Transformer iron core capable of improving assembly efficiency

A transformer core and assembly efficiency technology, applied in the field of transformers, can solve the problems of unfavorable step-over-lap core development, manpower consumption, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

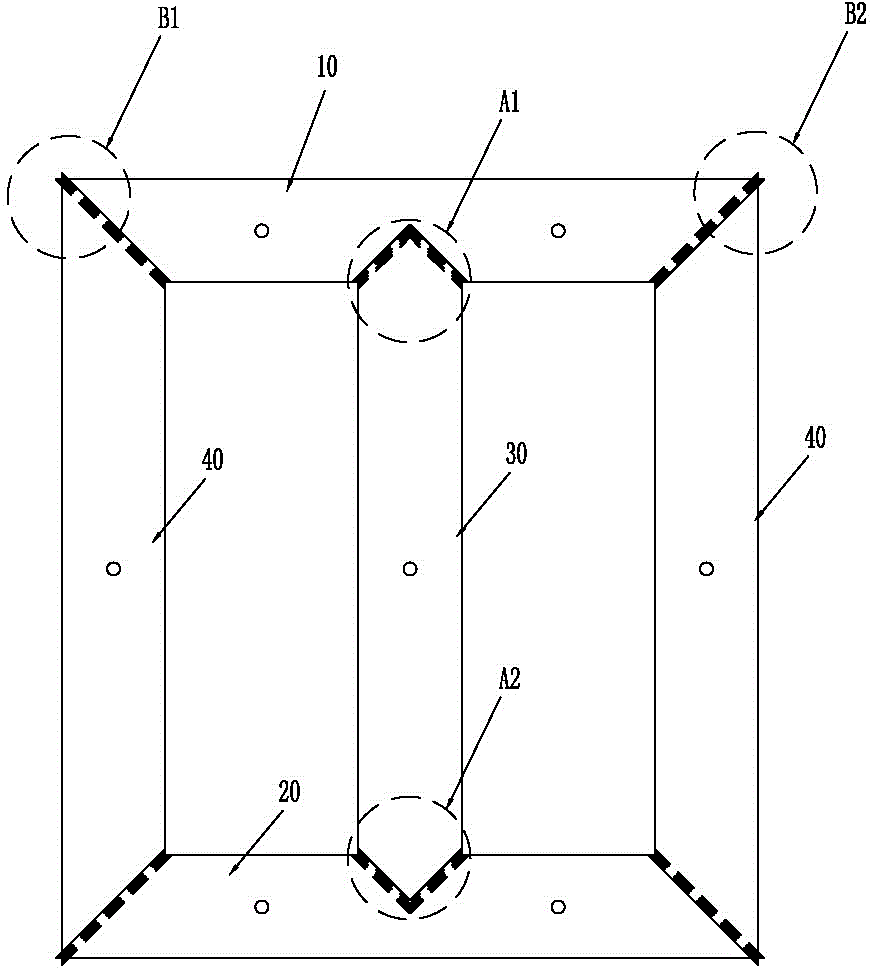

[0043] Please refer to Figure 1 to Figure 14 As shown, it shows the specific structure of the embodiment of the present invention.

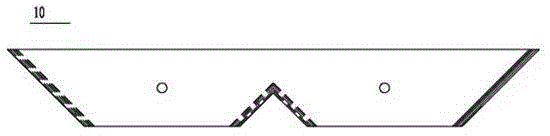

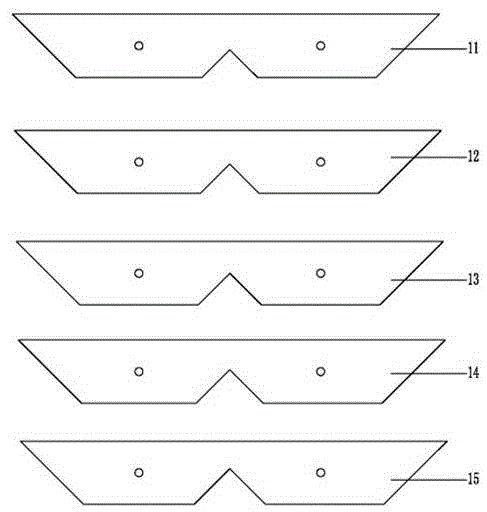

[0044] Such as figure 1 As shown, the transformer core includes one or more laminated layers stacked in sequence, and each laminated layer includes upper yoke laminated sheets 10 with the same number of stacked sheets (number of stacked sheets N≧2), Lower yoke laminations 20, center column laminations 30, and side column laminations 40; The laminations 40 are all multi-stage steps, and the number of overlapping sheets of the steps is a positive integer multiple of the number of steps; usually designed to be more than three steps, preferably designed to be five steps, then the aforementioned steps The number of lapped and stacked sheets is a positive integer multiple of five of the step number.

[0045] Such as Figure 2a , Figure 2b and Figure 9 to Figure 11 As shown, the upper yoke lamination 10 includes several layers of upper yoke pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com