Chain accessory hybrid pushing assembly equipment

A technology for assembling equipment and accessories, applied in the direction of metal chains, etc., can solve the problem of single model of assembling chains, achieve high pushing efficiency, reduce the use of drivers, and achieve the effect of simple and stable positioning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content of the present invention, the present invention will be described in detail with reference to the accompanying drawings and embodiments. It should be understood that the embodiments are only for explaining the present invention and not limiting.

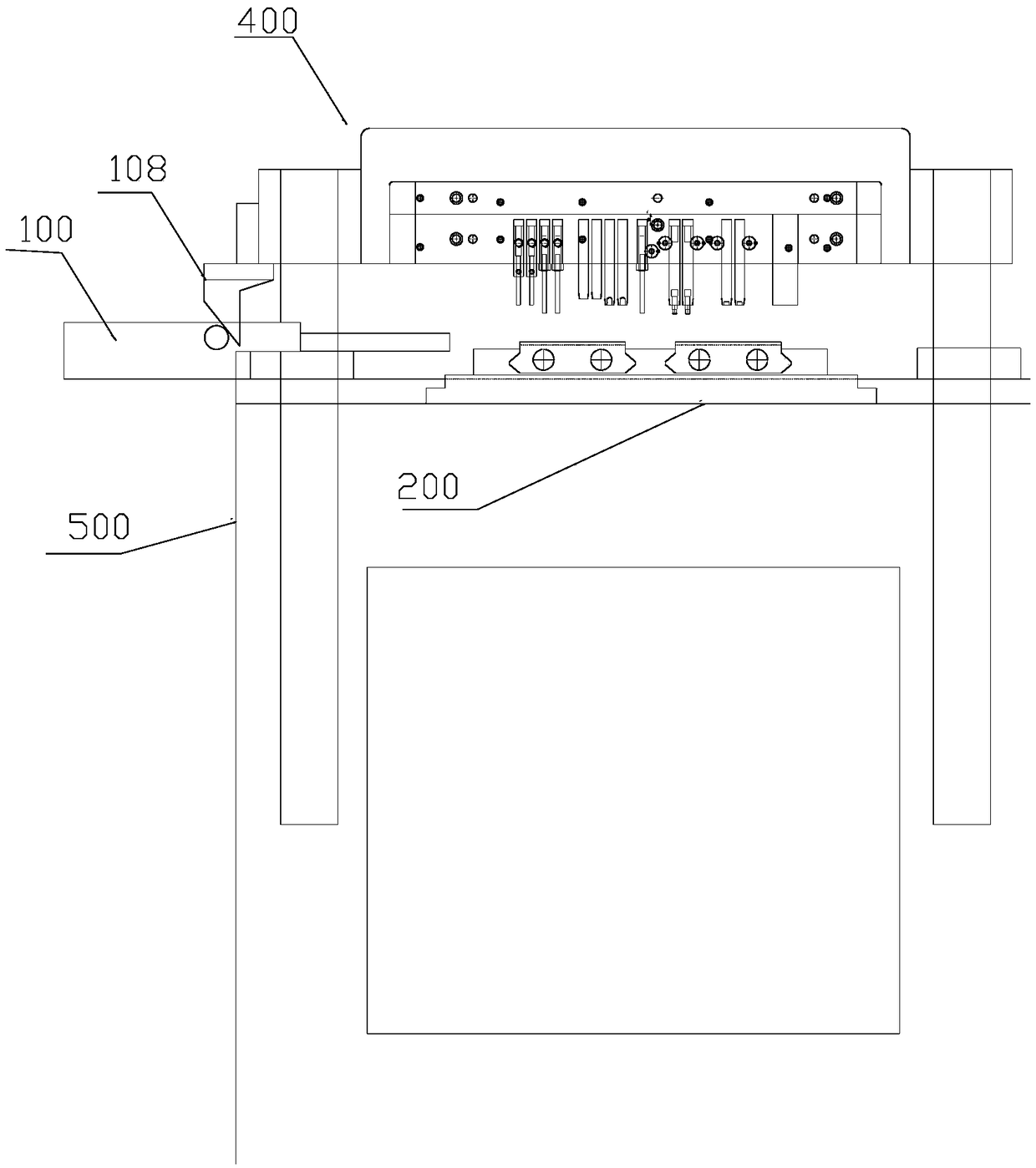

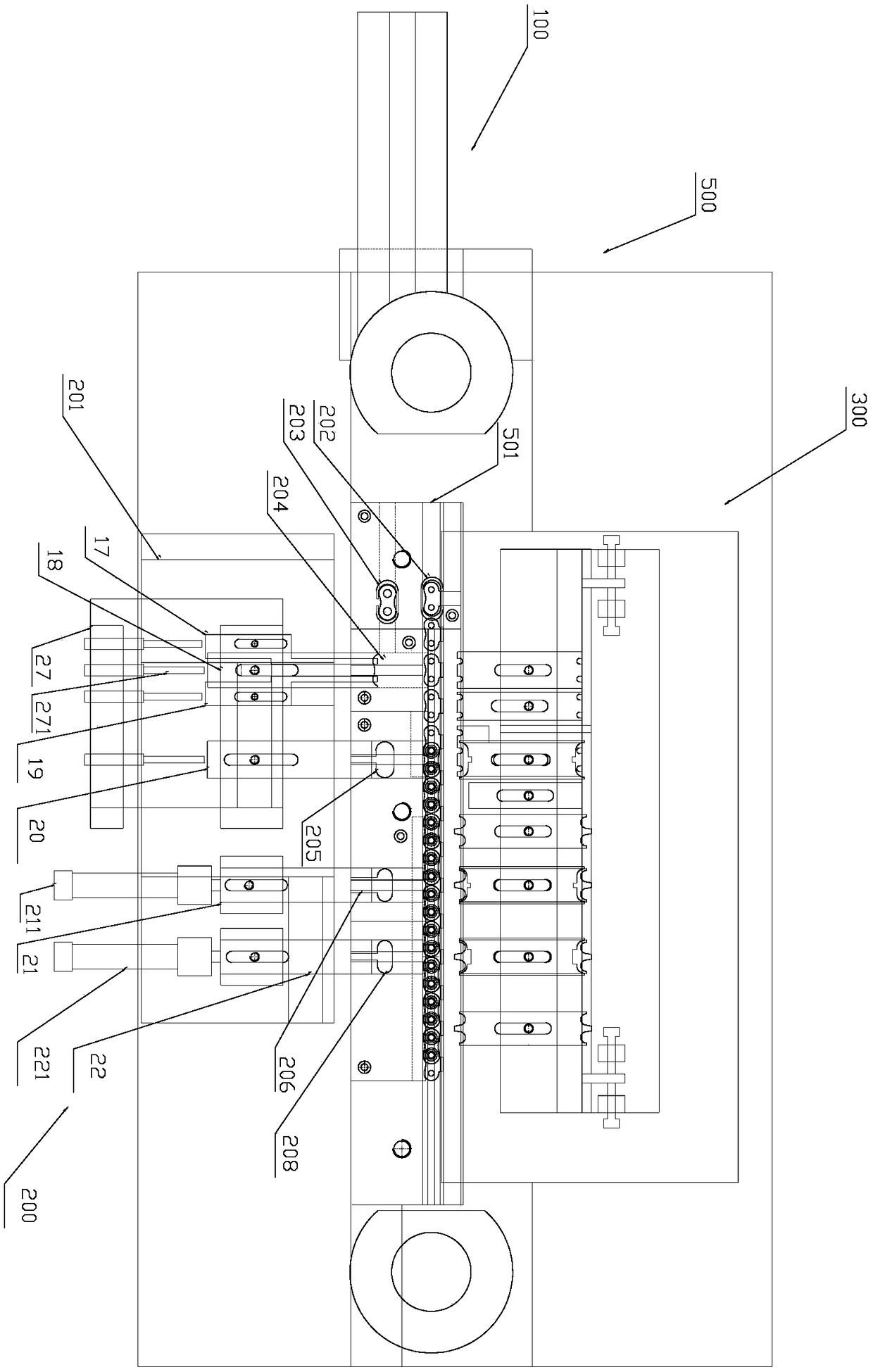

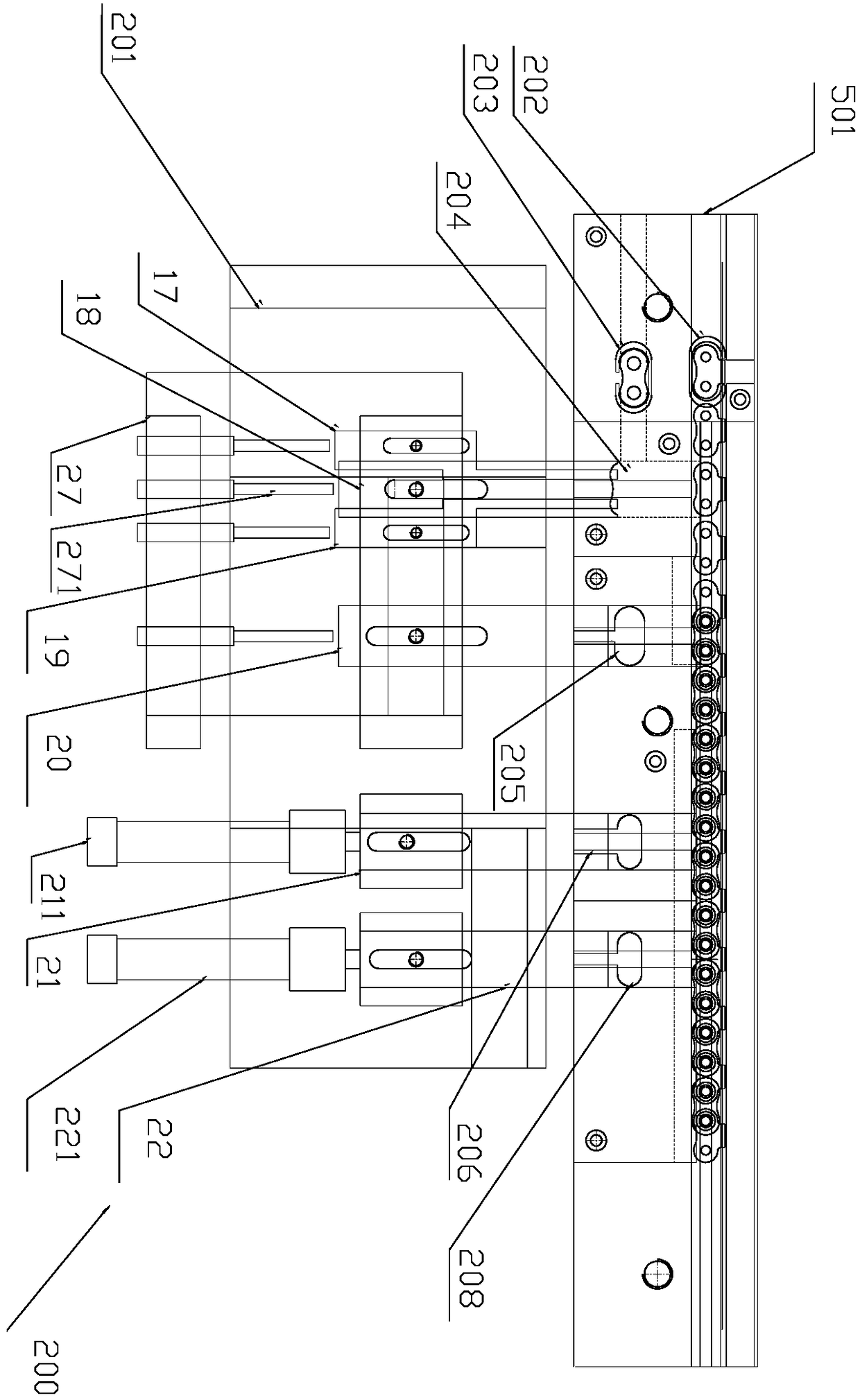

[0021] A hybrid push assembly equipment for chain accessories, comprising a workbench 500, the workbench 500 is a commonly used processing table for chain processing, the workbench drive structure, the two ends of the workbench 500 are provided with a guide shaft and a drive shaft, The guide rail shaft is slidably connected to the nailing beam 400, and one end of the drive shaft is connected to the nailing beam 400 and driving the nailing beam 400 to move up and down. The nailing beam 400 is provided with chain assembly and nailing.

[0022] The drive shaft includes a first drive shaft and a second drive shaft, which are respectively located near the two end positions on the axis of the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com