Cast iron and glass fiber composite double-layer structure cable protection sleeve

A cable protection sleeve and composite double-layer technology, applied in the direction of electrical components, etc., can solve the problems of poor corrosion resistance and increased costs, and achieve the effects of wide application range, convenient handling, and reduced industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

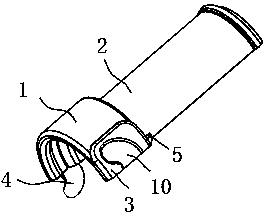

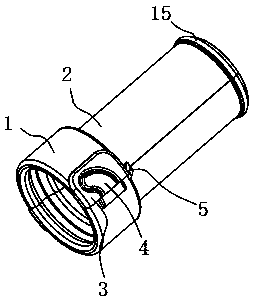

[0042] refer to Figure 1-3 , a cast iron glass fiber composite double-layer structure cable protection sleeve, including a thick connecting pipe 1, a thin connecting pipe 2 and a connecting ring 15, between the thick connecting pipe 1 and the thin connecting pipe 2, the thin connecting pipe 2 and the connecting ring 15 They are all integrally formed. The thick connecting pipe 1 is arranged in a semi-cylindrical shape. The thick connecting pipe 1, the thin connecting pipe 2 and the connecting ring 15 are equipped with an inner layer 7 that matches the inner layer 7. The inner layer 7 is close to the inner wall of the thin connecting pipe 2. One side of the tube is symmetrically provided with four snapping points 9, and the inner wall of the thin connecting tube 2 is provided with a snapping groove 8 matching the snapping point 9, and the snapping groove 8 is stuck on the snapping point. 9, through the mechanical positioning of four points, the installation is faster, and the t...

Embodiment 2

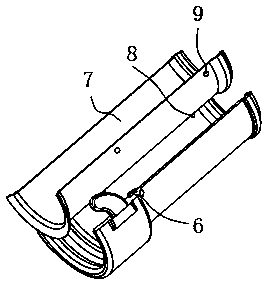

[0046] refer to Figure 4-7 , a cast iron glass fiber composite double-layer structure cable protection sleeve, including a thick connecting pipe 1, a thin connecting pipe 2 and a connecting ring 15, between the thick connecting pipe 1 and the thin connecting pipe 2, the thin connecting pipe 2 and the connecting ring 15 They are all integrally formed. The thick connecting pipe 1, the thin connecting pipe 2 and the connecting ring 15 are equipped with an inner layer 7 that matches them. The inner layer 7 is symmetrically provided with four clips on one side of the inner wall of the thin connecting pipe 2. Positioning bump 9, the inner wall of the thin connecting tube 2 is provided with a locking groove 8 that matches the locking bump 9, and the locking groove 8 is stuck on the locking bump 9, through four-point mechanical positioning , so that the installation is more rapid, the thin connecting pipe 2 and the thick connecting pipe 1 are also symmetrically provided with a reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com