Quick disassembly and assembly annular walled rubber belt feeder

A dismountable, feeder technology, applied in the field of conveying machinery, can solve the problems of troublesome disassembly, maintenance and replacement of spare parts, equipment deformation failure, insufficient rigidity of the bracket, etc., to achieve the effect of convenient on-site installation, safe and reliable work, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

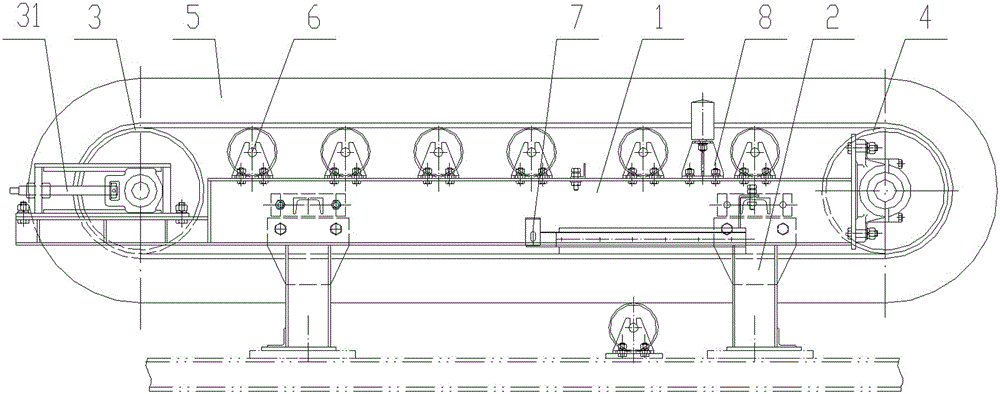

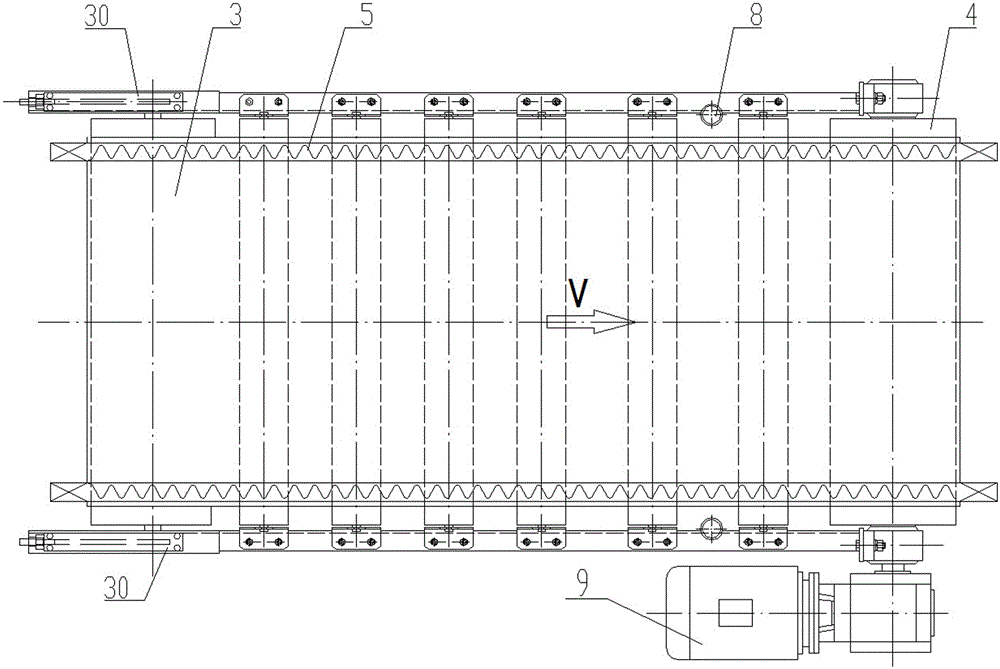

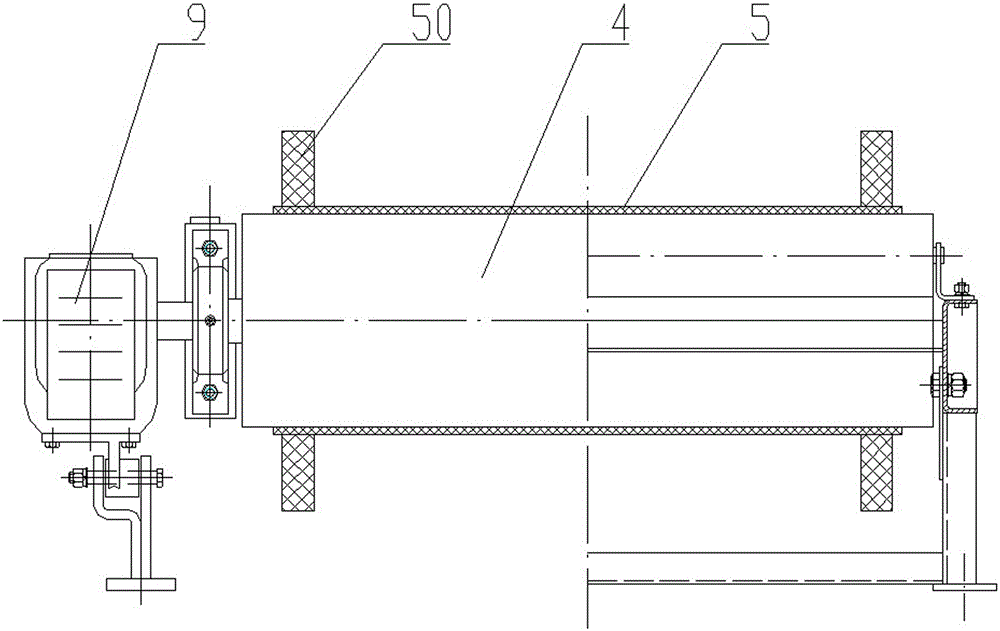

[0021] like figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the quick-detachable ring-shaped sidewall tape feeder of the present invention includes a frame 1, a plurality of legs 2 are arranged below the frame 1, and also includes a tensioning roller 3 and a driving roller 4. The tensioning At least one of the drum 3 and the drive drum 4 adopts a drum-shaped structure; an endless conveyor belt 5 is tensioned between the tension drum 3 and the drive drum 4, and an upper and lower support for carrying the endless conveyor belt 5 and materials is also included. The roller set 6 also includes a tensioning device connected with the tensioning drum 3, and also includes a power device.

[0022] The drum-shaped structure means that the diameter of the waist of the drum is greater than the diameters of both ends. In this embodiment, both the tension drum 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com