Flat-face flange sealing gasket for automotive exhaust system

A technology for automotive exhaust systems and sealing gaskets, applied in exhaust devices, engine sealing, engine sealing devices, etc., can solve the problems of unreliable sealing, complex manufacturing process of sealing gaskets, and low assembly accuracy, achieving The effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

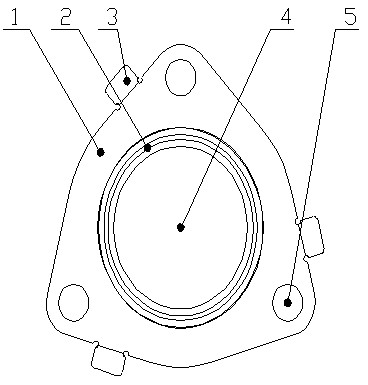

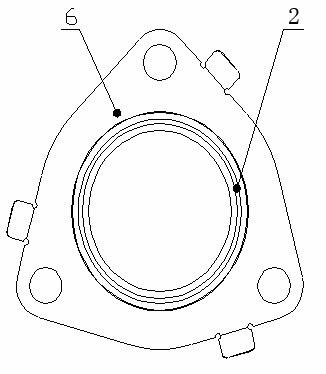

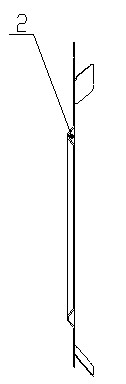

[0012] see figure 1 , figure 2 , The flat flange sealing gasket of the automobile exhaust system is composed of an upper piece 1 and a lower piece 6, both of which are made of 0.25mm stainless steel, and the two pieces have the same shape and are overlapped and welded as a whole. In the middle of the upper sheet 1 and the lower sheet 6, there is a through hole 4 consistent with the size of the center hole of the exhaust pipe joint flange 7. An assembly hole 5 corresponding to the position of the assembly hole on the exhaust pipe joint flange 7 is also punched on the periphery of the upper sheet 1 and the lower sheet 6 . More importantly, bosses 2 are respectively stamped around the through hole 4 on the opposite sides of the upper piece 1 and the lower piece 6, and the opposite sides of the upper piece 1 and the lower piece 6 are matched with the exhaust pipe joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com