses a frame structure integral air flue for a multi-valve diesel engine. An air flue outer frame is provided with 4-6 cylinders; each cylinder is provided with a tangential air inlet channel and a spiral air inlet channel and a parallel air exhaust channel; the air inlet channels and the parallel air exhaust channels are uniformly distributed on the peripheries of the corresponding cylinders ; two branches of each parallel air exhaust channel are communicated with a first air exhaust valve and a second air exhaust valve respectively; the tangential and spiral air inlet channels are communicated with a first air inlet valve and a second inlet valve respectively; the air inlet cavity of each pair of tangential and spiral air inlet channels is provided with an inwardly-concave integral sand core; one end of the inwardly-concave integral sand core is connected with the outer frame, and the other end of the inwardly-concave integral sand core is connected with the tangential and spiral air inlet channels; the air flue outer frame is provided with a cooling water jacket positioning groove; and the central line of each cylinder is coincided with the central line of the positioning groove. Due to the adoption of the frame structure integral air flue, the swirl rate of each cylinder air flue can be kept uniform and consistent, each air flue core is assembled and positioned accurately, the assembling error is effectively lowered, the problem of non-uniform burning of each cylinder caused by inconsistent swirl rates is effectively improved, and the economic efficiency and discharging level of the diesel engine are improved.

Owner:东风朝阳朝柴动力有限公司

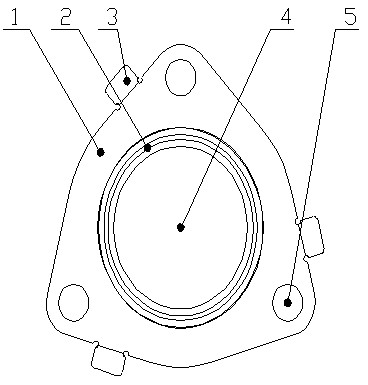

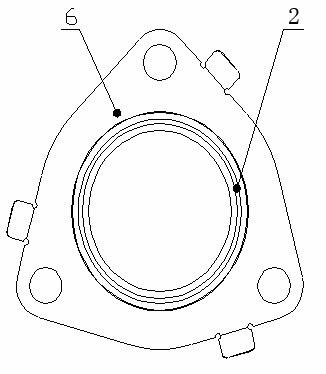

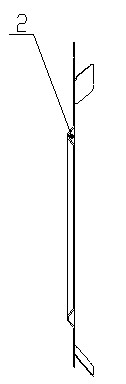

Flat-face flange sealing gasket for automotive exhaust system

InactiveCN102108914AGuaranteed coaxialityImprove assembly accuracyEngine sealsExhaust apparatusSoft materialsEngineering

The invention discloses a flat-face flange sealing gasket for an automotive exhaust system, which comprises an upper piece and a lower piece, which have the same shape and are overlapped and welded into a whole; through holes of the same size as the central hole of a flat-face flange of an exhaust pipe connector are formed in the middle of the upper piece and the lower piece; bosses are punched around the through holes on different sides of the upper piece and the lower piece respectively; the bosses form a sealing zone the flat-face flanges; furthermore, positioning pawl sheets are uniformly distributed on the outer circumference of the upper or lower piece of the sealing gasket. The structure of the gasket is simple and smartly designed and the punched bosses ensures the reliability of sealing, so the gasket better meet the requirements of increasingly strict laws and regulations; the uniformly distributed pawls make the installation of the gasket easy and positioning of the gasket accurate; and the up and down two layer structure helps to save soft material such as graphite or mica sheets used in the conventional gasket, and the gasket can be manufactured easily at low cost.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

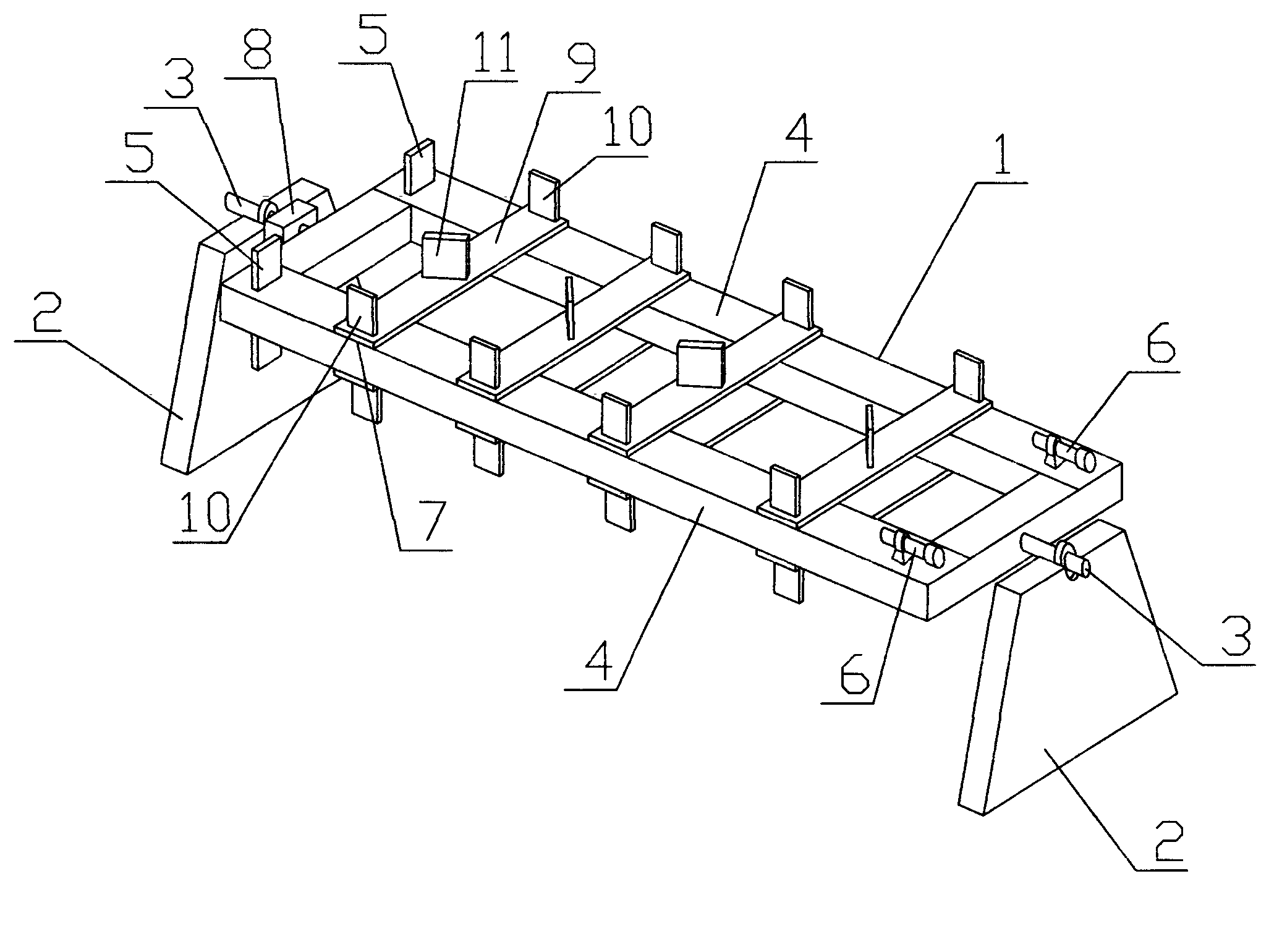

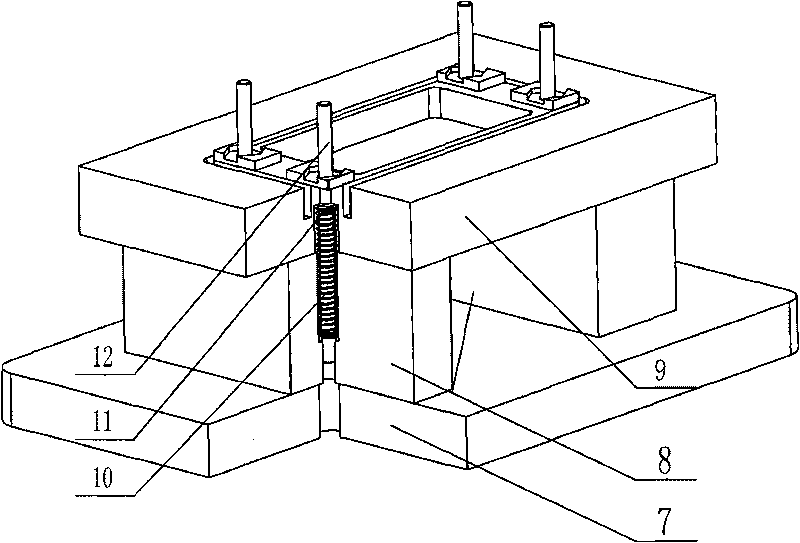

Truss assembling tool

InactiveCN103846594AAssembly positioning is accurateImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a truss assembling tool which comprises a tool main body and two brackets, wherein rotating shafts are arranged at two ends of the tool main body; the two brackets are symmetrically arranged; the rotating shafts are mounted on the corresponding brackets through bearings; the tool main body comprises two parallel cross beams; a main baffle is arranged at one end of each of the cross beams; puller bolts are arranged at the other end of each of the cross beams; a plurality of fixing devices are mounted between the two cross beams. The truss assembling tool can be used for fixing and connecting an upper chord, a lower chord and a web rod of a truss; assembling and positioning are accurate; the processing precision is high; the labor is saved; the labor cost is low; components of the truss can be fixed on the upper sides and the lower sides of the cross beams; the tool main body can rotate, so that the mounted truss can be rotated to the lower side so as to be directly dismounted; the processing period is short, and the working efficiency is high; connection plates of the fixing devices are connected with the cross beams through bolts, so that the fixing devices are detachable; the fixing devices of different specifications can be arranged on the truss assembling tool according to the style of the truss to be processed, and the use expansibility is high.

Owner:QINGDAO XINGUANGZHENG STEEL STRUCTURE MATERIAL

Cylinder liner spinning and flanging processing method and special fixture thereof

InactiveCN1544176AEasy to processReduce labor intensityCylinder headsCylindersEngineeringMechanical engineering

The invention discloses a cylinder case rotary pressing-curling processing method and its special clamp, and the method: installing and griping the cylinder case in the clamp and rotating the clamp, adopting a rotary pressing wheel to expand and press the mouth of the cylinder case to form a 120-150 degree bellmouthing, adopting an extrusion wheel to planish the big platform, loosening the cylinder case griped by the clamp and then ejecting the cylinder case and completing the processing, where the special clamp is a clamp: there is a space between the inner and outer bodies, the diameter of one side of the outer body is greater than that of the other side, there is a push-remove case between the inner and outer bodies on one end of the clamp and there is a conical stopper on the other end of the clamp, there is a pull rod set in the center of the inner body, and the pull rod is connected with the conical stopper. It has the characters of simple processing procedures, accurate assembly and positioning, high processing precision, high working efficiency and low labor strength.

Owner:烟台万斯特有限公司

Suspended ceiling keel sheet assembling and hoisting method

InactiveCN102022003AReduce riskAssembly positioning is accurateBuilding material handlingEngineeringLifting equipment

The invention relates to the field of installation of steel structures, in particular to a suspended ceiling keel sheet assembling and hoisting method. The suspended ceiling keel sheet assembling and hoisting method comprises two steps of assembling on ground and hoisting to elevation, and is characterized in that: in the process of assembling on the ground, primary and secondary suspended ceiling keels under a high-altitude net rack are vertically projected to a horizontal plane and then are assembled; and in the process of hoisting to elevation, lifting equipment is started to lift the suspended ceiling keels to the elevation, and then connecting rods for the suspended ceiling keels are fixedly connected with the net rack. The method reduces the risk in the process of mounting a high-altitude scaffold, and is accurate in positioning and higher in mounting speed.

Owner:MCC5 GROUP CORP SHANGHAI

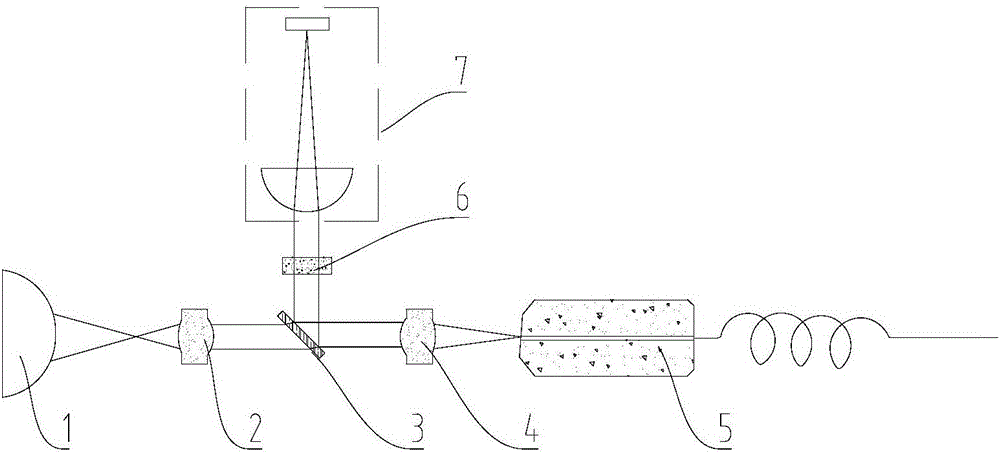

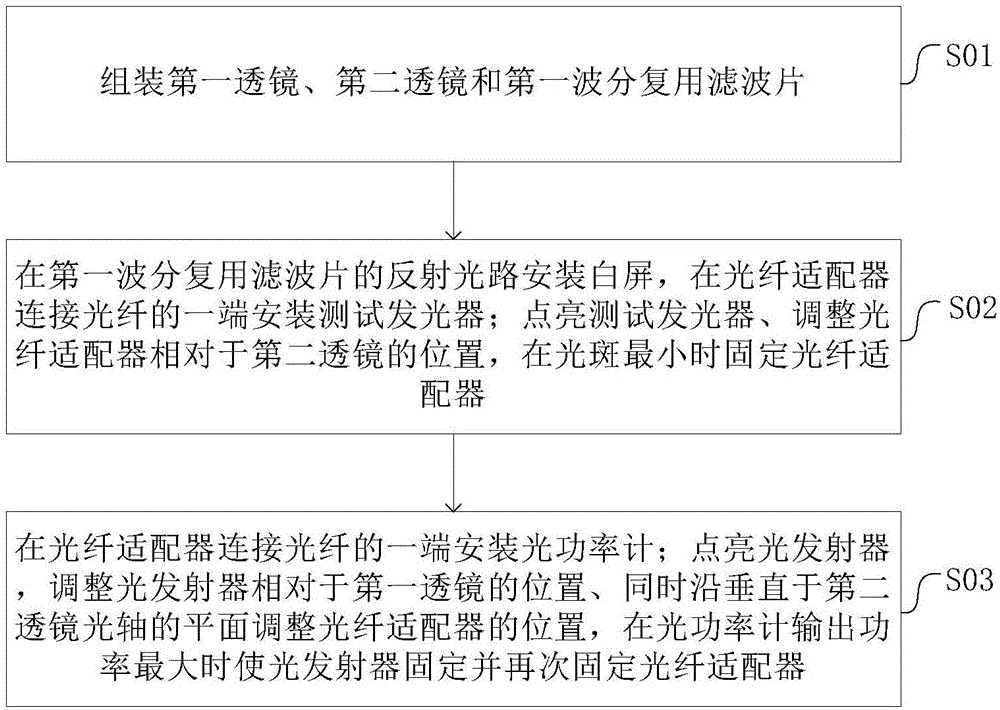

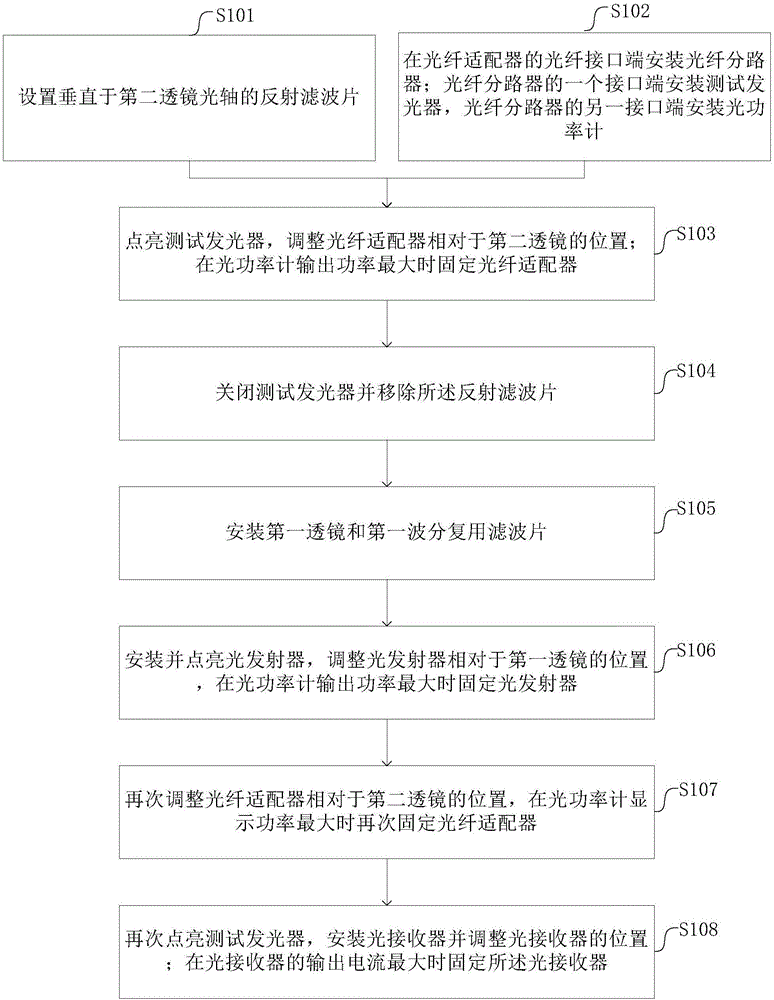

Optical transceiver module assembling method

ActiveCN106371177AAssembly positioning is accurateImprove transmission efficiencyCoupling light guidesWavelength-division multiplexingLight Testing

The invention provides an optical transceiver module assembling method. The method comprises the following steps: a reflection filter vertical to the optical axis of a second lens is arranged; an optical fiber splitter is arranged at an optical fiber interface end of an optical fiber adapter, one interface end of the optical fiber splitter is provided with a test illuminator, and the other interface end of the optical fiber splitter is provided with an optical power meter; if test light emitted by the test illuminator passes through the second lens and is then parallel with the optical axis of the second lens, the reflection filter totally reflects the test light; the test illuminator is turned on, the position of the optical fiber adapter relative to the second lens is adjusted, and the optical fiber adapter is fixed when the output power of the optical power meter is maximum; the test illuminator is turned off and the reflection filter is removed; a first lens and a first wavelength division multiplexing filter are arranged; and a light emitter is arranged and turned on, the position of the light emitter in relative to the first lens is adjusted, and the light emitter is fixed when the output power of the optical power meter is maximum.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

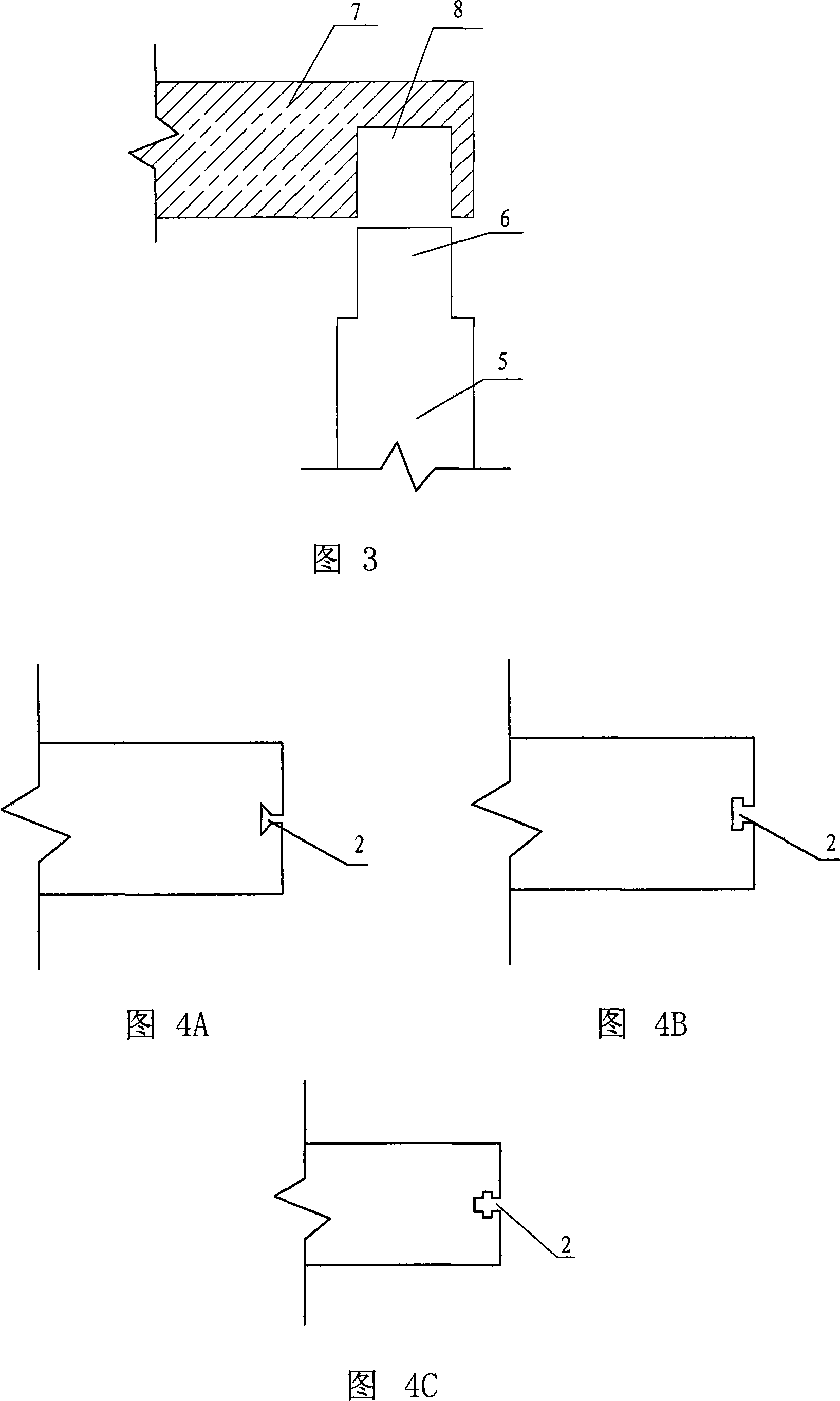

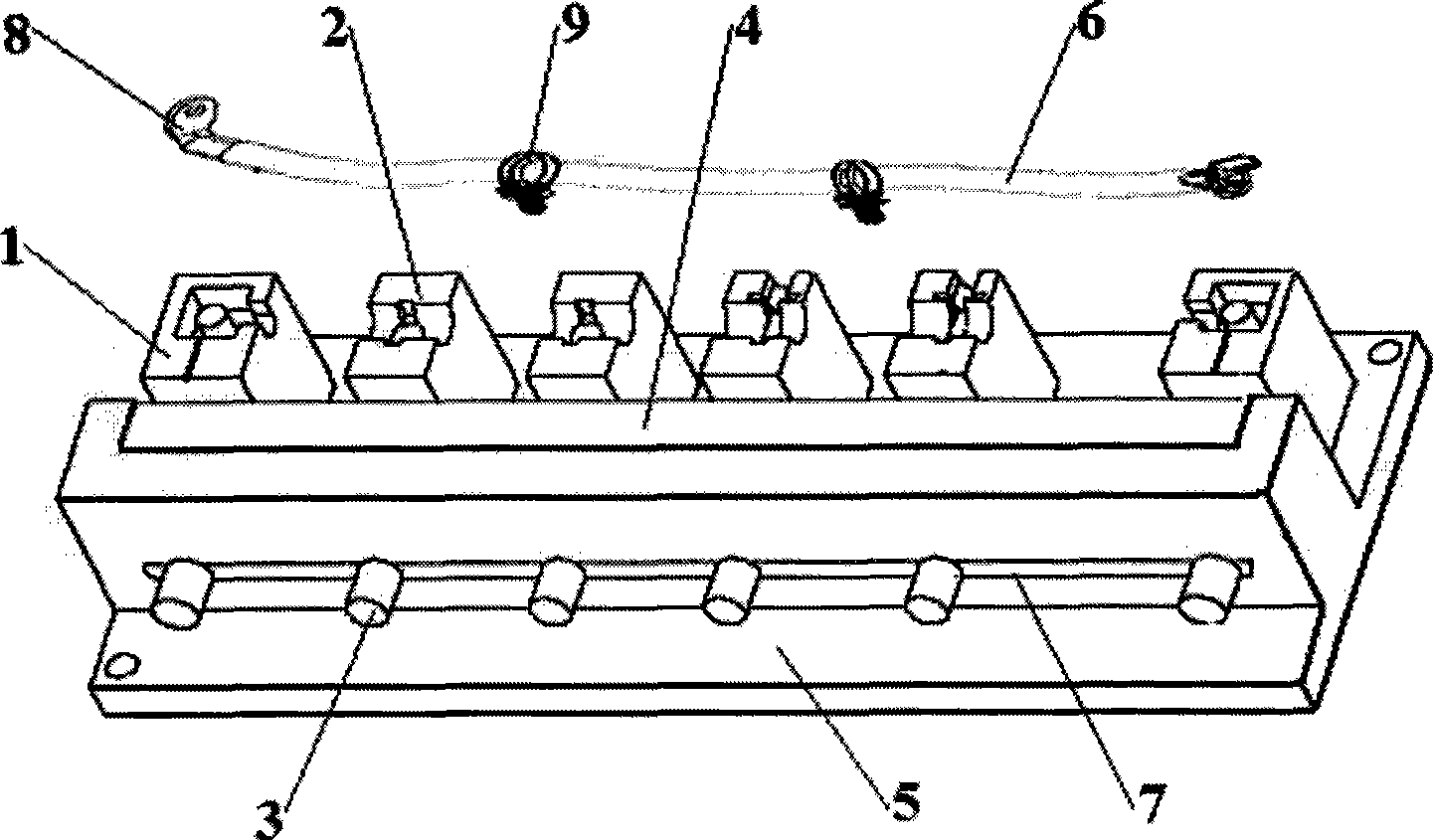

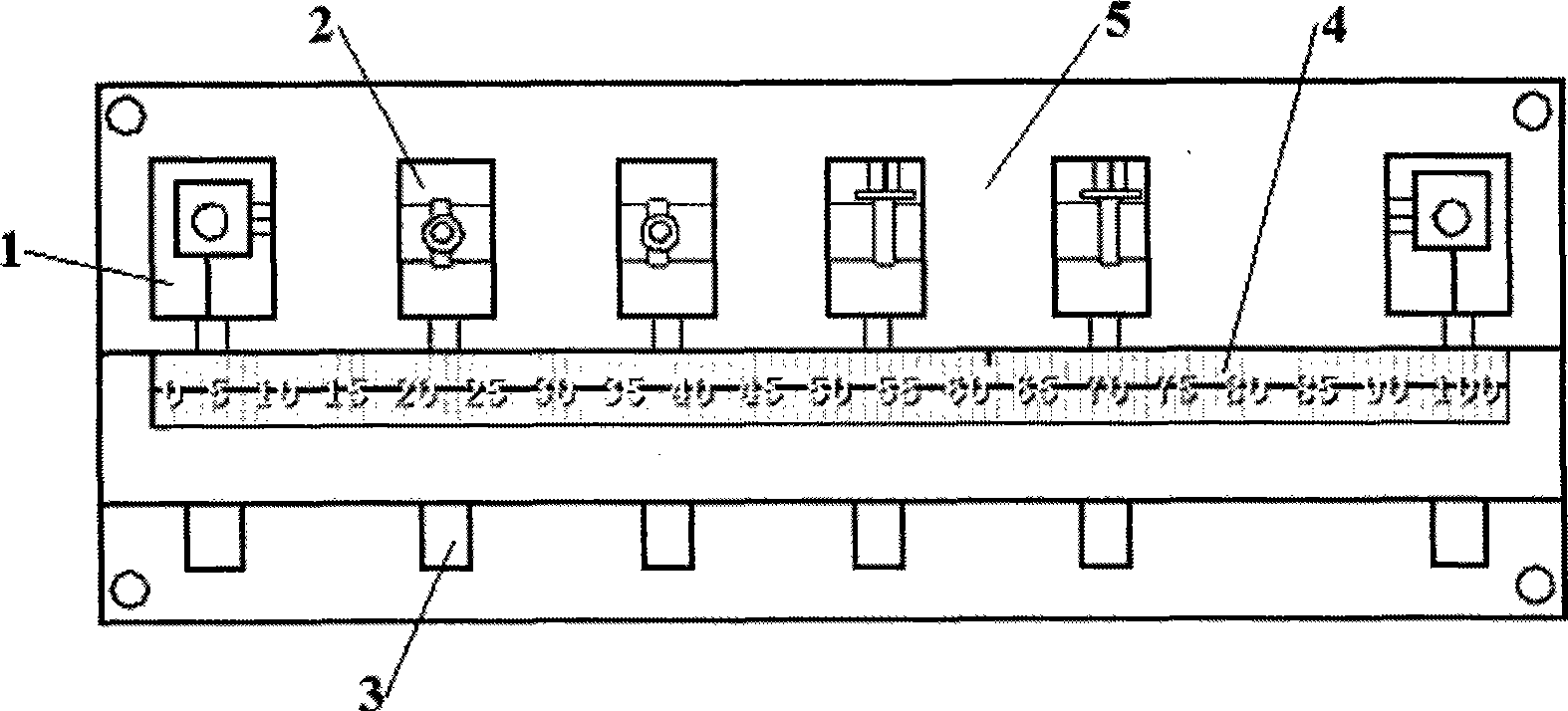

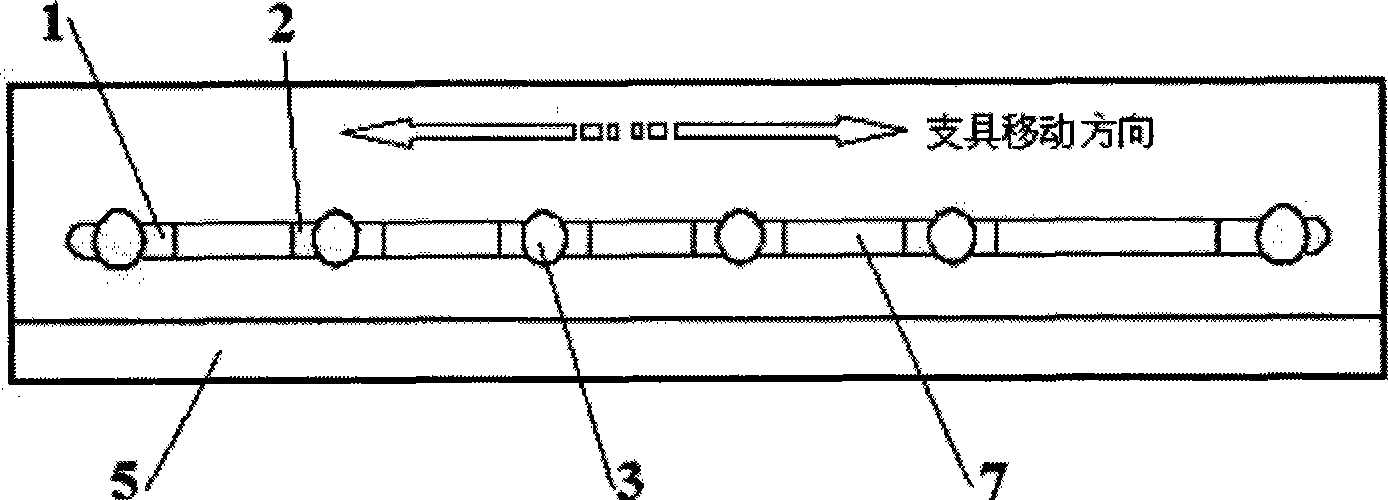

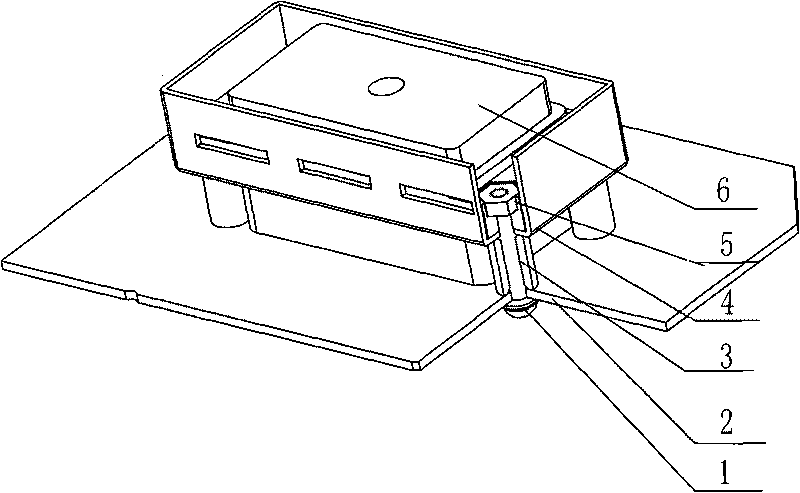

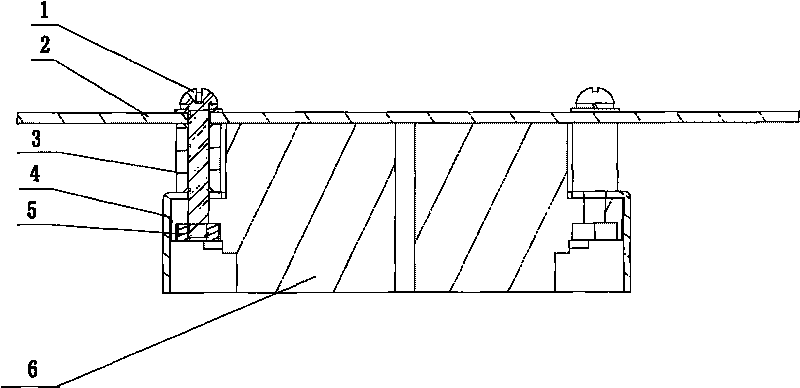

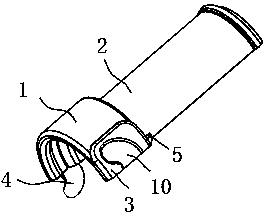

Assembling tool setup for automobile bunch product

InactiveCN101436763ARealize adjustableEasy to processCable installation apparatusEngineeringCable harness

The invention discloses an assembling frock of an automobile wiring harness product. The assembling frock comprises a main frock body (5) and a wiring harness fixing brace (1); a concave type for fixing a wiring harness terminal (8) is arranged on the wiring harness fixing brace (1); the assembling frock is also provided with an accessory fixing brace (2); a concave type for fixing a wiring harness accessory (9) is arranged on the accessory fixing brace (2); and the accessory fixing brace (2) is fixed on the main frock body (5) through a fastening bolt (3). The technical scheme changes the structure that the positions of the prior frock and the brace are fixed and can not be adjusted, realizes free adjustment between the brace and a frock plate, and can replace the accessory brace and move the position of the brace at any moment according to the condition of the wiring harness. The structure has the advantages of simple processing and manufacturing, convenient operation control, easy realization, low production cost, accurate assembling and positioning and stable product quality.

Owner:WUHU EXCELLENCE WIRE HARNESS SYST

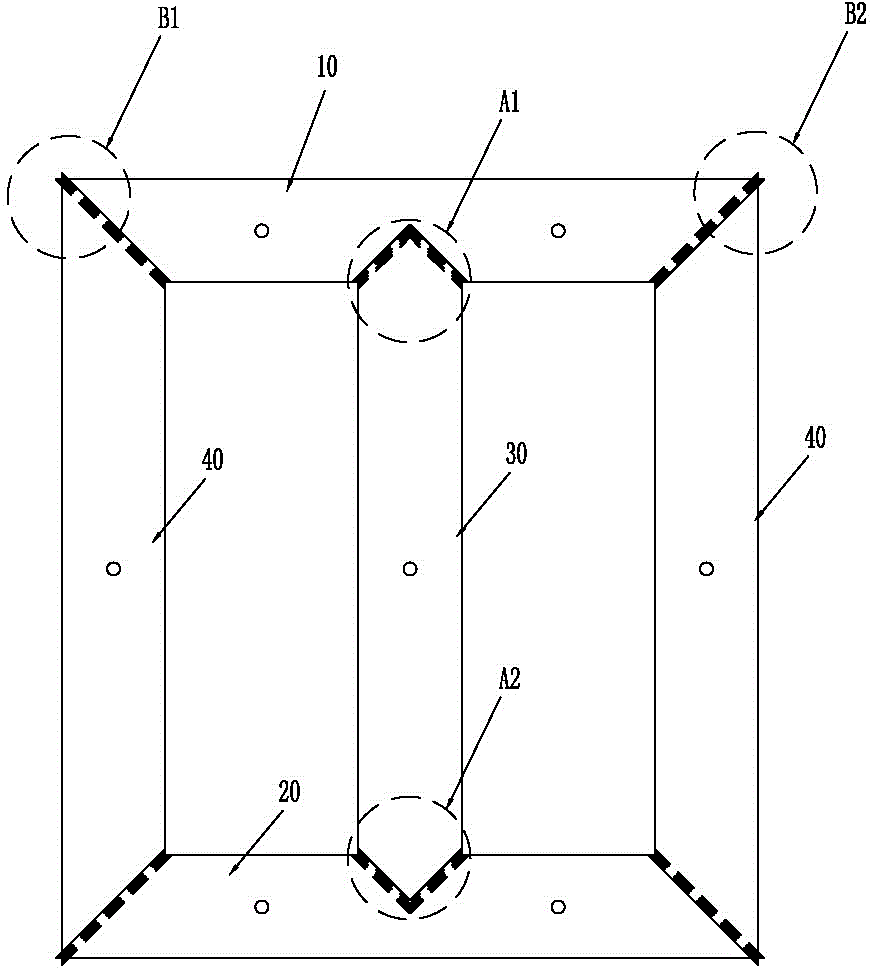

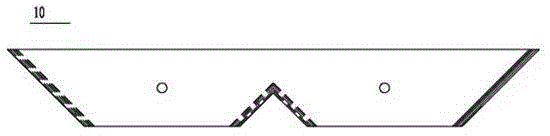

Transformer iron core capable of improving assembly efficiency

ActiveCN104810140AImprove product qualityReduce lossesTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

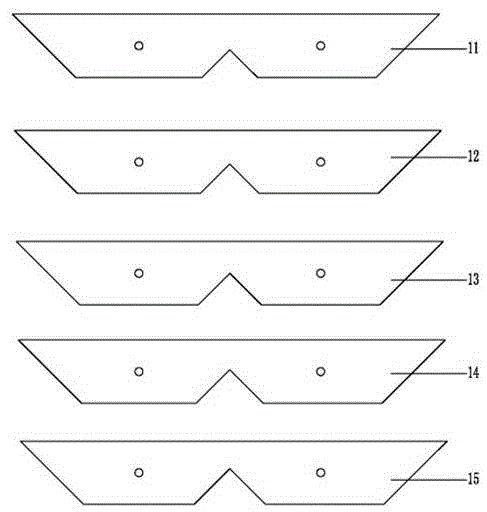

The invention relates to a transformer iron core capable of improving the assembly efficiency. The transformer iron core comprises one or more sequentially overlaid laminated layers, wherein each of the overlaid laminated layers comprises upper yoke laminates, lower yoke laminates, middle pillar laminates and side pillar laminates on two sides which are the same in number of laminates; the upper yoke laminates comprise one or more than one upper yoke piece, a triangular notch is formed in the middle section of the upper yoke piece, and the triangular notch on each upper yoke piece is longitudinally misplaced and stepped along the central line of the triangle; the left side end edge of each upper yoke piece is transversely misplaced and is longitudinally overlapped with the side pillar laminate and the middle pillar piece to step; the upper and lower ends of each of the middle pillar pieces of the middle pillar laminate respectively form triangular parts and are longitudinally misplaced and stepped; the upper and lower end edges of the side pillar piece of the side pillar laminate on each side obliquely extend and are longitudinally misplaced and longitudinally overlapped with the upper and lower yoke pieces to step; process holes convenient for assembling and positioning are formed on the upper and lower yoke pieces, the middle pillar pieces and side pillar pieces. The transformer iron core provided by the invention is simple to operate and convenient to assemble, the assembly efficiency is improved and the labor cost is lowered.

Owner:DONGGUAN GUANGHUA IND

Assembling positioning device for car oil filler cap

InactiveCN105416410AAssembly positioning is accurateGuaranteed clearanceSuperstructure subunitsPositioning systemAutomotive engineering

The invention discloses an assembling positioning device for a car oil filler cap and belongs to the field of motor vehicle assembling. The assembling positioning device comprises a first positioning body and a second positioning body fixedly connected with the first positioning body. The first positioning body is positioned on a side wall outer plate at a car oil filler and used for positioning the assembling positioning device in the left-right direction, the front-back direction and the up-down direction of a car. The second positioning body is connected with a car oil filler cap assembly and used for positioning the car oil filler cap assembly in the front-back direction of the car. The assembling positioning device for the car oil filler cap comprises a positioning system mounted on a car body and an oil filler cap assembling positioning system, so that the car oil filler cap assembly is accurately positioned on the car body, assembling is completed by fastening bolts at a time, and time and labor are saved; meanwhile, design of car body parts and design of the oil filler cap assembly do not need any change, and therefore the assembling positioning device can be applied to both developed cars in production and cars in development and design.

Owner:CHERY AUTOMOBILE CO LTD

Complete separated type anti-bending bundle inclined strut

InactiveCN101302778ASimplify filling construction workMonitor production qualityShock proofingQuality assuranceCement mortar

The invention relates to a completely separated type buckling restrained diagonal brace. Aiming at eliminating the defects of difficult production and inconvenient assembly and construction in the existing buckling restrained diagonal braces, the completely separated type buckling restrained diagonal brace is provided by the invention. According to the invention, the primary is that a confinement component is divided into more than two separated groove-shaped member materials so as to ensure that fillings, such as concrete or cement mortar, etc., can be precast to mold in the filling groove of the groove-shaped member material, and each groove-shaped member material covers and is fixedly combined on a supporting component to form a confinement, thus effectively utilizing the buckling restrained diagonal brace which is assembled by completely separated components and applied to buildings or the civil engineering so as to improve the quality assurance monitoring, practicability and performance of the buckling restrained diagonal brace.

Owner:蔡崇兴

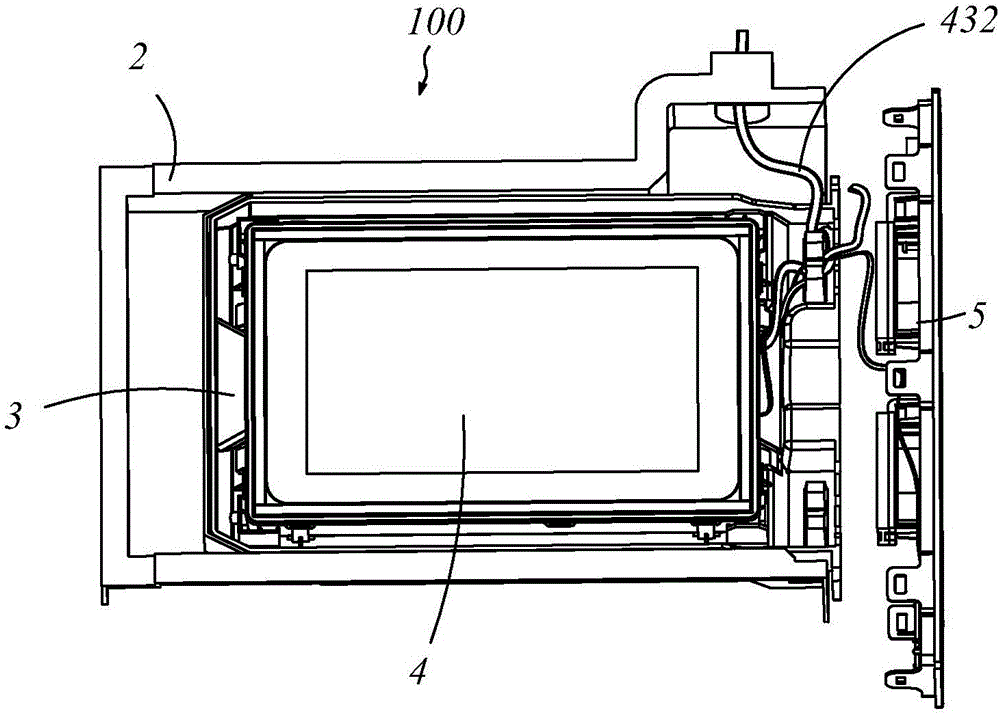

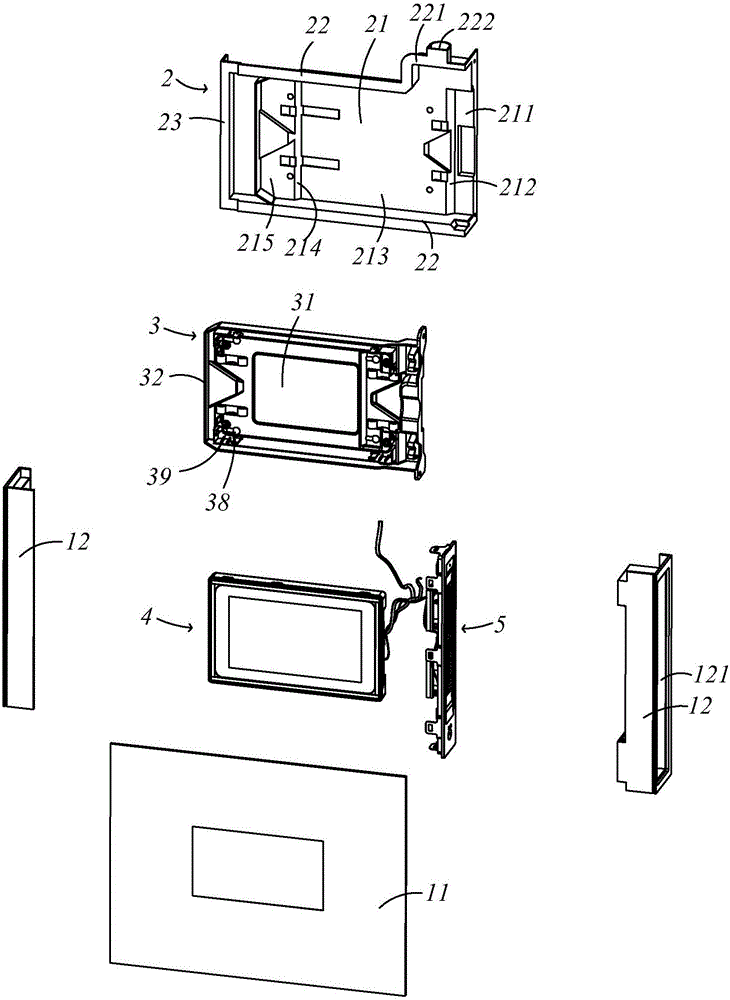

Display screen assembly and refrigeration household appliances

ActiveCN106205377AAssembly positioning is accurateAvoid shakingLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention provides a display screen assembly, which comprises an embedded box, an installing support frame, a display screen module and a cover plate assembly, wherein the display screen is positioned in the display screen module. The display screen assembly is characterized in that the embedded box comprises a fixed wall, a pair of side walls, a connecting wall and an opening; the fixed wall, the side wall and the connecting wall simultaneously define an installing groove; the installing support frame comprises a support wall and a peripheral wall; the display screen assembly also comprises a positioning mechanism which is arranged on the embedded box and the installing support frame in a matched way; the positioning mechanism comprises a first positioning triangle, a second positioning triangle, a first guide triangle and a second guide triangle; the first positioning triangle is positioned on the fixed wall and near the opening position; the second positioning triangle is positioned on the fixed wall and near the connecting wall position; the first guide triangle and the second guide triangle are positioned on the installing support frame; the first positioning triangle is recessed towards one side deviating from the side wall; the second positioning triangle is projected towards one side with the side wall. The installation and the positioning of the display screen assembly are precise.

Owner:HAIER SMART HOME CO LTD

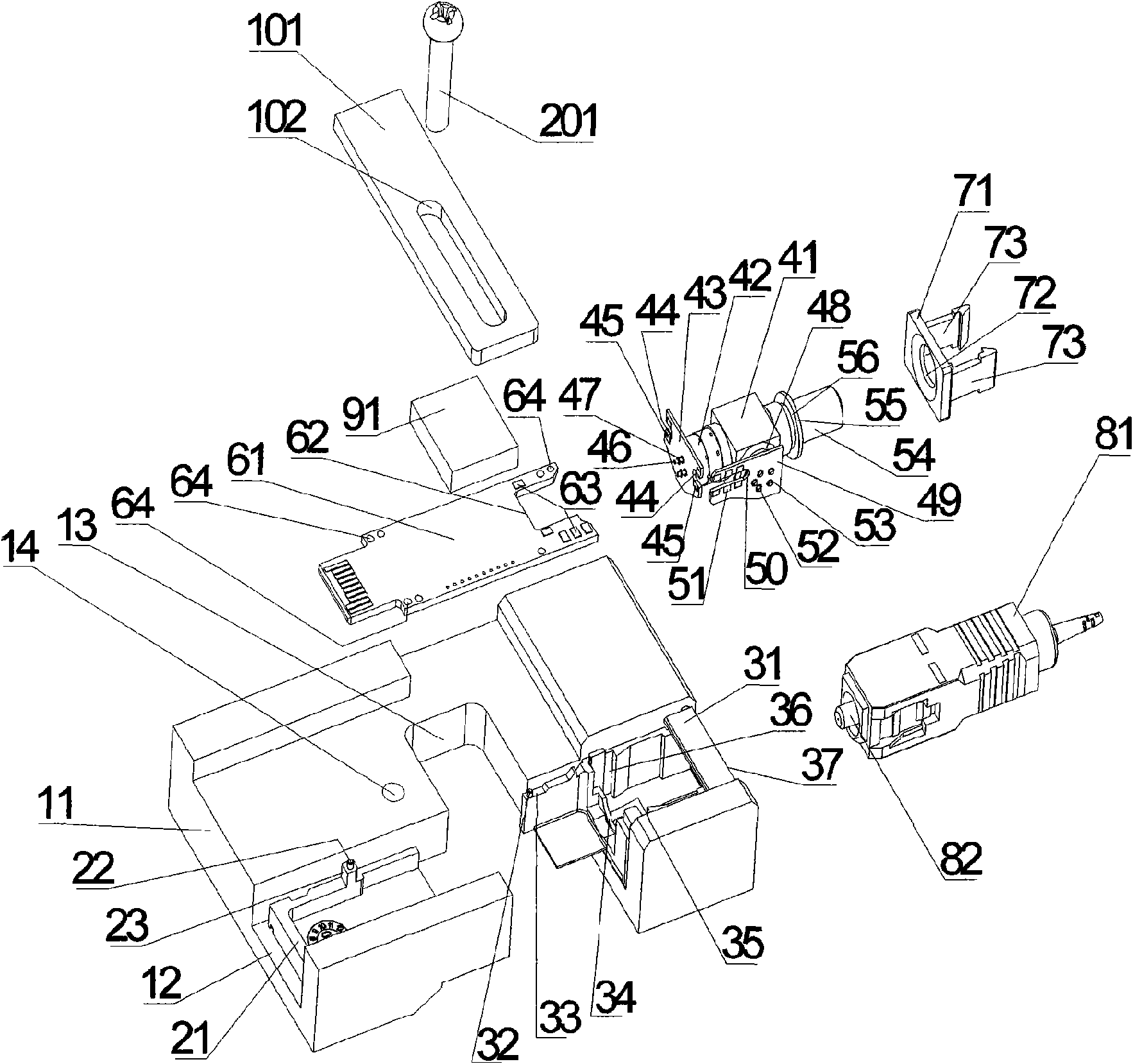

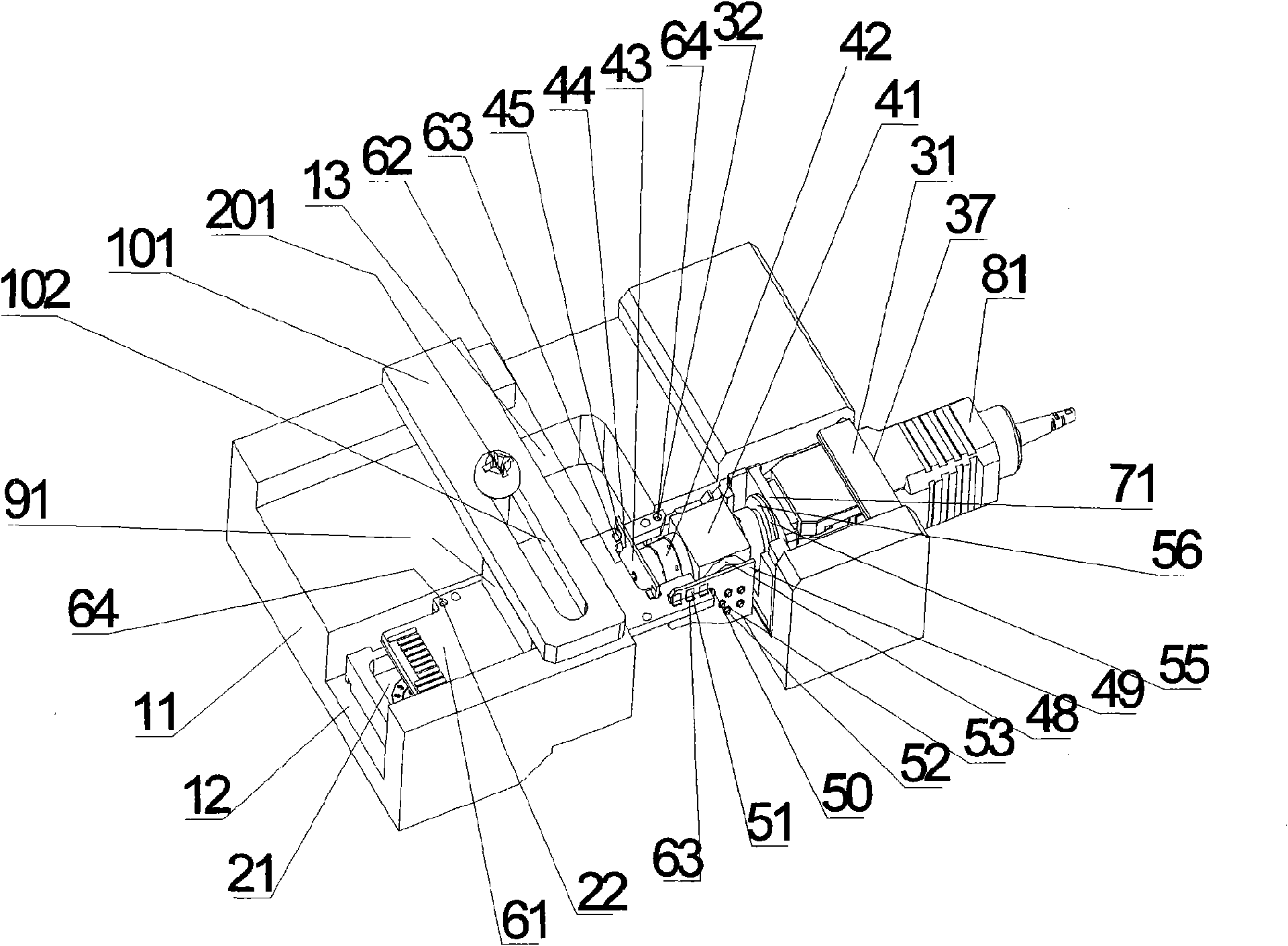

Shielded ultrasound probe socket and assembling jig thereof

ActiveCN101694483AAvoid hidden dangers such as poor contactAssembly positioning is accurateMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringUltrasound probe

The invention discloses a shielded ultrasound probe socket which comprises an ultrasound probe socket, an open ultrasound probe socket shielded box and an ultrasound probe socket circuit board, wherein the ultrasound probe socket is fixed on the ultrasound probe socket circuit board, and the open ultrasound probe socket shielded box surrounds the ultrasound probe socket. The shielded ultrasound probe socket also comprises screws, nuts and cylindrical support columns, wherein at least one nut clamping groove is respectively arranged at both ends of the ultrasound probe socket, the number of the screws, the nuts and the cylindrical support columns corresponds to the number of the nut clamping grooves, each nut is placed in each nut clamping groove, each cylindrical support column is positioned between the ultrasound probe socket circuit board and the open ultrasound probe socket shielded box, each screw passes through the through hole in the ultrasound probe socket circuit board, then passes through the cylindrical support column, and then passes through the through hole of the open ultrasound probe socket shielded box, and finally is screwed into the nut.

Owner:深圳蓝影医学科技股份有限公司

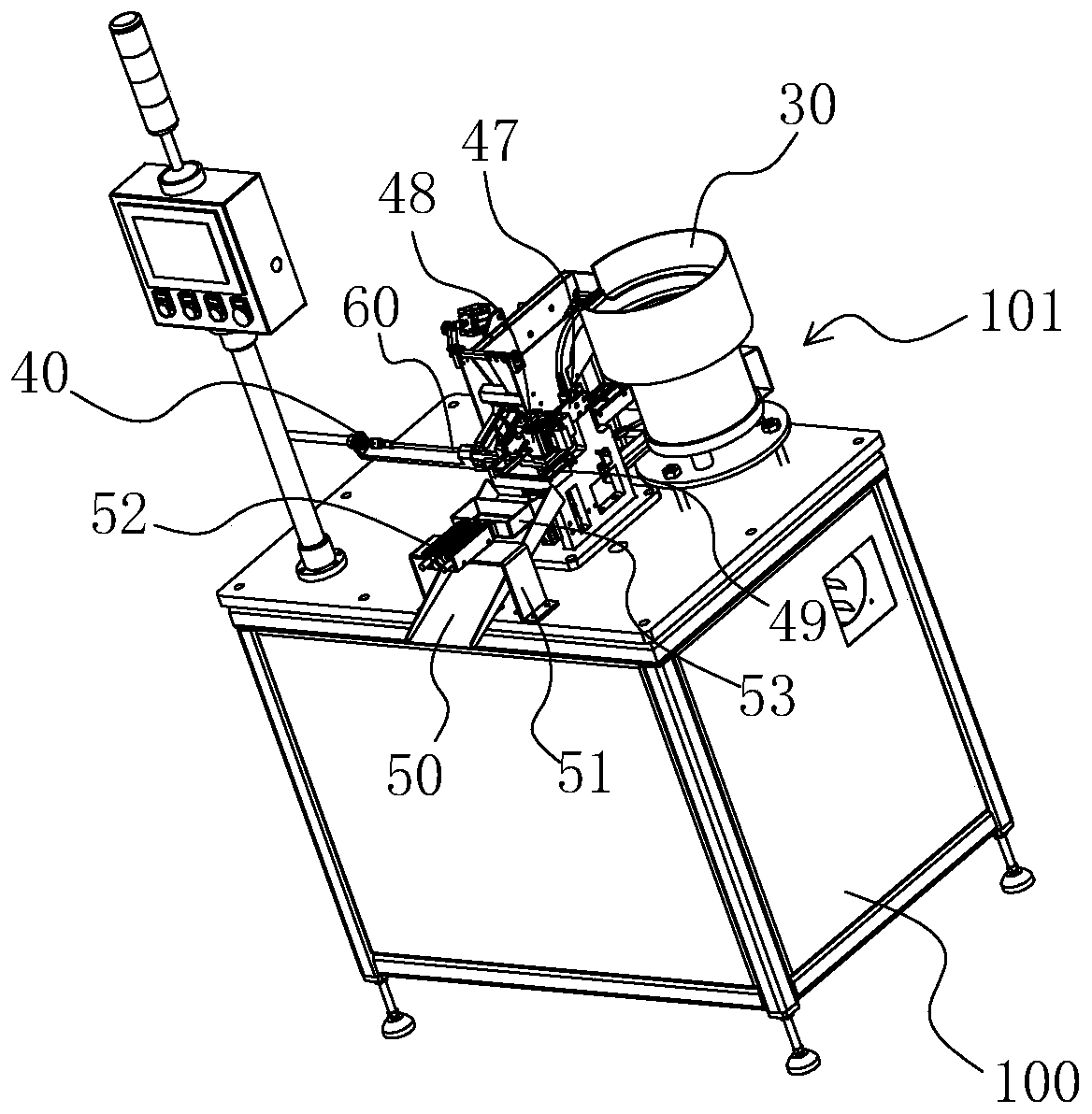

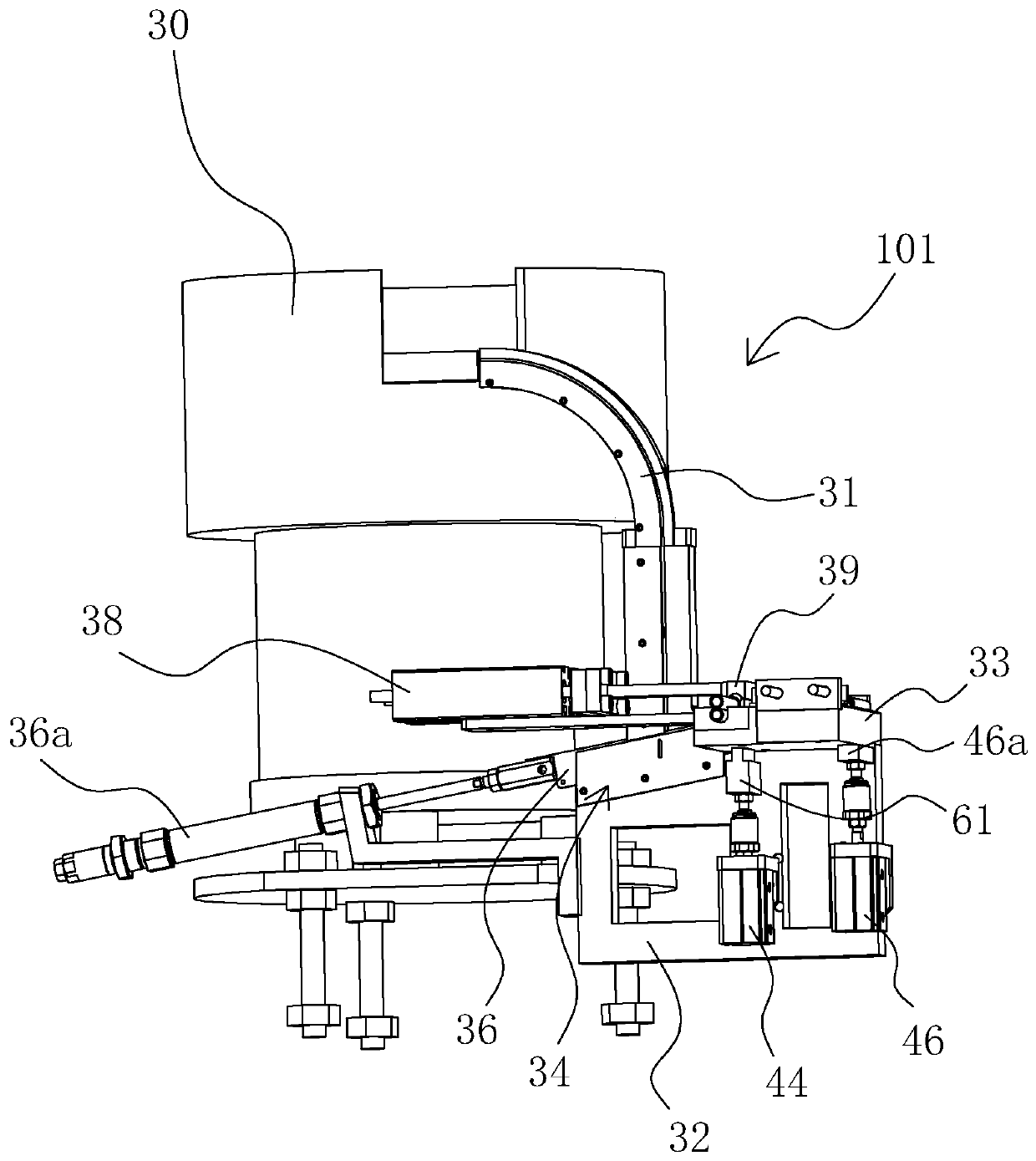

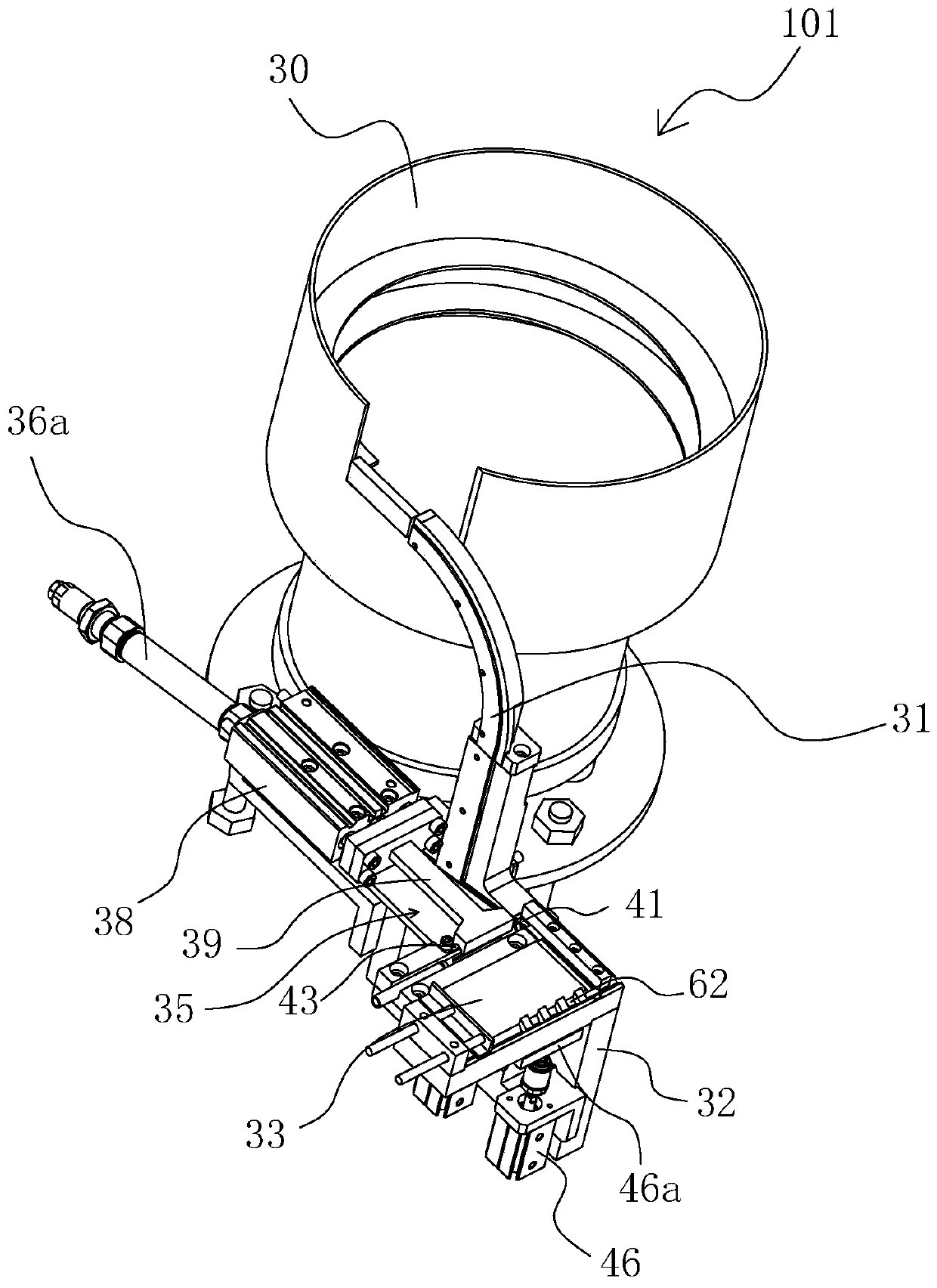

Welding ring sleeving machine

PendingCN110788587AReduce labor costsAssembly positioning is accurateMetal working apparatusManufacturing engineeringMaterial storage

The invention belongs to the technical field of automation equipment, and particularly relates to a welding ring sleeving machine. The welding ring sleeving machine includes a worktable. The workableis provided with a material storage box. The interior of the material storage box is provided with an abutting adjusting plate capable of moving in a straight line reciprocating mode along the horizontal direction. The interior of the material storage box is provided with a shifting pipe rotating plate. The welding ring sleeving machine enables position deviation not to occur on copper pipes in the sliding process by arranging and adjusting the abutting adjustment plate. Meanwhile, through arrangement of the shifting pipe rotating plate, the copper pipes located above the material storage boxcan slide down in order to prevent the copper pipes above from being clamped. The welding ring sleeving machine has an automatic sorting function, and can limit the height of the copper pipes by a pipe pressing article, so as to avoid the simultaneous discharge of two layers of copper pipes. The welding ring sleeving machine has no need for manual sorting and reduces labor cost. Finally, ring feeding, sleeving and assembling are carried out on the copper pipes through a ring feeding and assembling mechanism. The assembling positioning is accurate, the automation degree is high, the manual ringsleeving is not needed and the production efficiency is high.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

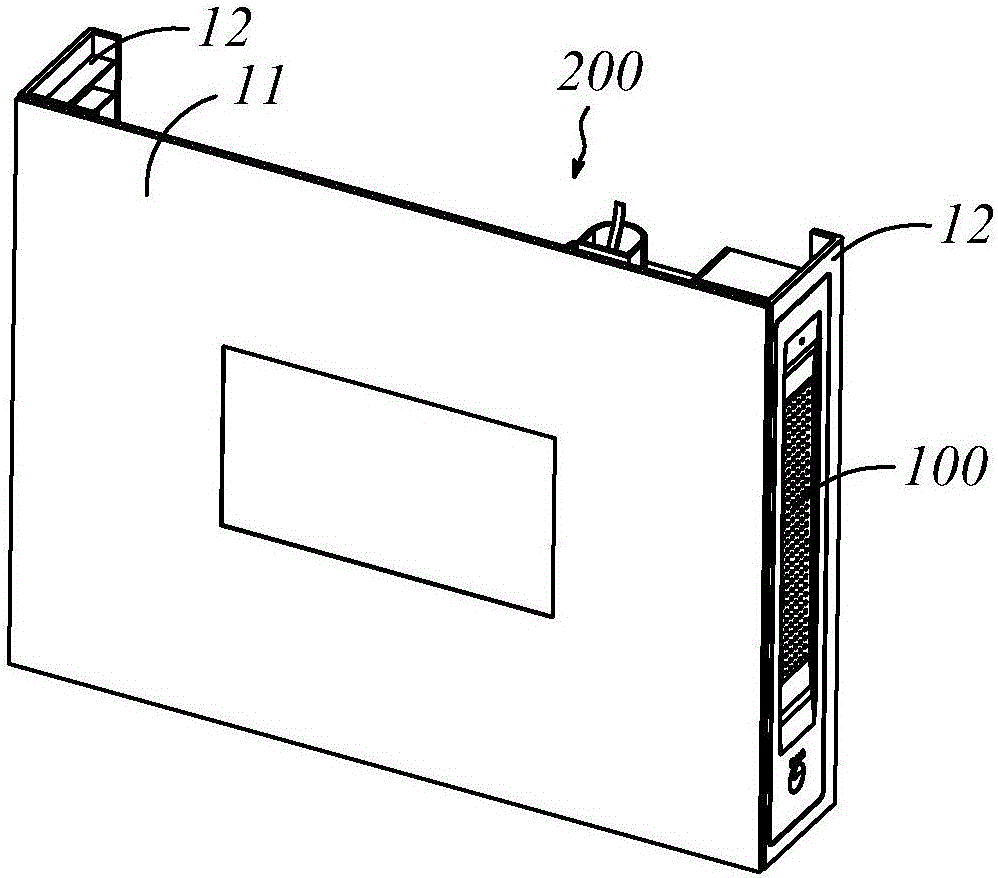

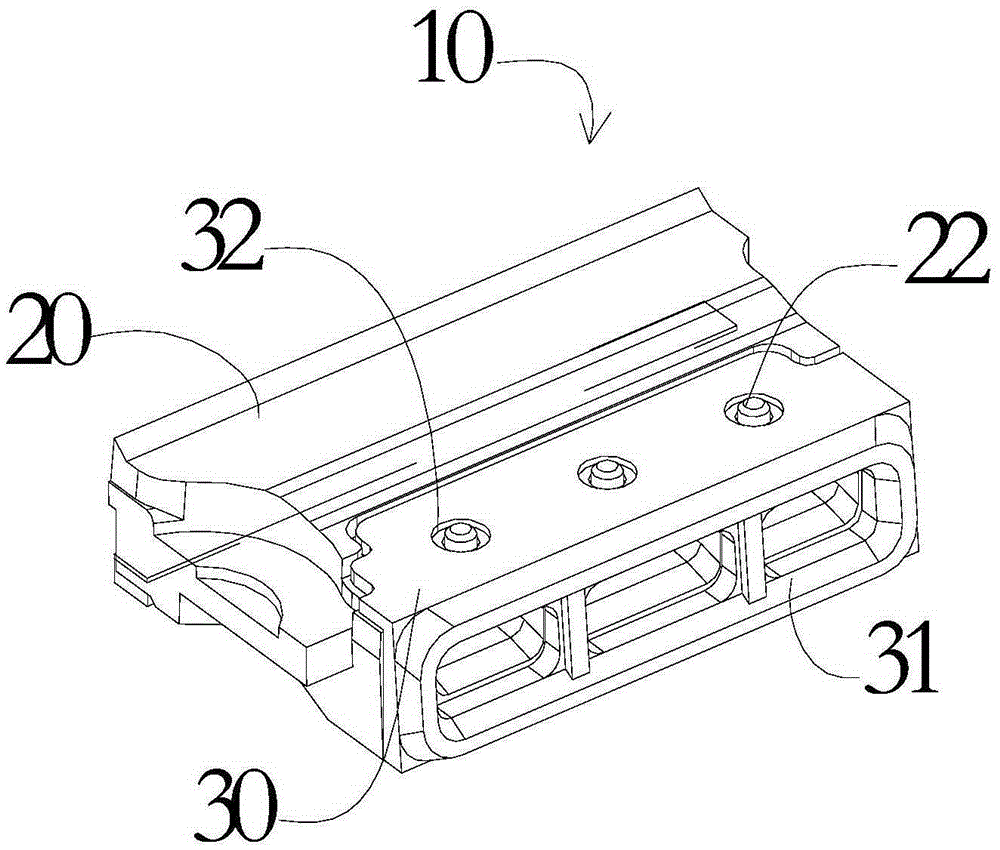

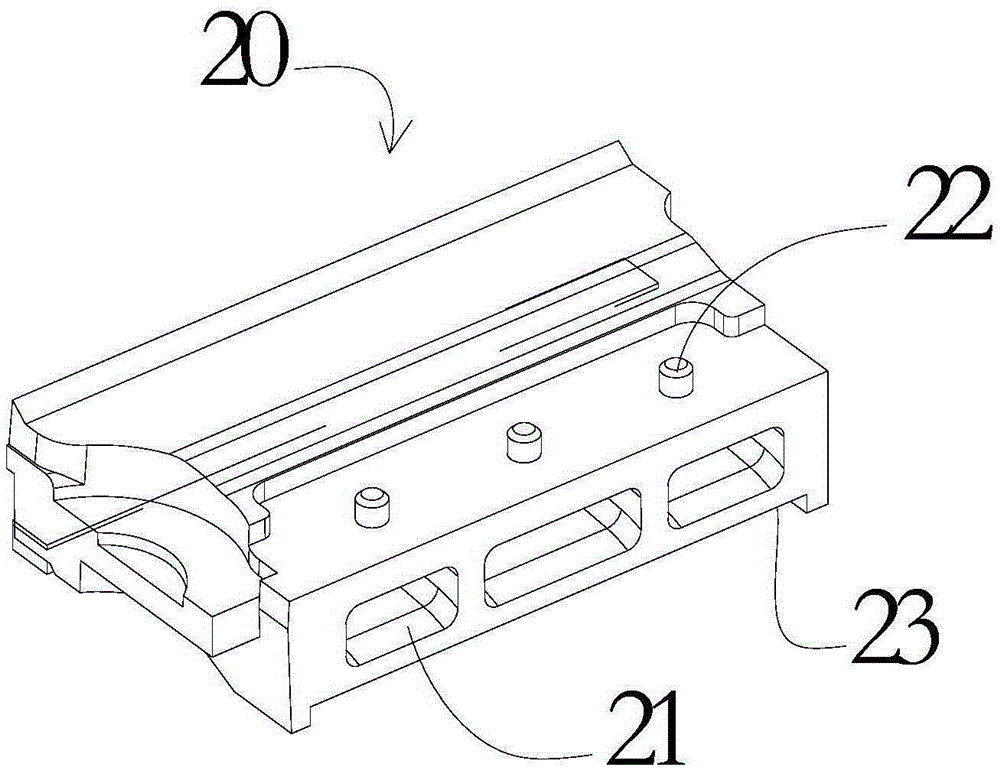

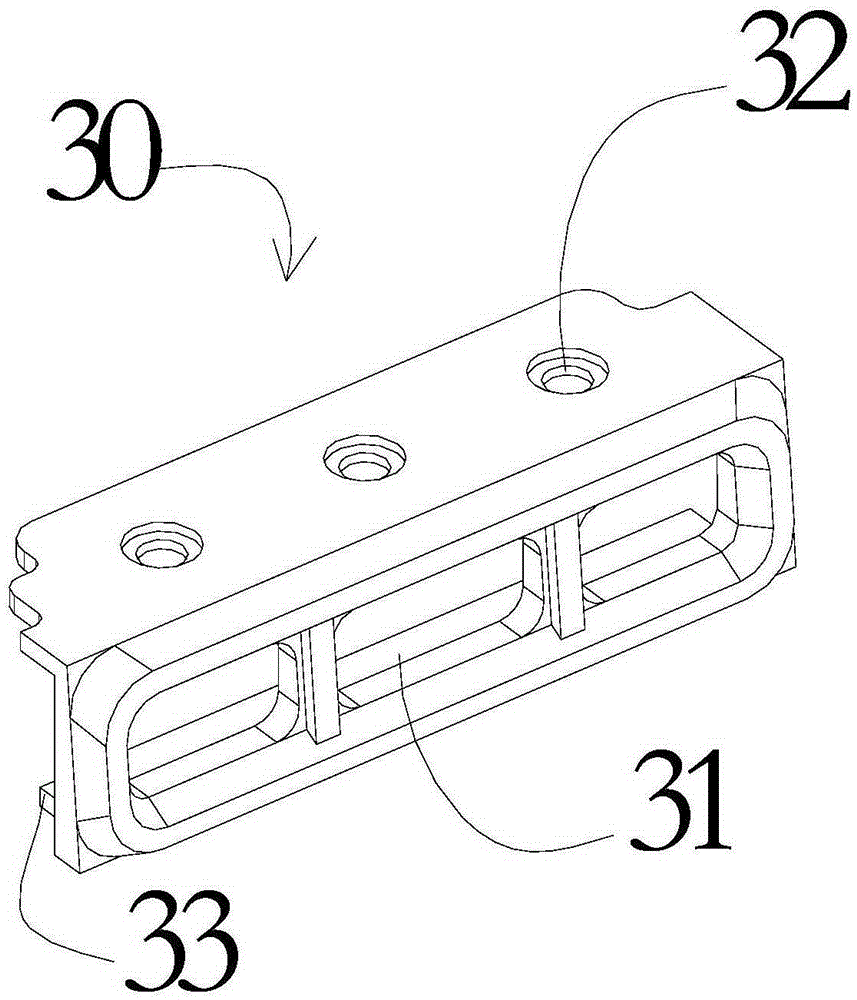

Sound cavity structure and mobile terminal

ActiveCN105306655AAvoid prone spatula problemsAvoiding the Spatula ProblemSubstation speech amplifiersEngineeringComputer terminal

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

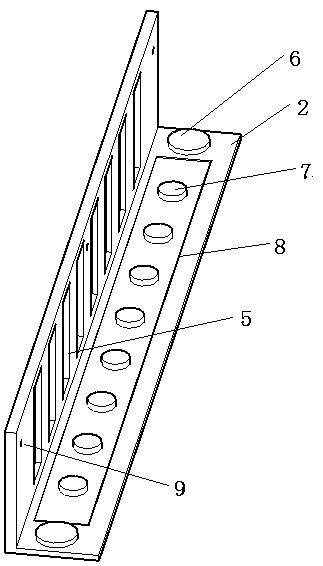

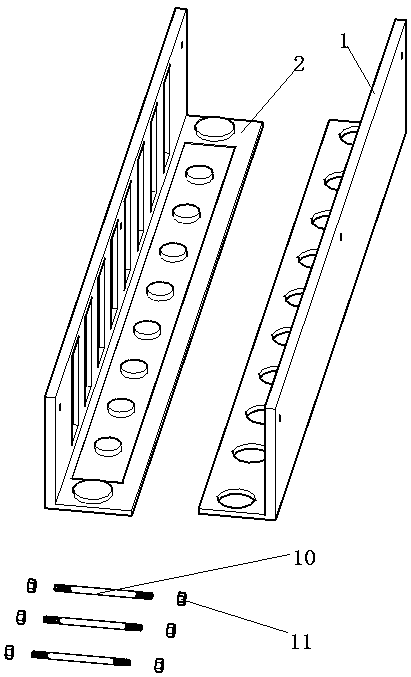

L-shaped open type permanent beam template

The invention discloses an L-shaped open type permanent beam template. The L-shaped open type permanent beam template comprises an L-shaped upper template body and an L-shaped lower template body; limiting holes are formed at both ends of the bottom surface of the L-shaped upper template body; limiting keys matched with the limiting holes are formed on the bottom surface of the L-shaped lower template body; a group of engaging holes are formed in the middle of the bottom surface of the L-shaped upper template body; a group of engaging keys matched with engaging holes are formed in the middle of the bottom surface of the L-shaped lower template body; the L-shaped lower template body is provided with a slurry permeating groove; and screw rods pass through screw rod holes in the side walls ofthe L-shaped upper template body and the L-shaped lower template body and are fixed by nuts. According to the invention, adverse factors of a conventional template can be improved, durability of thestructure is improved, an occupied space of the template is effectively reduced, and transportation cost is reduced.

Owner:南京彼卡斯建筑科技有限公司 +1

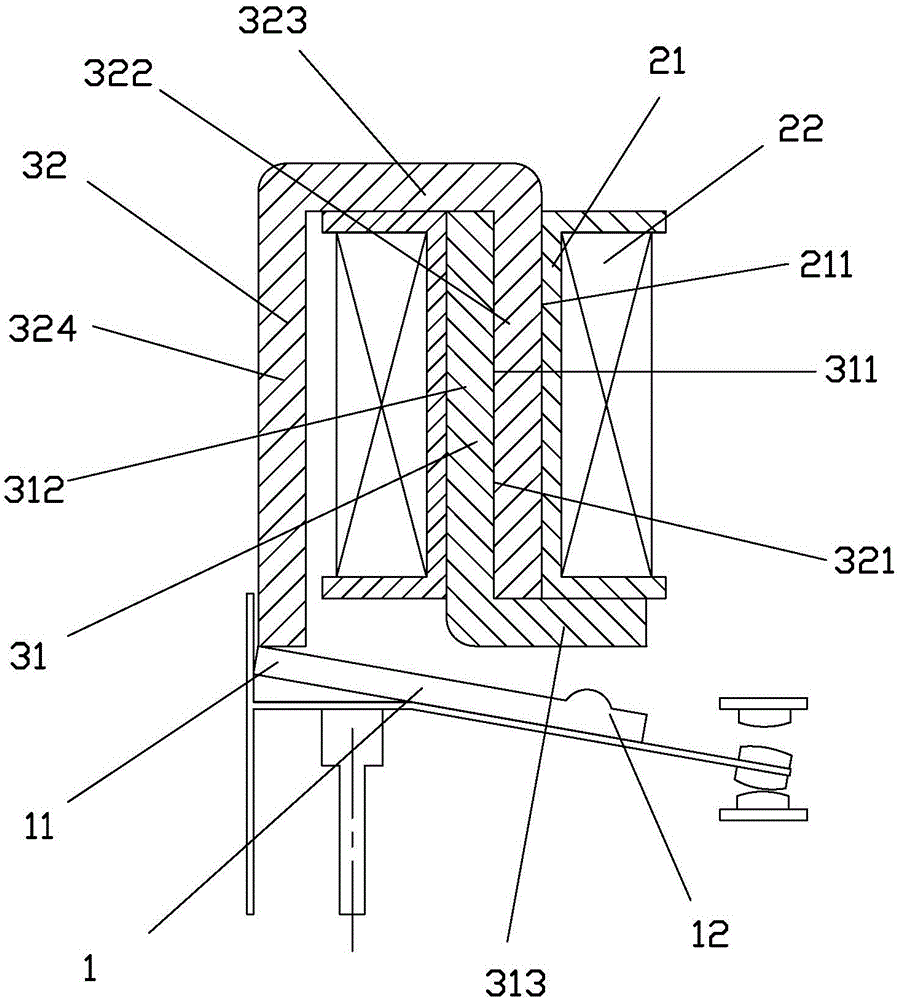

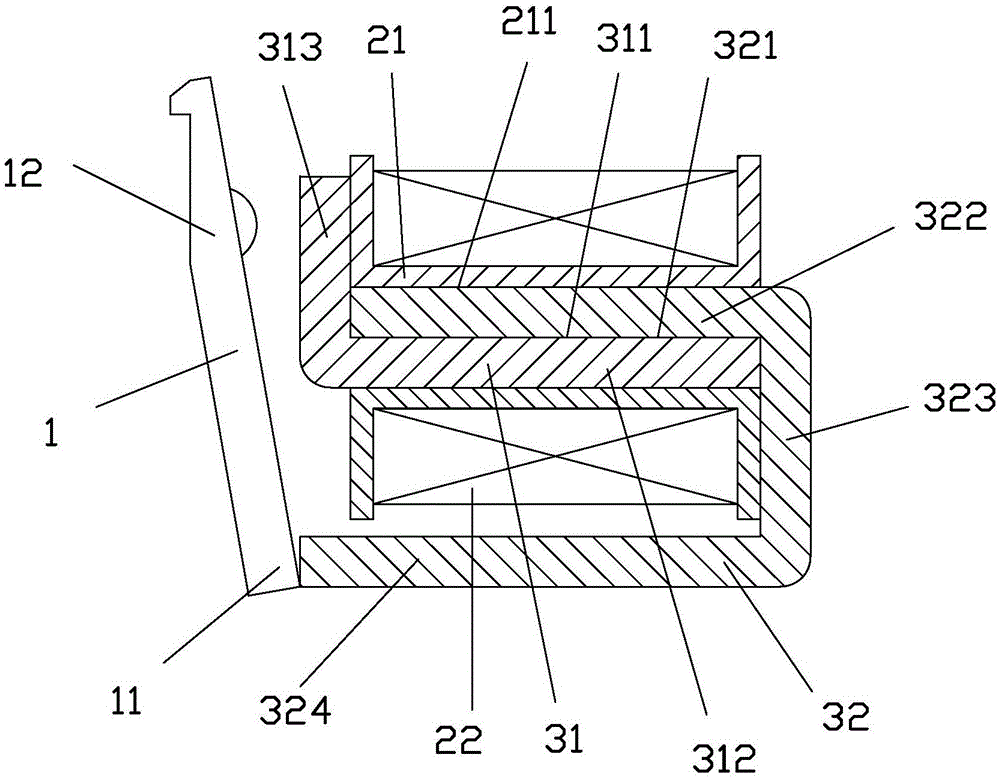

Electromagnetic circuit system and electromagnetic relay

ActiveCN105097360AIncrease contact areaStable flowElectromagnetic relay detailsRelayMagnetic circuit

The invention discloses an electromagnetic circuit system and an electromagnetic relay. The electromagnetic circuit system comprises a yoke iron, an armature and a coil, wherein the coil is composed of a coil rack and an enameled wire, the coil rack is provided with a through hole for installing an iron core, the yoke iron comprises an L-shaped yoke iron and a U-shaped yoke iron, one edge of the L-shaped yoke iron and one side edge of the U-shaped yoke iron are respectively and oppositely inserted into the through hole of the coil rack from the two ends of the through hole of the coil rack to prop against each other so as to form the iron core installed in the through hole of the coil rack, an end edge at other side edge of the U-shaped yoke iron serves as a knife edge for supporting one end of the armature, and the other edge of the L-shaped yoke iron serves as a pole surface for attracting the other end of the armature during working of the coil. By improving the yoke iron structure, the magnetic circuit system has the characteristics of high magnetic conductivity and excellent assembly process, the usage of the enameled wire can be effectively reduced, and product volume is reduced.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

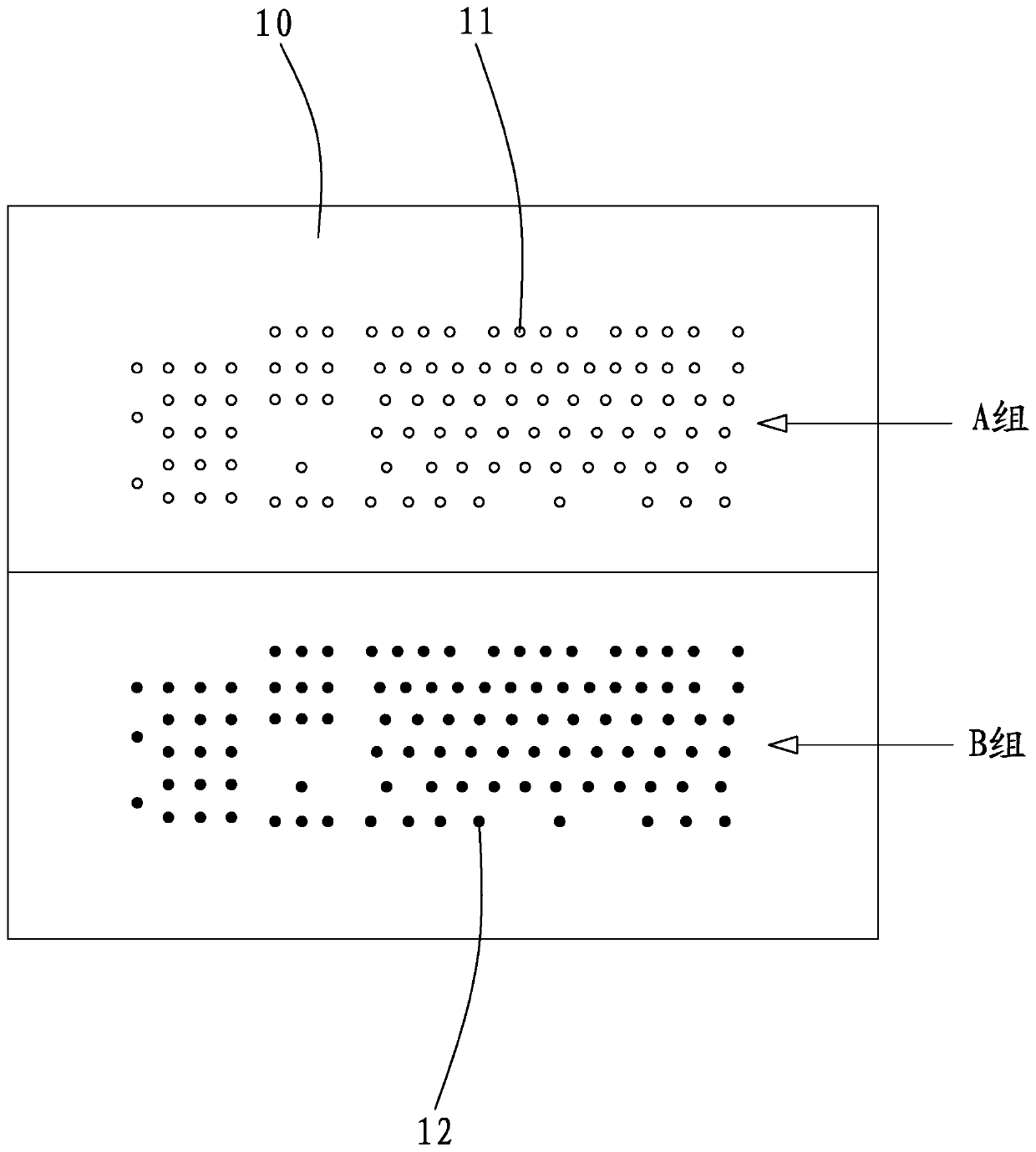

Method and device for realizing connection of optical transceiver and main printed circuit board

InactiveCN101646311AFirmly connectedAssembly positioning is accuratePrinted circuit assemblingPrinted circuit non-printed electric components associationTransceiverEngineering

The invention discloses a method and a device for realizing connection of an optical transceiver and a main printed circuit board. The receiving end pin and the transmitting end pin of the optical transceiver are respectively connected with a bridge connection printed circuit board; the side end of the bridge connection printed circuit board is provided with a U-shaped groove, and welding discs inparallel array distribution are arranged besides the U-shaped groove; one end of the main printed circuit board is provided with a C-shaped opening, and two ends of the C-shaped opening are manufactured with a connecting welding disc; the bridge connection printing circuit boards are inserted into two ends of the C-shaped opening of the main printed circuit board via the U-shaped groove to ensurethat the welding discs in parallel array distribution of the receiving end bridge connection printed circuit boards and the transmitting end bridge connection printed circuit boards are respectivelyaligned with the connecting welding discs on two ends of the C-shaped opening of the main printed circuit board, a base seat positioning component fixes the main printed circuit board, and a pressingcomponent tightly presses the main printed circuit board. The technical scheme of the invention can bring accurate assembly and positioning and reliable connection, greatly improve production efficiency and greatly lower production cost.

Owner:CHENGDU SUPERXON COMM TECH CO LTD

Cast iron and glass fiber composite double-layer structure cable protection sleeve

PendingCN110212465AAssembly positioning is accurateEasy to carryElectrical apparatusGlass fiberSalient point

The invention discloses a cast iron and glass fiber composite double-layer structure cable protection sleeve, which comprises a fat connection pipe, a thin connection pipe and a connection ring. The fat connection pipe and the thin connection pipe as well as the thin connection pipe and the connection ring are in integrated arrangement. The fat connection pipe, the thin connection pipe and the connection ring are internally equipped with an inner layer matched therewith. One side surface, close to the inner side wall of the thin connection pipe, of the inner layer is symmetrically provided with four clamping salient points. The inner side wall of the thin connection pipe is provided with clamping grooves matched with the clamping salient points. The clamping salient points are clamped in the clamping grooves respectively. Reinforcing ribs are symmetrically arranged between the fat connection pipe and the thin connection pipe. The thin connection pipe is arranged in a half-cylinder manner. One side wall of the cross section of the thin connection pipe is provided with an integrated locating pin. A single product is made of the same upper and lower components through a connecting lugself-locking structure without fastening, and thus fast and accurate assembly and positioning can be realized, and meanwhile, convenient carrying is achieved.

Owner:上海伟泰实业发展有限公司

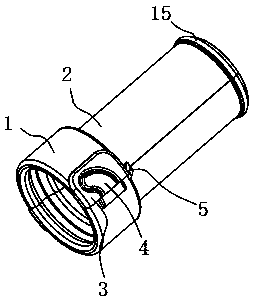

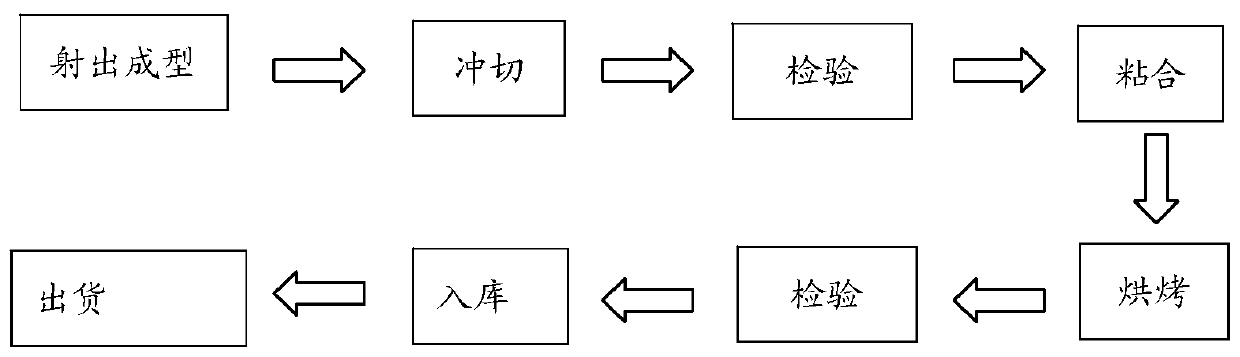

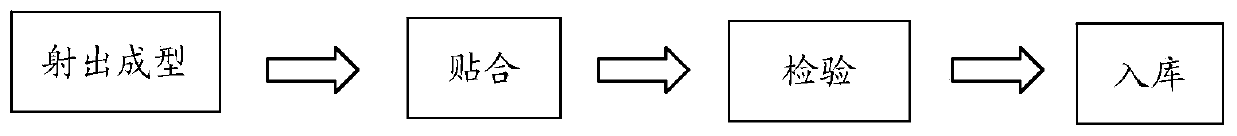

Production process of circuit board with silicone keys

InactiveCN109920680ASavingsAssembly positioning is accurateElectric switchesPunchingFlexible circuits

The invention discloses a production process of a circuit board with silicone keys. The production process comprises the steps of injection molding of the silicone keys, gluing of a flexible circuit board, fitting molding of the silicone keys and the flexible circuit board, discharging inspection and warehousing. Compared with the prior art, the production process of the circuit board with the silicone keys provided by the invention has the advantages that the steps of opening a punching die, forming a bonding assembly line and a bonding jig, baking and the like are omitted; the injection molding step and the fitting molding step can be completed on a same molding die at the same time, so that the product manufacturing time is greatly saved, adverse conditions are reduced, the equipment investment of corresponding steps is saved, and the product production cost is greatly reduced.

Owner:INJECTION PRECISION RUBBER SUZHOU CO LTD

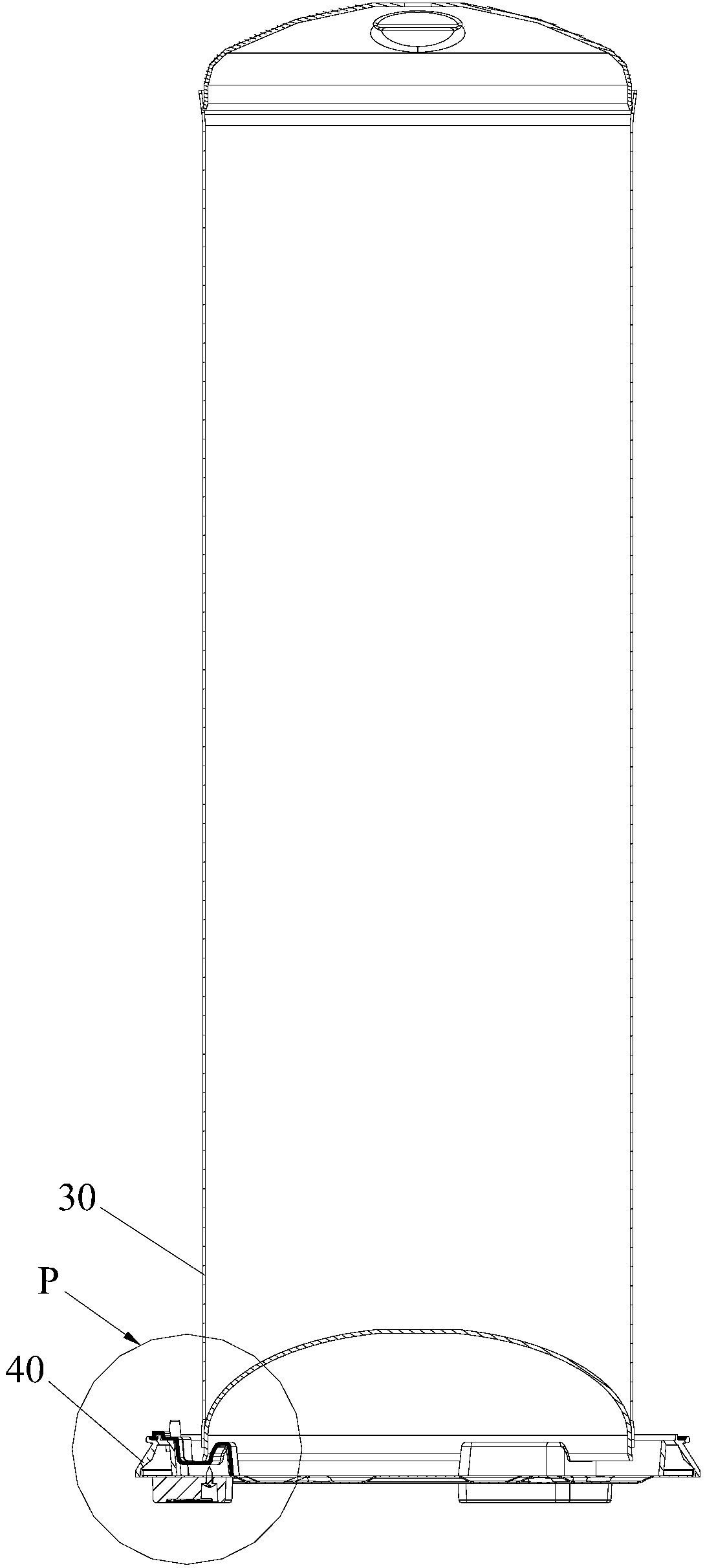

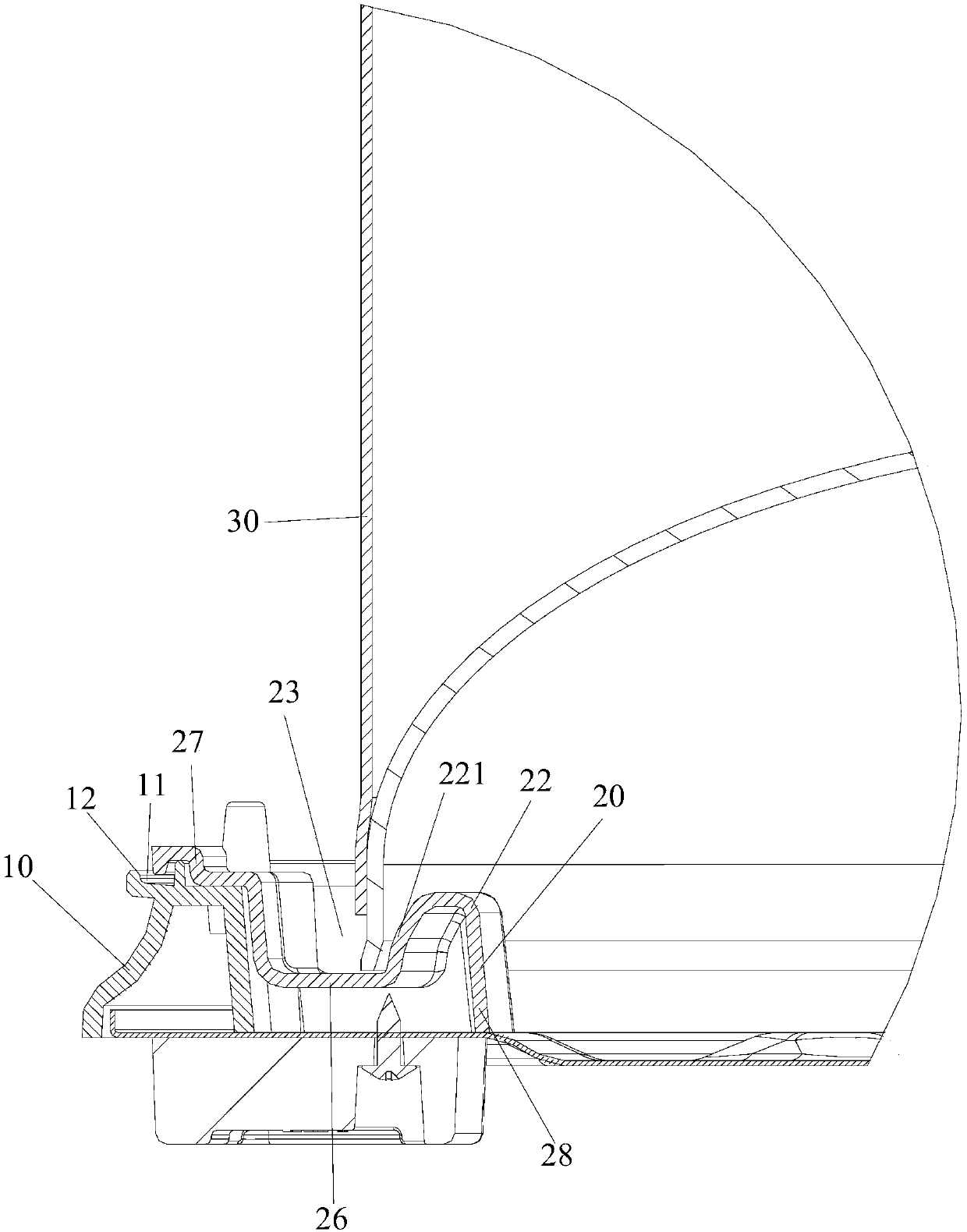

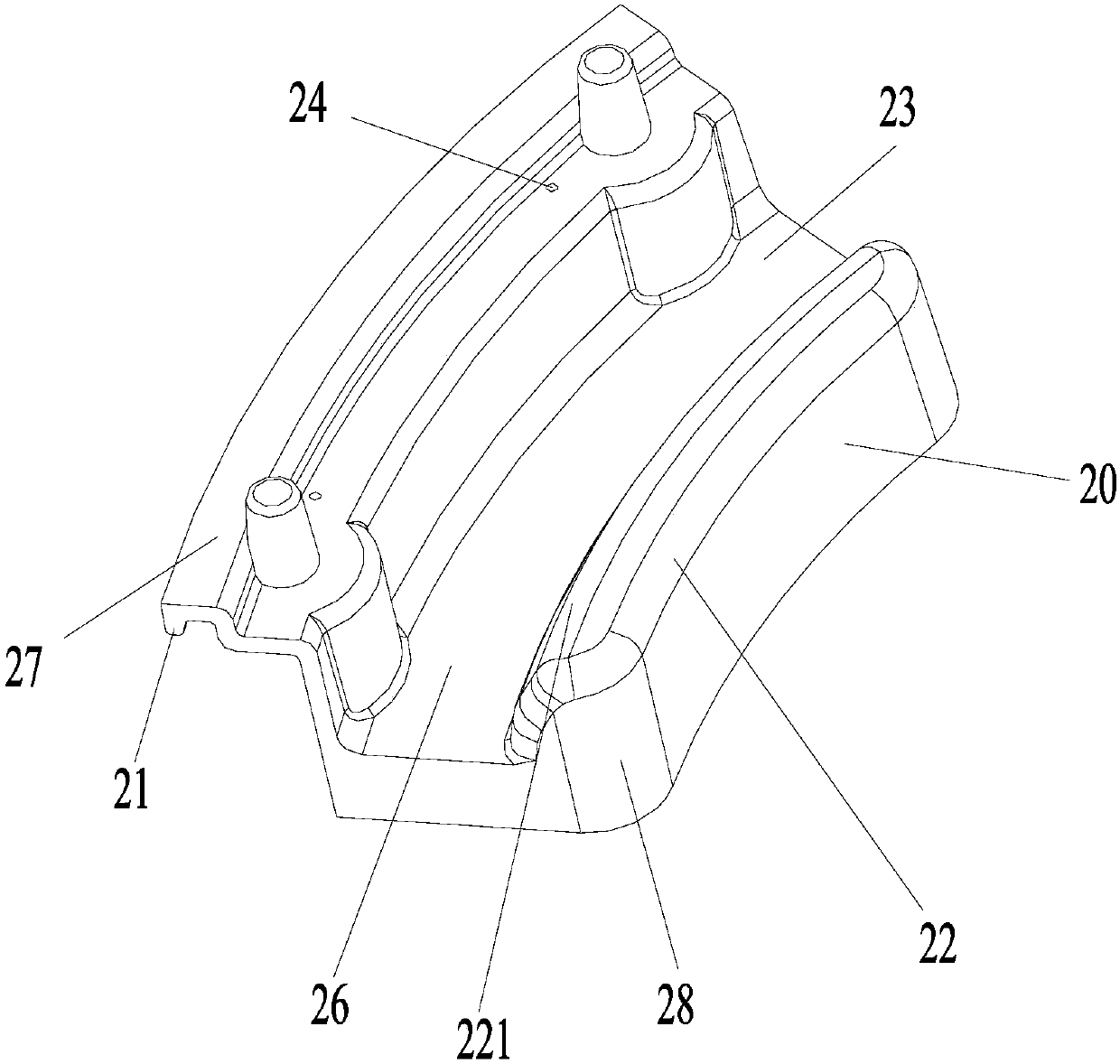

Baseplate module, water tank and water heater

The invention provides a baseplate module, a water tank and a water heater. The baseplate module comprises a support part and a base, wherein the support part is provided with a guide structure for guiding a liner; and the base is provided with at least one support part. The baseplate module solves the problem of low assembly positioning reliability of the liner in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

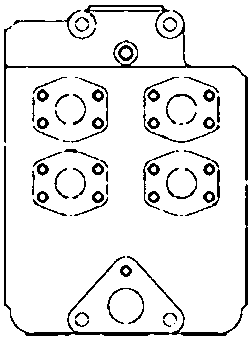

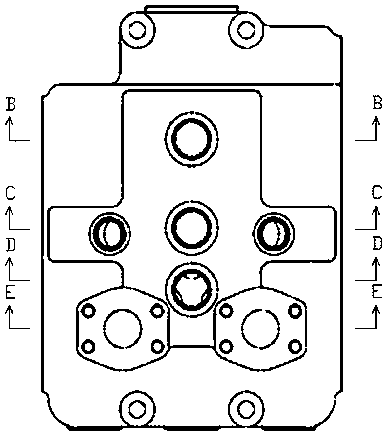

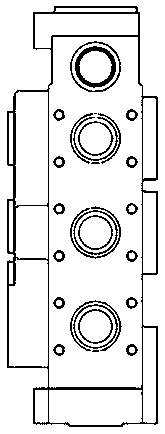

78A0406M valve body and processing technology thereof

ActiveCN108405803AGuaranteed dimensional accuracyAssembly positioning is accurateFoundry mouldsFoundry coresMaterials scienceCore strength

The invention relates to a 78A0406M valve body and a processing technology thereof. A precoated sand shell making technology is adopted to produce a pouring mold, and thus the size accuracy of a runner is ensured; a sand core is placed in the pouring mold to be assembled, and thus assembly and positioning accuracy of the sand core are ensured; and exhaust vents of the sand core are completely guided out through steel wires, the steel wires are pulled out after a base model is produced, smoothness of air vents is guaranteed, meanwhile, the sand core strength is enhanced through steel wire liners, stable molding of the sand core is ensured, and the sand core is not prone to deforming and fracturing.

Owner:南通华东油压科技有限公司

Auxiliary device and method for assembling belt pulley of engine snubber

PendingCN108098681AAssembly positioning is accurateAvoid damageMetal-working hand toolsSnubberEngineering

The invention discloses an auxiliary device for assembling a belt pulley of an engine snubber. The auxiliary device comprises a push rod; the front end surface of the push rod is matched with the rearend surface of an inner wheel of the belt pulley; a supporting shaft matched with an inner hole of the inner wheel is axially arranged at the front end of the push rod in an inserted mode; a clampingblock which extends in the axial direction is arranged on the rotating surface of the supporting shaft; clamping structures which are in clamping fit with a crankshaft positioning groove formed in the end part of a crankshaft and an inner wheel positioning groove located at the rear end of the inner wheel and corresponding to the crankshaft positioning groove are arranged at the front end and therear end of the clamping block; and a spring reset mechanism for driving the supporting shaft to slide back and forth in the axial direction is arranged between the push rod and the supporting shaft.The invention further discloses a method for assembling the belt pulley of the engine snubber. According to the technical scheme, the auxiliary device and method has the advantages of being reasonable in structural design, easy to manufacture, convenient to carry, good in practicability, simpler in operation, capable of improving the assembling efficiency and capable of facilitating press fitting, and assembling and positioning of the belt pulley are accurate.

Owner:GUANGXI YUCHAI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com