Railway assembled hollow pier and construction method thereof

A construction method and hollow technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of violating the design principles of prefabricated bridges, heavy weight of prefabricated components, and difficulty in hoisting, so as to meet the light design concept and construction Convenient and fast, good overall mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

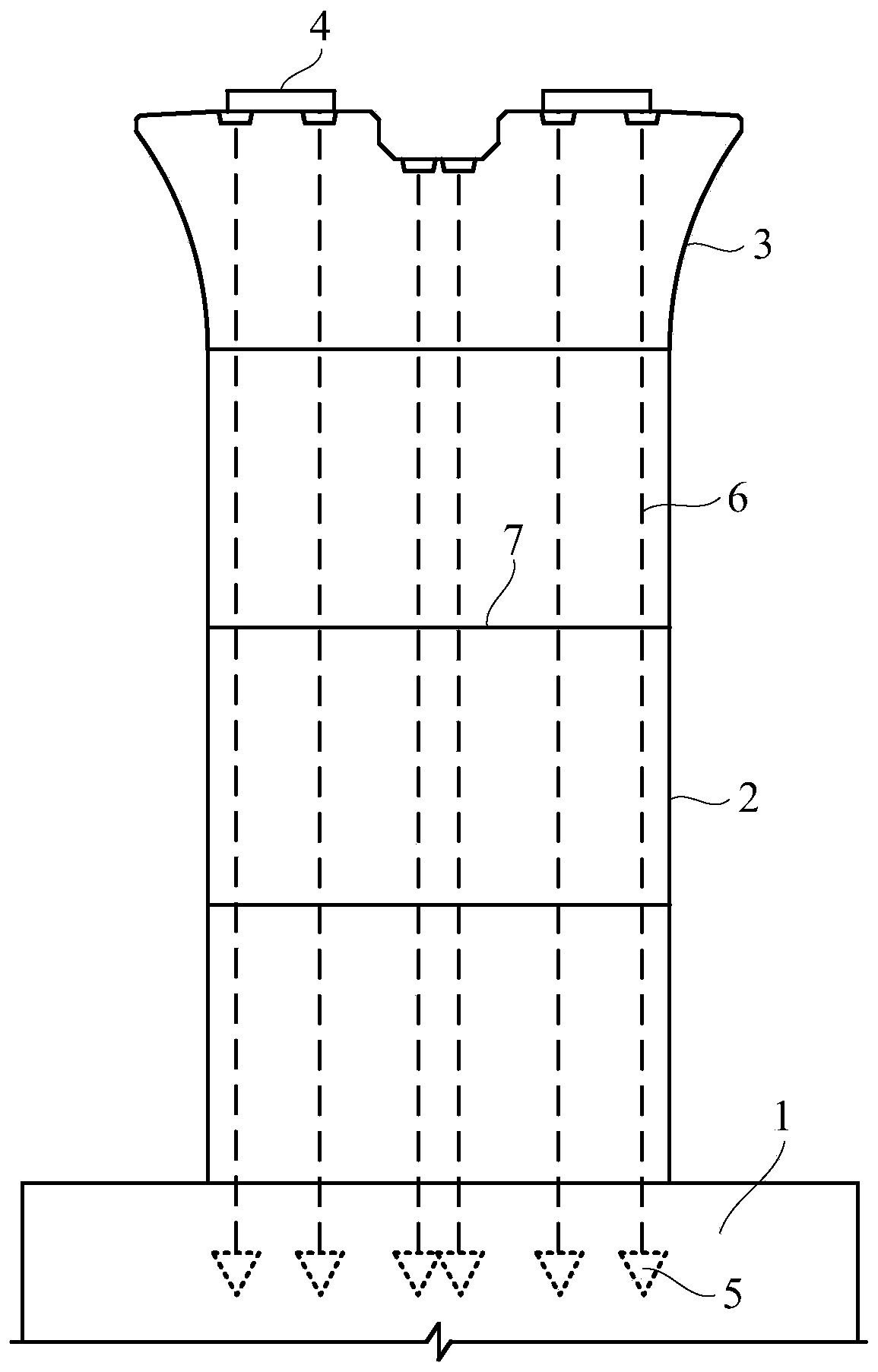

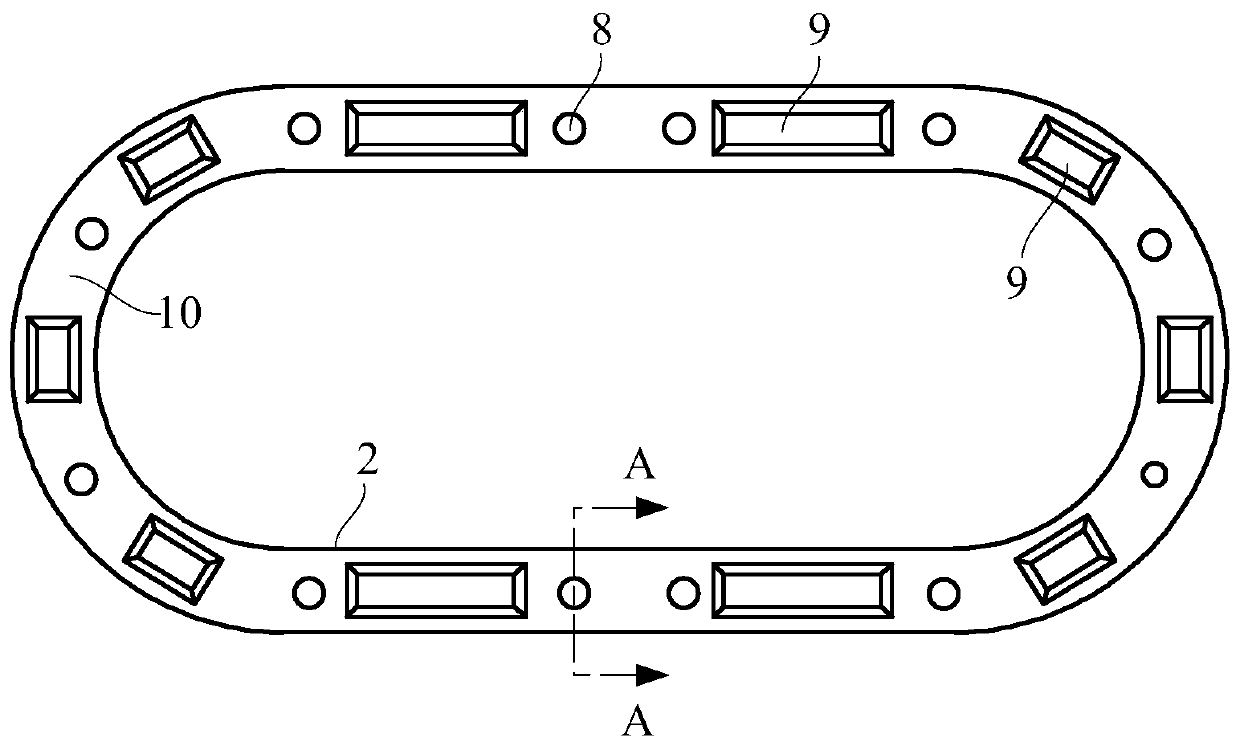

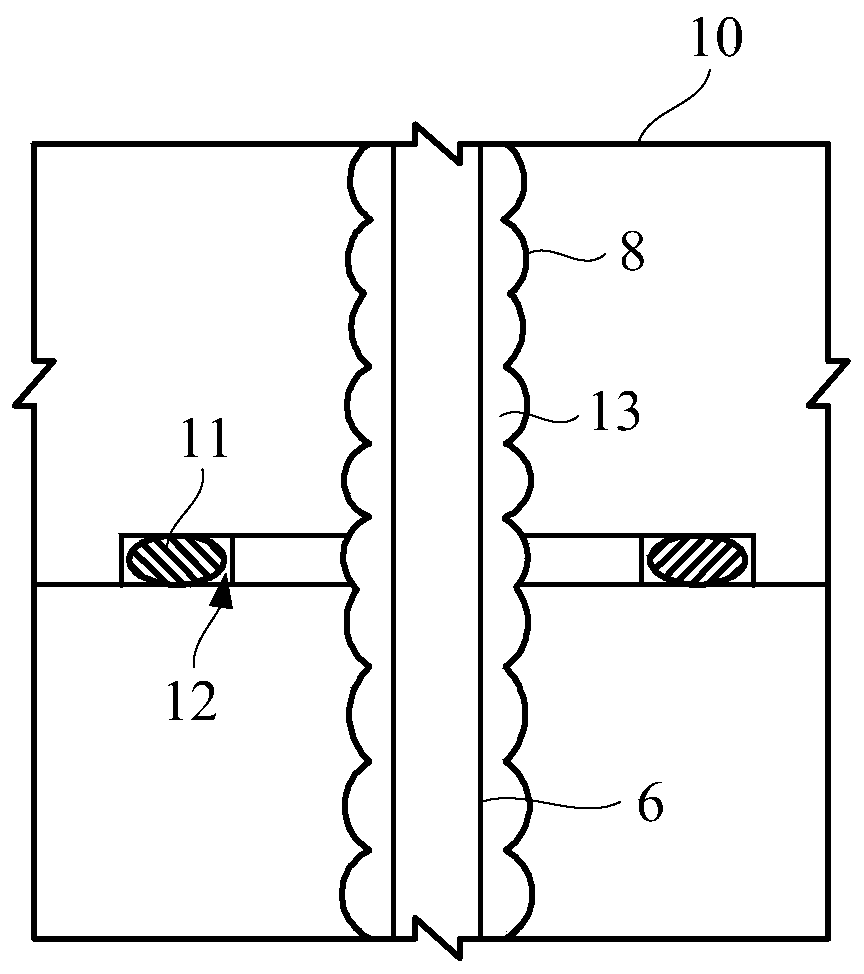

[0045] The embodiment of the present application provides a railway assembled hollow pier, such as figure 1 As shown in the structure, the railway assembled hollow pier includes a cap 1, a standard pier column segment 2, a pier top pier column segment 3 and a pad stone 4 connected sequentially from bottom to top; wherein, the cap 1 and the pad stone 4 are both It is made for on-site pouring; pier top pier column section 3 and standard pier column section 2 are prefabricated components; pier top pier column section 3 includes a solid section at the top and a hollow section at the bottom; standard pier column section 2 is Hollow tubular structure; cap 1 is used as the foundation of the railway assembled hollow bridge pier, standard pier column segment 2 and pier top pier column segment 3 constitute the pier column, pad stone 4 is used to support the bridge; installed on the pier top pier column segment 3 The number of standard pier column segments 2 between it and the cap 1 can ...

Embodiment 2

[0058] The embodiment of the present application also provides a construction method. When the construction method is used to construct the railway assembled hollow pier provided in the above embodiment, such as Figure 5 As shown, the construction method includes the following steps:

[0059] Step S100, prefabricating the standard pier column section 2 and the pier top pier column section 3; since the standard pier column section 2 and the pier top pier column section 3 can be prefabricated on site or in the beam field in advance, it only needs to be It only needs to be hoisted, which can greatly shorten the construction period of the bridge pier; the prefabricated standard pier column section 2 and pier top pier column section 3 can be carried out before construction, and can also be carried out at the same time as the construction of cap 1;

[0060] Step S200, pouring caps 1 on site. At the pier construction site, caps 1 need to be poured according to actual needs, and a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com