Welding ring sleeving machine

A set machine, welding ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of copper tube position deviation, welding ring assembly failure, low degree of automation, etc., to ensure the displacement path, reduce labor The effect of high cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

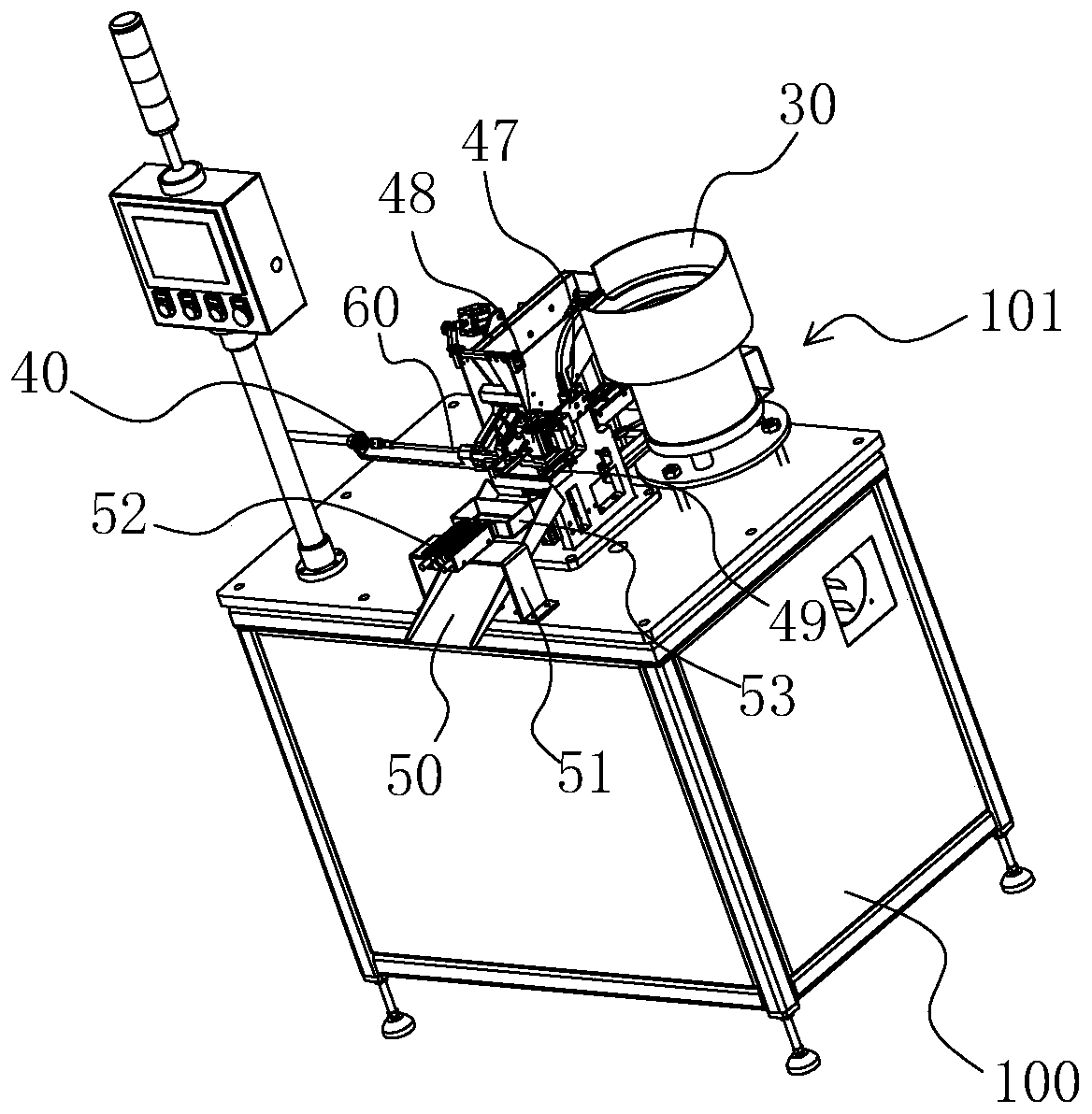

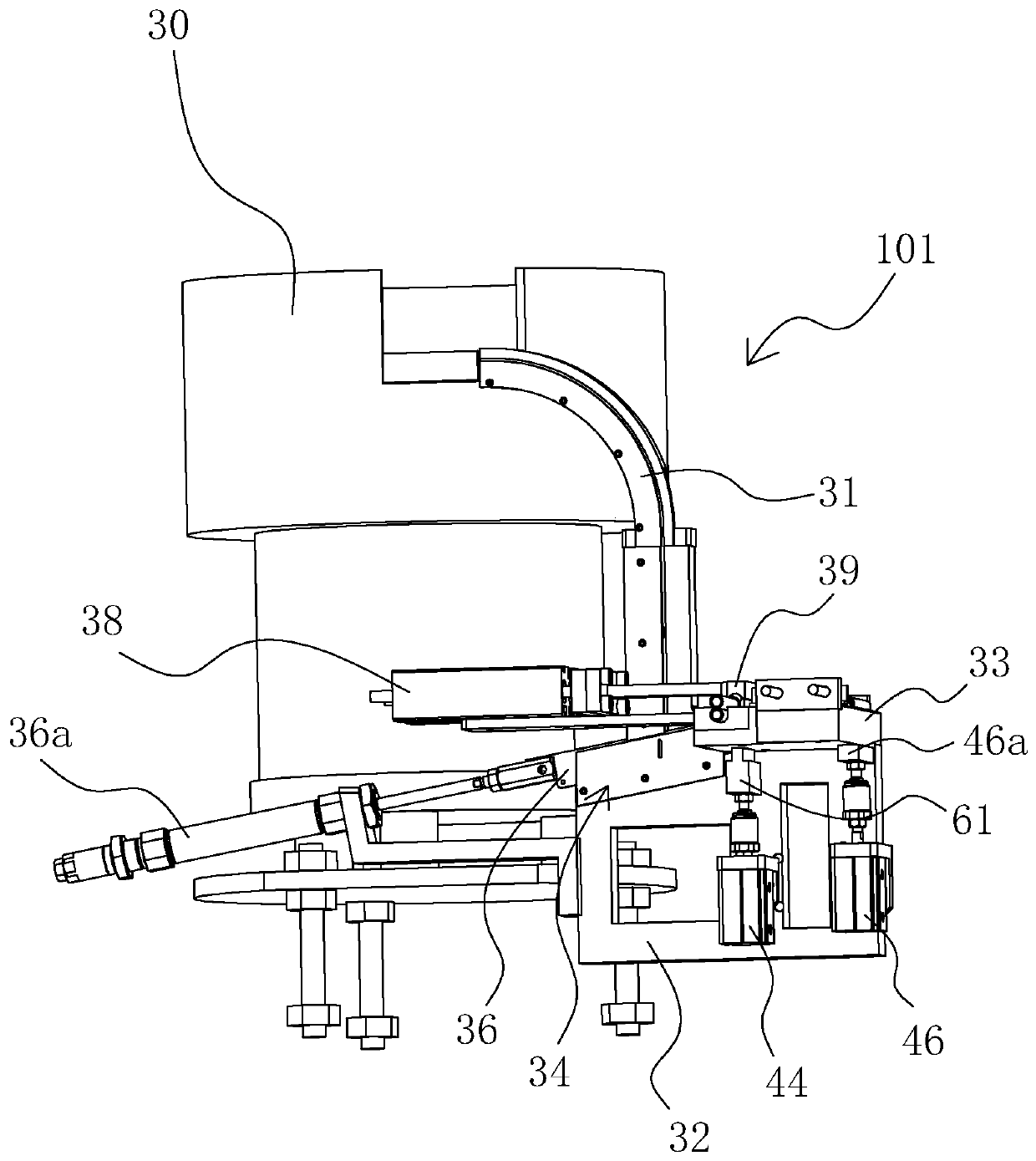

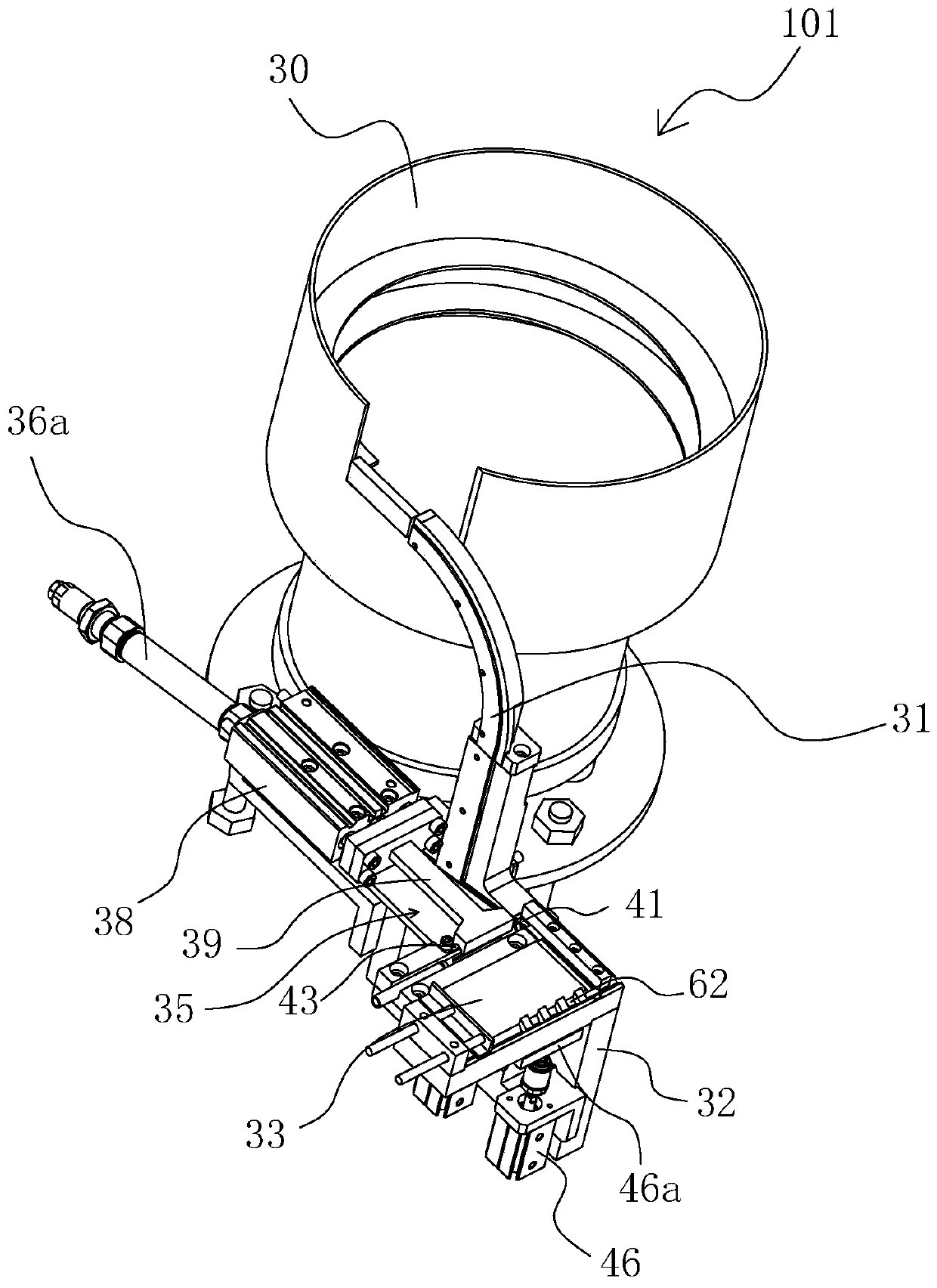

[0033] Such as Figure 1-9 As shown, a welding ring assembly machine includes a workbench 100. The workbench 100 is provided with a material storage box 1, and the abutment adjustment device that can reciprocate and linearly move along the horizontal direction is arranged in the described material storage box 1. Plate 2, the inside of the storage box 1 is rotatably provided with a tube transfer plate 3, and the storage box 1 is also provided with a pressure tube discharge assembly 4 corresponding to the position of the tube transfer plate 3, The workbench 100 is also provided with a collar feeding assembly mechanism 101 corresponding to the position of the material storage box 1 .

[0034]In this embodiment, the user puts the copper pipes into the material storage box 1 after aligning their heads and tails, and adjusts the abutment adjustment plate 2 so that the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com