Optical transceiver module assembling method

A technology of optical transceiver components and assembly methods, which is applied to the coupling of optical elements, optical waveguides, light guides, etc., can solve the problems of low assembly and matching efficiency, unobjective evaluation criteria for the assembly process of optical transceiver components, etc., and achieve the effect of accurate assembly positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

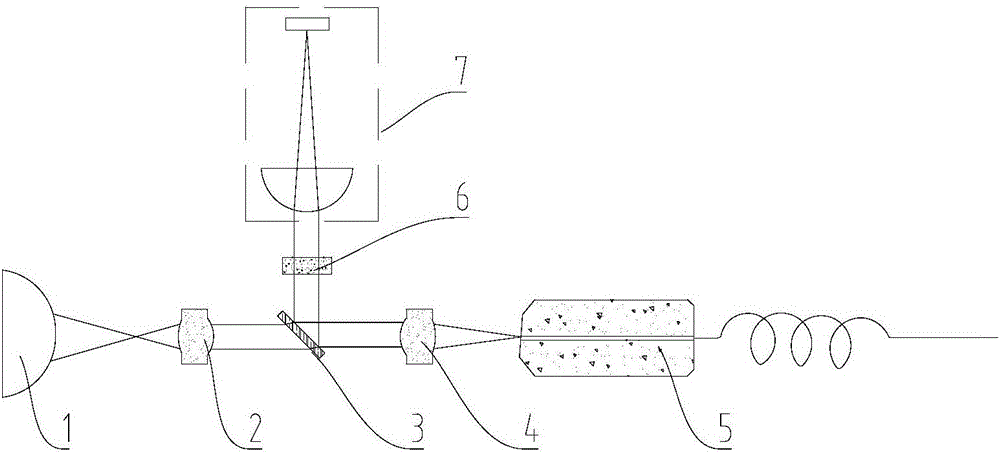

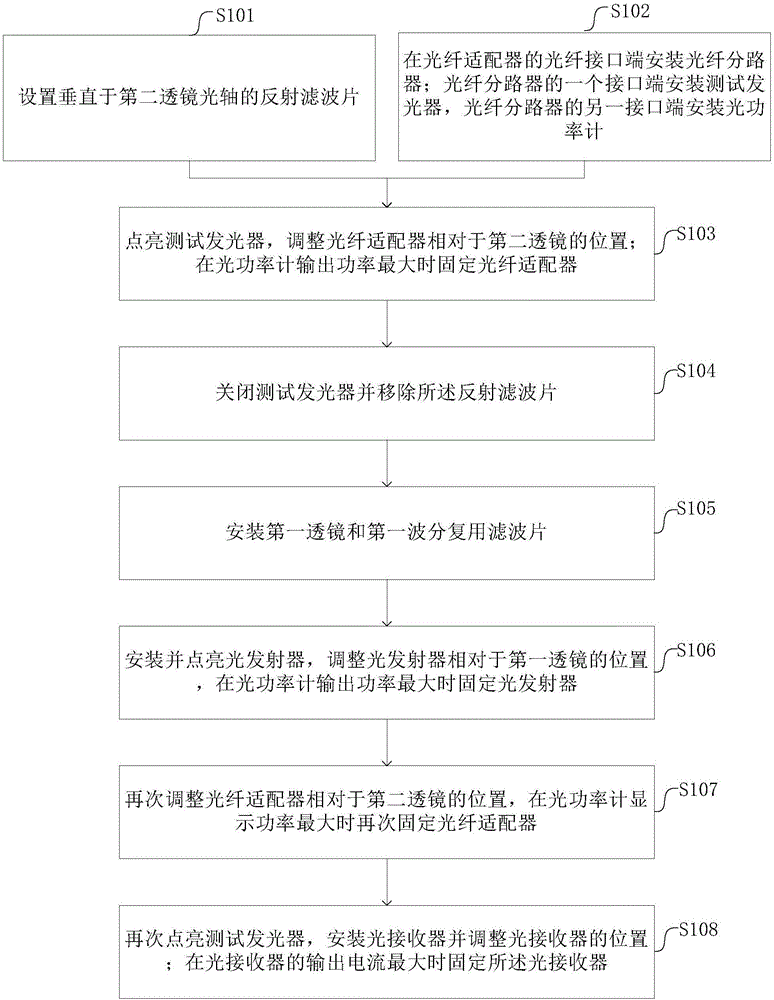

[0037] image 3 It is a flow chart of the method for assembling the optical transceiver assembly in the first embodiment. Such as image 3 , The method for assembling the optical transceiver assembly in the first embodiment includes the following steps.

[0038] S101: setting the reflective filter 8 perpendicular to the optical axis of the second lens 4 .

[0039] S102: Install a fiber optic splitter 9 at the fiber interface end of the fiber optic adapter 5; install a test light emitter 10 at one interface end of the fiber optic splitter 9, and install an optical power meter 11 at the other interface end of the fiber optic splitter 9.

[0040] Figure 4 is a schematic diagram of positioning the fiber optic adapter in the first embodiment, such as Figure 4 , the optical fiber splitter 9 is installed on the optical fiber interface end of the optical fiber adapter 5, and is connected with the optical fiber adapter 5 through an optical fiber. One interface end of the optical...

no. 2 example

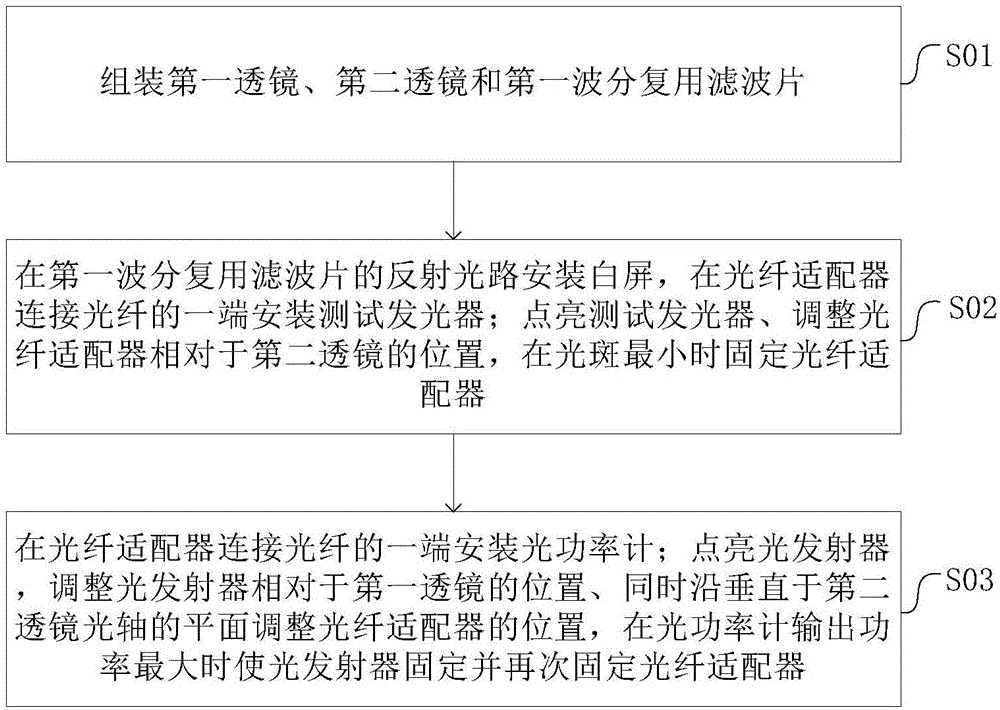

[0057] Image 6 It is a flow chart of the method for assembling the optical transceiver assembly in the second embodiment. Such as Image 6 , The method for assembling the optical transceiver assembly in the second embodiment includes the following steps.

[0058] S201: Assemble the first lens 2, the second lens 4 and the first wavelength division multiplexing filter 3.

[0059] In this embodiment, the first lens 2, the second lens 4 and the first wavelength division multiplexing filter 3 are fixed by mechanical positioning to form the first assembly, wherein the light parallel to the optical axis of the first lens 2 passes through the first wavelength division After the filter 3 is multiplexed, it is parallel to the optical axis of the second lens 4 .

[0060] S202: Install an optical fiber splitter 9 at the optical fiber interface end of the optical fiber adapter 5, install a test light emitter 10 for emitting test light at one interface end of the optical fiber splitter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com