Auxiliary device and method for assembling belt pulley of engine snubber

An auxiliary device and pulley technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of broken crankshaft small end, high labor intensity, low production efficiency, etc., and achieves improved assembly efficiency, reduced labor intensity, and good practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

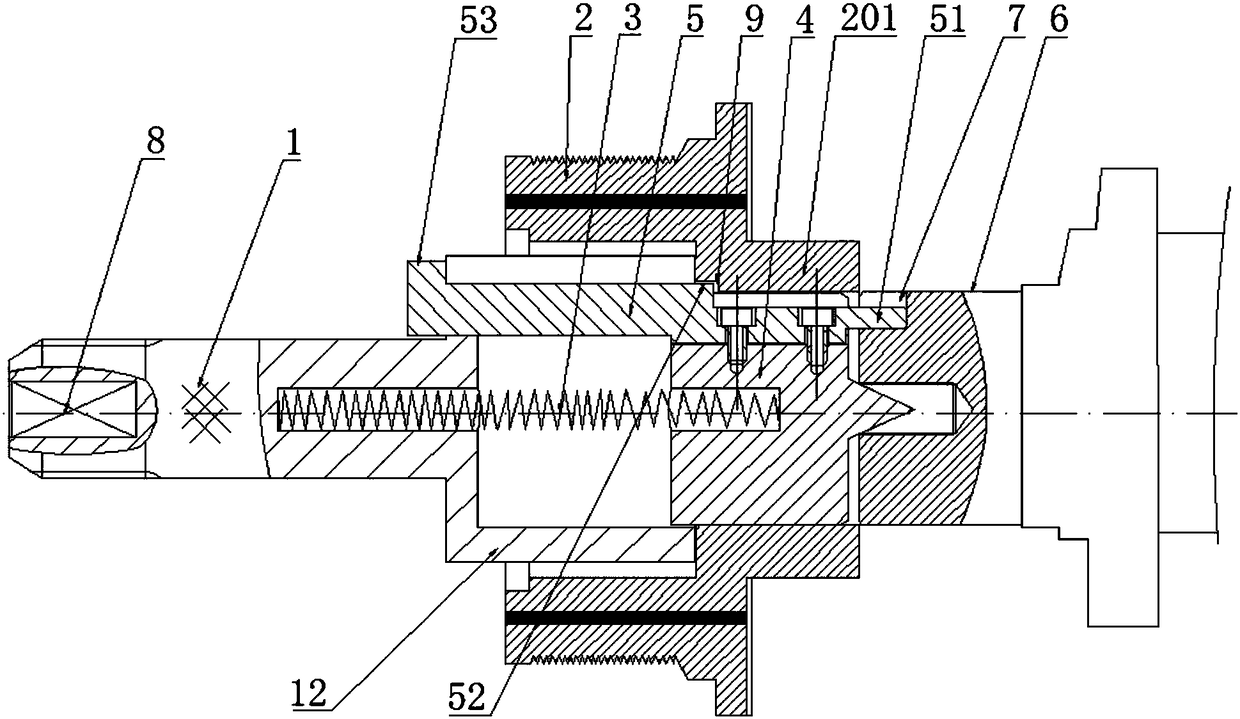

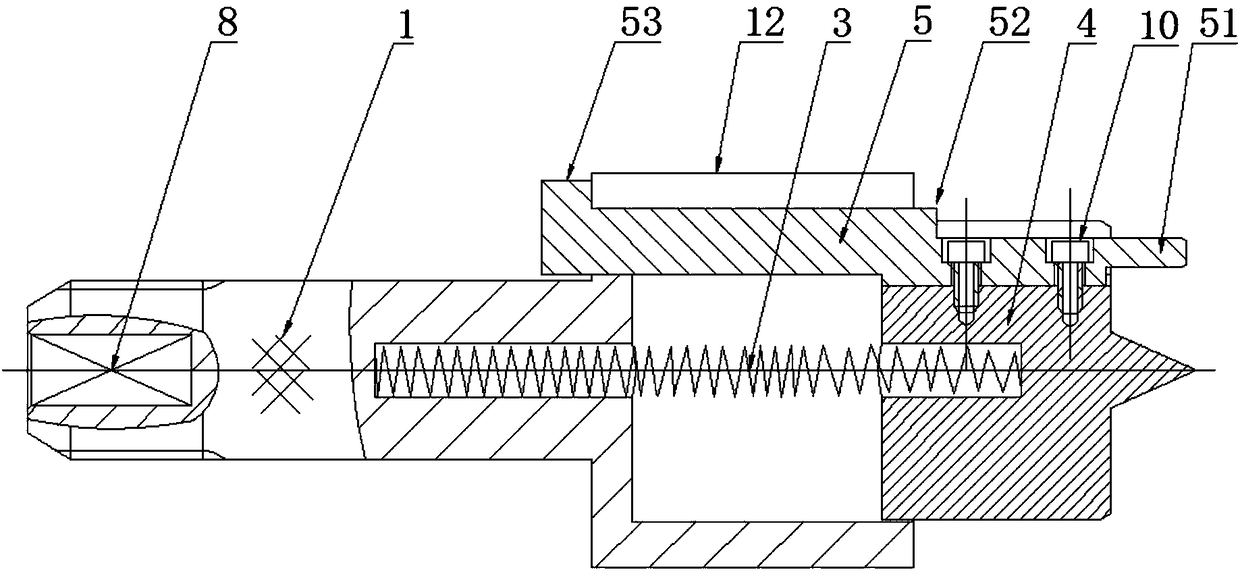

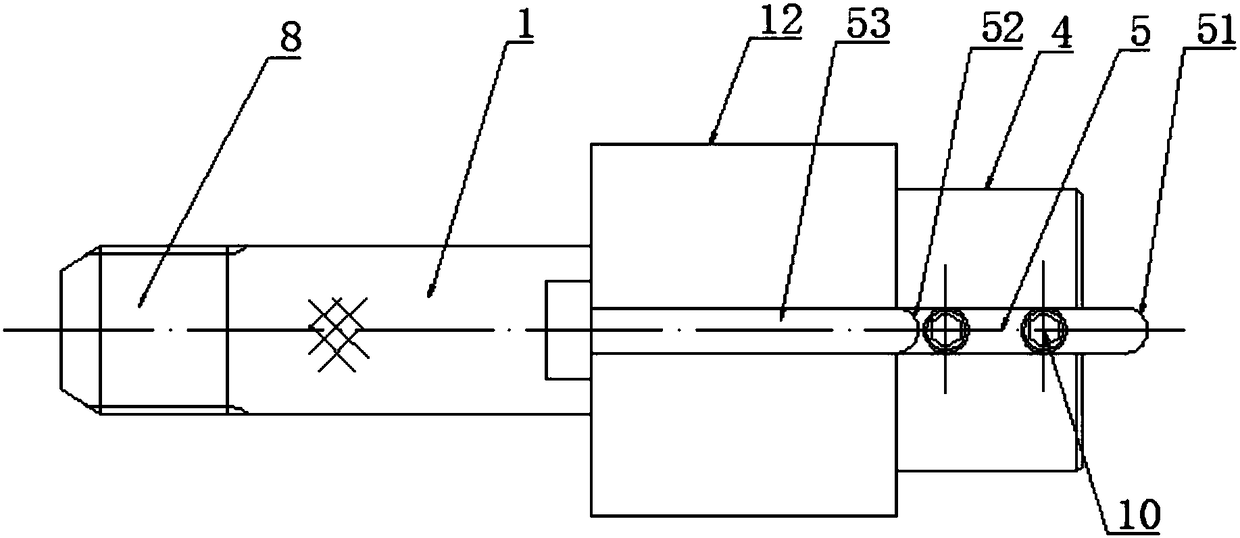

[0026] The specific embodiment of the present invention is like this: as Figure 1-7 As shown, an auxiliary device for engine shock absorber pulley assembly, including a push rod 1, the front end of the push rod 1 is compatible with the rear end of the inner wheel 201 of the pulley 2, and the front end of the push rod 1 is inserted axially. The support shaft 4 that is adapted to the inner hole of the inner wheel 201, the rotating surface of the support shaft 4 is provided with an axially extending clamping block 5, the clamping block 5 is a square bar, and the front and rear ends of the clamping block 5 are respectively provided with The engaging structure that engages the crankshaft positioning groove 7 at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com