78A0406M valve body and processing technology thereof

A processing technology and valve body technology, which is applied in the field of 78A0406M valve body and its processing technology, can solve problems such as difficult and accurate positioning, complicated assembly of sand cores, and complex abortion of multi-way valve bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

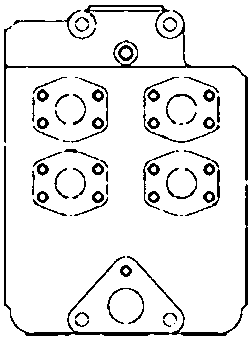

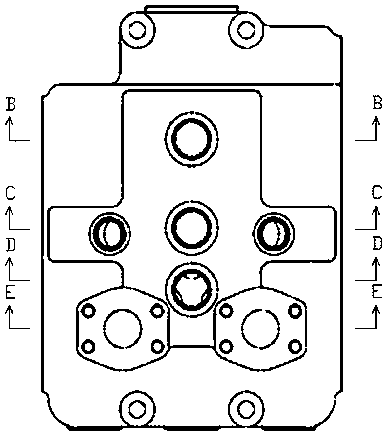

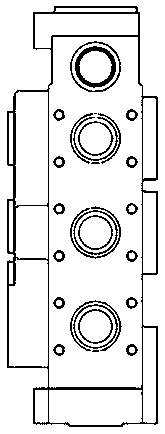

[0059] Such as Figure 1-11, a 78A0406M valve body, characterized in that: it includes a valve body; the valve body is designed in a block shape, five flow channel openings are designed in front of the valve body, and two flow channel openings are arranged longitudinally on the left side of the valve body; There are three runner ports arranged longitudinally on the right side of the valve body; one runner port is designed on the top of the valve body; three runner ports are arranged horizontally on the bottom surface of the valve body; seven runner ports are designed on the back of the valve body; There are four horizontal main flow channels, twelve longitudinal flow channels and four vertical flow channels inside the valve body. side and seven longitudinal passages arranged longitudinally on the rear side of the valve body, the four vertical passages include one vertically arranged above the valve body and three vertically arranged below the valve body, and the three vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com